What Is TPU Material?

Indice dei contenuti

Sintesi

- TPU is a versatile material combining the properties of rubber and plastic.

- It is created through a polyaddition reaction involving diisocyanates and diols.

- TPU is known for its flexibility, strength, and resistance to abrasion and chemicals.

- It is considered safe for use in consumer products, including medical devices.

- TPU filament is popular in 3D printing for creating flexible, durable structures.

- In consumer electronics, TPU is used for protective cases and connectors.

- Compared to other plastics, TPU offers superior durability and performance.

- Injection molding is a common process for manufacturing TPU products.

- TPU’s durata extends product lifespan and supports sustainability.

- Future trends include expanding applications in automotive, healthcare, and sports industries.

Whether you’re a manufacturer, designer, or consumer, understanding TPU can help you make informed decisions about the materials you use and the products you create.

What is TPU and Why is it Important?

TPU is a versatile material that bridges the gap between rubber and plastic. Its unique properties make it suitable for a wide range of applications, from flexible phone cases to durable industrial components. The importance of TPU lies in its ability to combine flexibility with strength, offering solutions that other materials cannot match. For instance, TPU’s elasticity allows it to absorb shocks and impacts, protecting delicate items like electronics from damage.

How is TPU Made? Understanding the Composition

The production of TPU involves a chemical reaction known as polyaddition, where a diisocyanate reacts with one or more diols. This process creates a polymer with alternating hard and soft segments, giving TPU its distinctive properties. The hard segments provide strength and rigidity, while the soft segments offer flexibility and elasticity. By adjusting the ratio of these segments, manufacturers can tailor TPU to meet specific requirements, such as increased flexibility for wearable devices or enhanced hardness for industrial applications.

What are the Properties of TPU?

TPU’s properties make it a standout material in various industries. Its high tensile strength ensures that products made from TPU can withstand significant stress without breaking. The material’s elasticity allows it to stretch and return to its original shape, making it ideal for applications that require flexibility. Additionally, TPU’s resistance to oil, grease, and abrasion ensures that it maintains its performance even in challenging environments. These properties make TPU a reliable choice for products that need to endure wear and tear over time.

Is TPU Safe for Use?

Safety is a top priority when selecting materials for consumer products, and TPU meets the necessary standards. It is non-toxic and does not release harmful chemicals, making it safe for use in products that come into contact with skin, such as medical devices and wearable technology. TPU’s safety credentials have made it a popular choice in industries where consumer health and safety are paramount.

How is TPU Used in 3D Printing?

TPU filament is a game-changer in the world of 3D printing. Its flexibility and strength allow for the creation of complex structures that can withstand wear and tear. TPU filament is particularly useful for printing items that require elasticity, such as phone cases, shoe soles, and flexible joints. The ability to print with TPU opens up new possibilities for designers and engineers, enabling them to create innovative products that were previously difficult to manufacture.

What are the Applications of TPU in Consumer Electronics?

In the consumer electronics industry, TPU is used for protective cases, cables, and connectors. Its ability to absorb impact and resist abrasion makes it ideal for protecting delicate electronic components. TPU’s flexibility also allows for innovative designs that enhance the functionality and aesthetics of electronic devices. For example, TPU cases can provide a secure grip and shock absorption, protecting smartphones from accidental drops.

How Does TPU Compare to Other Plastics?

Compared to other plastics, TPU offers a unique combination of flexibility and strength. While materials like TPE (Thermoplastic Elastomer) share some similarities with TPU, TPU’s superior abrasion resistance and durability set it apart. This makes TPU a preferred choice for applications that demand high performance and longevity. For instance, TPU’s resistance to wear and tear makes it ideal for products that are subject to frequent use, such as sports equipment and footwear.

What is the Role of TPU in Injection Molding?

Injection molding is a common manufacturing process for TPU, allowing for the mass production of complex shapes with high precision. TPU’s melt-processable nature makes it ideal for injection molding, enabling the creation of products with intricate designs and consistent quality. This process is widely used in industries such as automotive and consumer electronics, where precision and efficiency are critical.

How Does TPU Enhance Durability in Products?

The durability of TPU is one of its standout features. Products made with TPU can withstand harsh conditions, including exposure to chemicals, UV light, and extreme temperatures. This durability extends the lifespan of products, reducing the need for frequent replacements and contributing to sustainability. For example, TPU’s resistance to UV light makes it suitable for outdoor applications, where exposure to sunlight can degrade other materials.

What are the Future Trends in TPU Applications?

As technology advances, the applications of TPU continue to expand. Innovations in TPU processing and formulation are leading to new uses in industries such as automotive, healthcare, and sports equipment. The versatility and adaptability of TPU make it a material with significant potential for future developments. For instance, TPU’s ability to be recycled and reused aligns with the growing demand for sustainable materials, making it an attractive option for environmentally conscious manufacturers.

Commenti

Tag

L'idrogel è adatto ai telefoni?

Conoscendo le differenze tra le pellicole protettive in idrogel e quelle in vetro temperato, potrai prendere una decisione consapevole, quella più adatta alle tue esigenze.

Pratiche eco-compatibili nella produzione di protezioni per schermi

Le pratiche ecologiche nella produzione di protezioni per schermi mirano a ridurre l'impatto ambientale e a soddisfare la crescente domanda di sostenibilità da parte dei consumatori attraverso innovazioni nei materiali e nei processi.

Come scegliere il giusto film idrogel flessibile per il vostro prodotto

I film idrogel flessibili sono materiali versatili, caratterizzati da un elevato contenuto d'acqua e da un'elevata elasticità, che ne consentono l'uso in diversi campi, tra cui la medicina, l'elettronica e il rilevamento ambientale.

Buick Envision 2024 GPS Navigation Tempered Glass

Our Buick Envision 2024 Navigation Protector offers superior protection for your new SUV’s display.

Come riparare lo schermo rotto del telefono

Grazie a questi suggerimenti e trucchi, potrai gestire in modo efficiente gli schermi rotti ed evitare spese inutili.

Trovate tutte le conoscenze e le tendenze dal nostro blog, ottenete il prezzo all'ingrosso e la migliore qualità dalla nostra fabbrica.

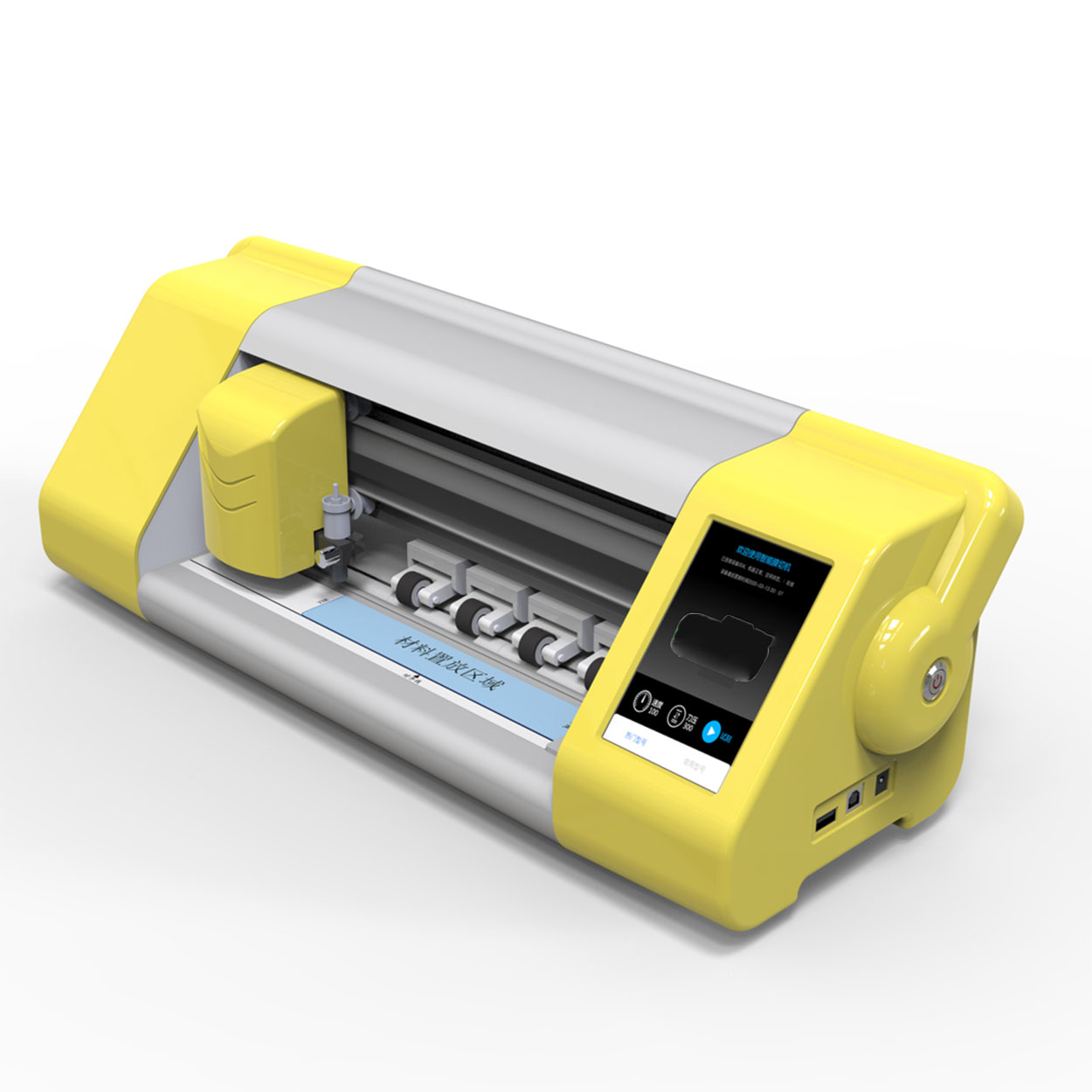

Quale macchina per il taglio dei film e quale applicazione

Le macchine per il taglio di pellicole hanno svolto un ruolo cruciale nell'evoluzione del cinema e di vari processi industriali, consentendo di tagliare e giuntare con precisione i materiali in pellicola.

Che cos'è una macchina da taglio per protezioni dello schermo?

Una macchina per il taglio di protezioni dello schermo è un dispositivo specializzato progettato per produrre protezioni dello schermo su misura per vari dispositivi elettronici, tra cui smartphone, tablet, smartwatch, laptop e monitor.

Come funziona la tagliatrice del protettore dello schermo del telefono cellulare?

La macchina per il taglio delle protezioni dello schermo del telefono cellulare è un dispositivo sofisticato progettato

per produrre protezioni per lo schermo personalizzate per vari dispositivi digitali con un'elevata qualità.

e l'efficienza.

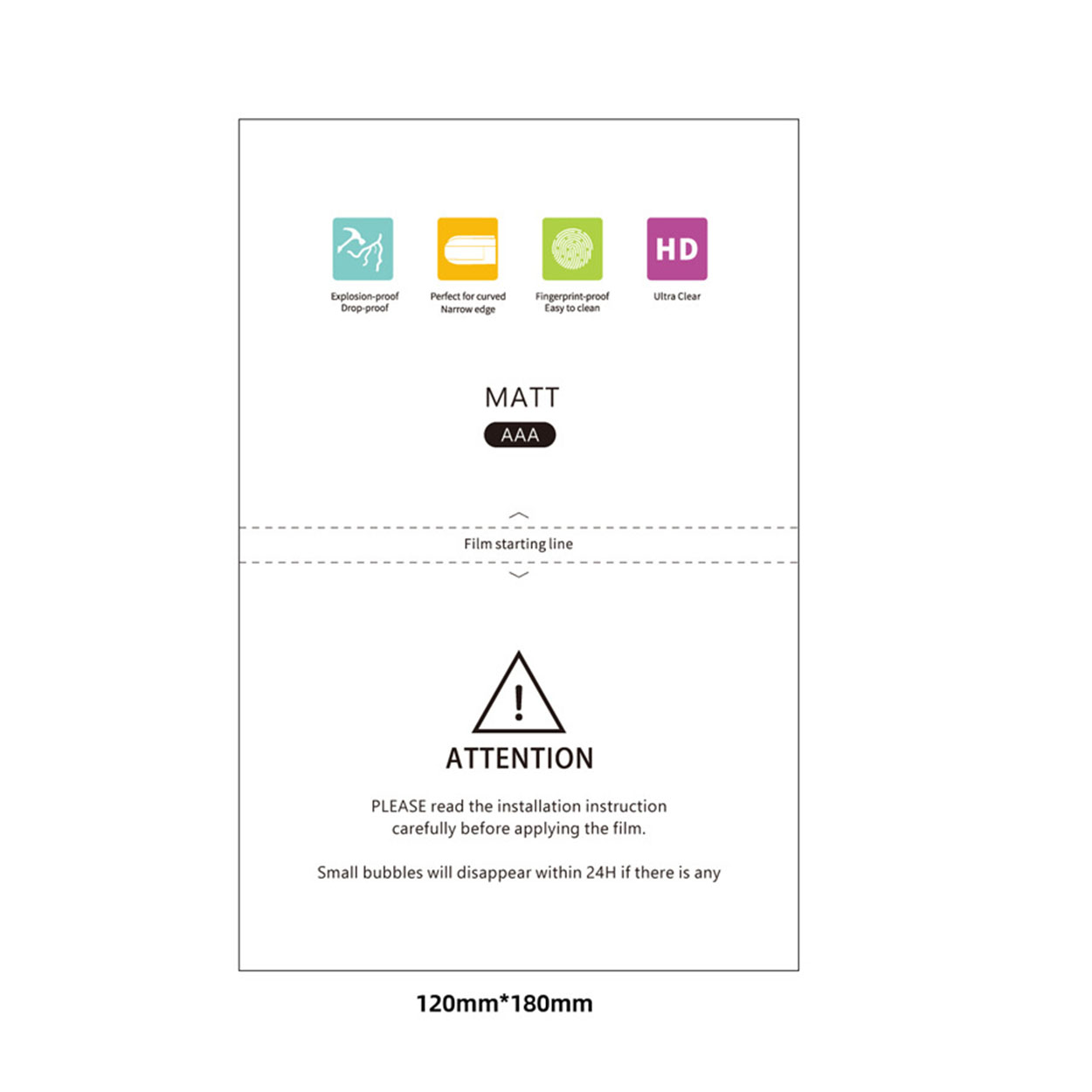

Caratteristiche del vetro temperato del telefono cellulare e della protezione dello schermo TPU del telefono cellulare

Le protezioni per lo schermo in poliuretano termoplastico (TPU) sono flessibili, resistenti e

pellicole di plastica autorigeneranti progettate per proteggere gli schermi dei dispositivi elettronici da

graffi, urti e altri potenziali danni.

Rivoluzionare la protezione dei dispositivi con la macchina per il taglio delle protezioni dello schermo

Che si tratti di uno smartphone, di un tablet o di uno smartwatch, questa versatile macchina è in grado di accogliere una vasta gamma di dispositivi. Si adatta perfettamente alle dimensioni del vostro gadget, offrendo una vestibilità personalizzata che le protezioni generiche non possono eguagliare.

Protezione dello schermo con garanzia a vita

La garanzia a vita di una protezione per lo schermo è una garanzia fornita dai produttori che

promette di riparare o sostituire una protezione per lo schermo per tutta la durata del prodotto, in base a termini e condizioni specifici.