Unlock Efficiency and Profit with Precision Cut Screen Protectors

Stop struggling with outdated pre-cut screen protectors! This precision cutting machine system allows you to create custom-fit screen protectors for any mobile phone on demand. This means no more wasted inventory, no more lost sales due to missing models, and no more frustrated customers with imperfect fits. Investing in a high-quality hydrogel film and cutting machine solution is investing in the future of your business. It’s the ultimate way to ensure perfect protection for every customer, every time.

Precision Cut Screen Protectors: A Revolution in Mobile Protection

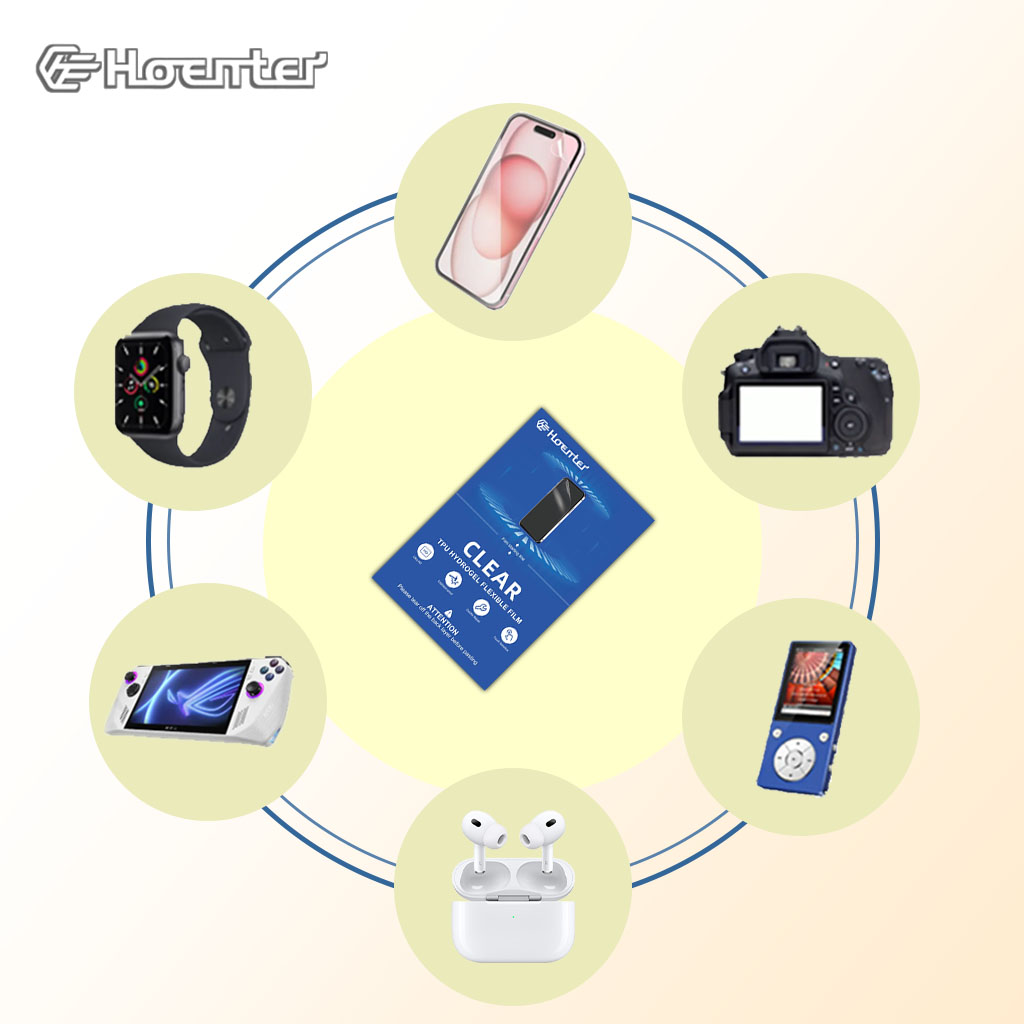

The mobile accessories market is constantly evolving, and pre-cut screen protectors are rapidly becoming obsolete. With precision cut technology, you can offer a superior solution that meets the demands of today’s customers. This system uses rolls of high-quality screen protector film (like TPU or EPU) and a cutting machine to create a perfect protector for any device, instantly.

This precision approach eliminates the need to stock hundreds of different screen protector models, freeing up valuable storage space and capital. It also allows you to say “yes” to every customer, regardless of their device, maximizing sales opportunities. The mobile phone market is incredibly diverse, and this is the only way to truly keep up.

Essential Cutting Tools: The Key to On-Demand Customization

The heart of this system is the cutting machine itself. These machines are sophisticated pieces of equipment, utilizing advanced software and high precision cutting blades to create protectors with unparalleled accuracy. The software database is constantly updated with new device models, ensuring you’re always prepared.

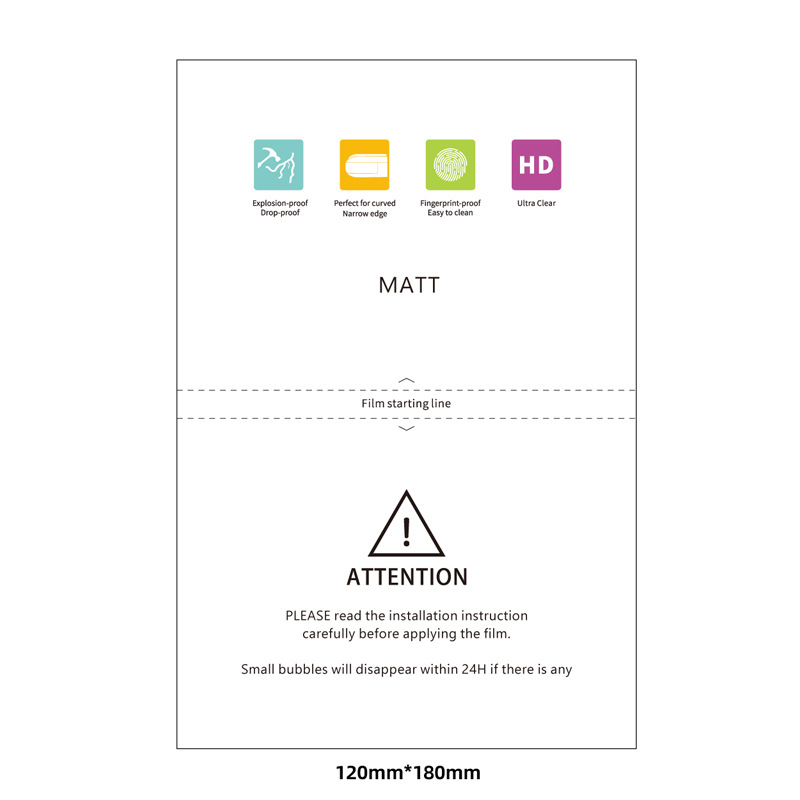

Beyond the machine, you’ll need high-quality film. This could be clear TPU, matte EPU, privacy film, or other specialized materials. The tool itself is designed for ease of use, with intuitive interfaces and automated processes. Think of it as a high-tech stove for screen protectors – you input the ingredients (film and device model), and it outputs a perfectly cooked (cut) protector.

High-Precision Work: Achieving the Perfect Fit Every Time

The accuracy of the cut is paramount. A poorly fitting screen protector is not only unsightly but can also compromise protection and touch sensitivity. Precision cutting machines use laser guidance and advanced algorithms to ensure a flawless fit, every single time. This eliminates the common problems associated with pre-cut protectors, such as gaps, overlaps, and interference with cases.

This level of precision work translates to happier customers, fewer returns, and a more professional image for your business. The cutting tools within the machine are designed for long-lasting performance, ensuring consistent results over thousands of cuts. The precise nature of the cut also makes installation easier, minimizing the risk of bubbles or misalignment.

Beyond the Cut: Additional Tools and Materials

While the cutting machine and film are the core components, other tools and materials can enhance the process and the final result. These might include:

- Application tools: Squeegees, microfiber cloths, and alignment tools for a bubble-free installation.

- Cleaning solutions: Specialized cleaning solutions to prepare the screen before protector application.

- Packaging materials: Custom packaging to present the finished protector professionally.

- Gloves: To ensure a clean and dust free application process, using glove is a good choice.

Investing in these additional items can further improve efficiency and customer satisfaction.

Table: Comparing Precision Cutting to Pre-Cut Protectors

| Feature | Precision Cutting System | Pre-Cut Protectors |

|---|

| Inventory | Rolls of film | Hundreds of individual protectors |

| Obsolescence | Never | Constantly |

| Fit | Perfect, custom-fit | Often imperfect |

| Sales Potential | Unlimited | Limited by stock |

| Installation | Easier, more consistent | Can be tricky |

| Customer Satisfaction | Higher | Lower |

| Profit Margins | Higher | Lower |

Conclusion (10 Key Takeaways):

- Universal Compatibility: Fits any device with a cutting machine.

- On-Demand Customization: Create perfect-fit protectors instantly.

- Superior Precision: Laser-guided cutting for flawless accuracy.

- High-Quality Materials: Use premium films like TPU or EPU.

- Easy Installation: Minimize bubbles and misalignment.

- Reduced Inventory Costs: No need to stock countless pre-cut models.

- Eliminates Waste: Cut only what you need, minimizing obsolete stock.

- Increased Profit Margins: Offer a premium, custom-fit service.

- Improved Customer Satisfaction: Perfect fit and easy application lead to happier customers.

- Future-Proof Solution: Adapts to new device releases instantly.

By embracing precision cutting, your business can revolutionize its screen protector offering, delivering superior customer service and maximizing profitability. The precision and control offered by this system are unmatched.