Customizing Flexible Hydrogel Films for Unique Device Shapes

Table of Contents

Extract

Summary

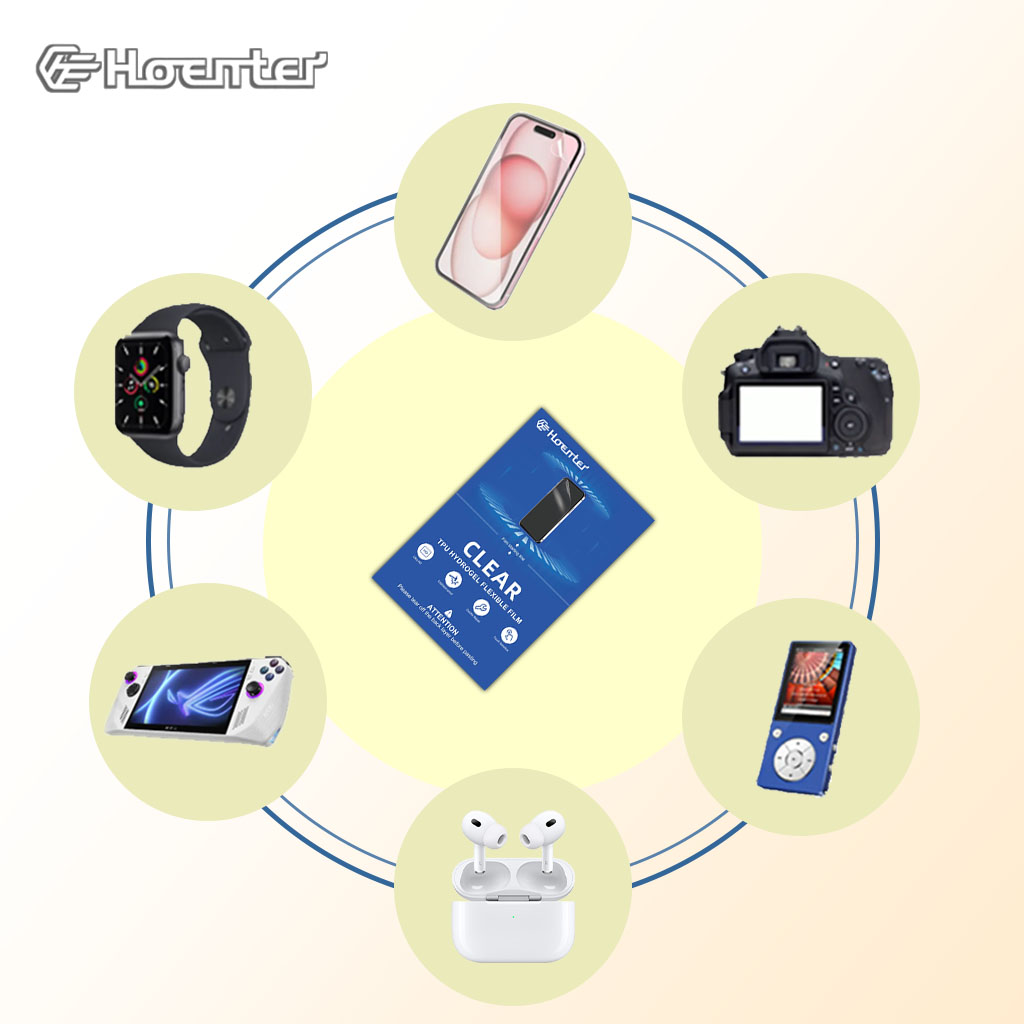

The proliferation of diverse and innovative device designs, from smartphones to wearables, has created a growing need for screen protectors that can adapt to various shapes and contours. Flexible hydrogel films have emerged as a versatile solution in this context, offering a high degree of customization to fit unique device shapes. This article explores the process and benefits of customizing flexible hydrogel films for different devices, addressing the technical challenges and practical considerations involved.

Understanding Flexible Hydrogel Films

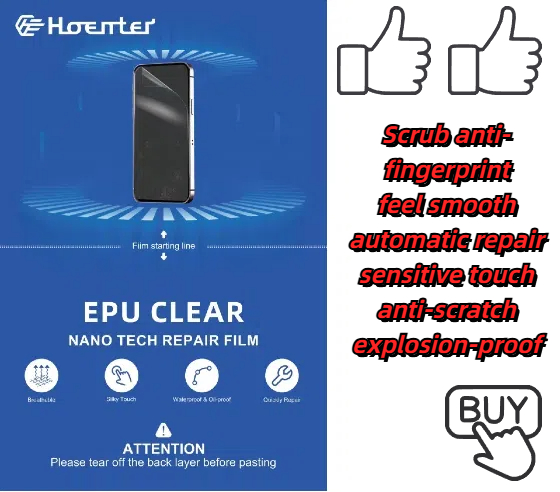

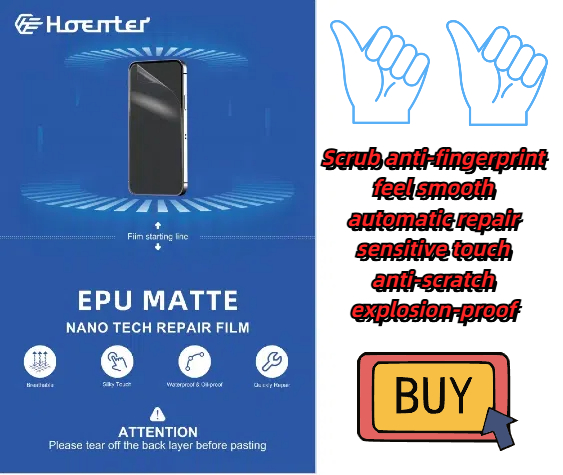

Flexible hydrogel films are made from a polymer network that is soft and pliable, allowing the material to conform to the contours of any surface. Unlike traditional screen protectors made from glass or rigid plastics, hydrogel films can stretch and adapt to irregular shapes, making them ideal for modern devices with non-standard screen designs. The material’s inherent flexibility and self-healing properties add to its appeal, providing protection that is both durable and aesthetically pleasing.

The Customization Process

1. Designing the Film: The first step in customizing flexible hydrogel films is designing the film to match the specific dimensions and contours of the device. This involves creating a digital template of the device’s screen, which includes measurements of its width, height, and any curves or edges. Advanced software and 3D modeling tools are often used to generate an accurate template that will guide the cutting and application of the hydrogel film.

2. Cutting and Shaping: Once the design is finalized, the hydrogel film is cut to match the device’s dimensions. This is typically done using precision cutting machines or laser cutters that ensure a perfect fit. For devices with complex shapes, such as curved screens or multi-dimensional surfaces, the cutting process may involve multiple stages to achieve the desired fit. The hydrogel film’s flexibility allows it to be molded and adjusted during application, ensuring that it adheres seamlessly to the device.

3. Application and Adjustment: Applying a customized hydrogel film requires careful handling to ensure a smooth and bubble-free installation. The film is typically equipped with a self-adhesive backing that allows it to stick to the screen without the need for additional adhesives. During application, users can adjust the film to align it precisely with the device’s edges and contours. The flexibility of the hydrogel material makes it easier to reposition and smooth out any wrinkles or air bubbles.

4. Post-Application Care: After the film is applied, it is essential to follow proper care instructions to ensure the best performance. This may include allowing the film to settle for a specific period, avoiding exposure to harsh chemicals or abrasive materials, and regularly cleaning the surface with appropriate cleaners. Proper care helps maintain the film’s appearance and functionality, ensuring long-lasting protection for the device.

Benefits of Customizing Flexible Hydrogel Films

1. Perfect Fit for Unique Shapes: One of the primary advantages of customizing hydrogel films is the ability to achieve a perfect fit for devices with unique shapes. Whether the device features a curved screen, a notch, or an irregular design, hydrogel films can be tailored to match the exact dimensions and contours. This customization ensures comprehensive protection without gaps or exposed areas.

2. Enhanced Aesthetics: Customized hydrogel films provide a seamless and unobtrusive layer of protection that enhances the device’s overall aesthetics. Unlike traditional protectors, which may add bulk or interfere with the device’s design, hydrogel films conform to the device’s surface, preserving its sleek and modern appearance. This is particularly important for high-end devices where design and visual appeal are crucial.

3. Improved Functionality: Flexible hydrogel films maintain the device’s touch sensitivity and screen clarity, ensuring that the user experience is not compromised. The material’s thin profile and optical clarity mean that the screen’s brightness, color accuracy, and responsiveness are preserved. Customized hydrogel films ensure that these qualities are maintained, regardless of the device’s shape.

4. Self-Healing Properties: The self-healing nature of hydrogel films is an added benefit, particularly for devices that are frequently used or exposed to potential damage. Minor scratches and dents on the film can heal over time, maintaining a clean and clear screen. This property is especially valuable for devices with complex shapes, where traditional protectors may be more prone to damage.

Challenges and Considerations

1. Complexity of Device Designs: Customizing hydrogel films for devices with highly complex or irregular shapes can be challenging. The accuracy of the cutting and application process is crucial to ensure a perfect fit. Advanced technology and skilled technicians are often required to handle intricate designs and achieve the desired results.

2. Cost Implications: Customized hydrogel films may be more expensive than standard protectors due to the additional design, cutting, and application processes involved. For manufacturers and consumers, the cost must be weighed against the benefits of a tailored fit and enhanced protection.

3. Availability and Accessibility: While the technology for customizing hydrogel films is advancing, it may not be widely available for all types of devices. Manufacturers and suppliers need to invest in specialized equipment and expertise to offer customized solutions. Consumers may need to seek out specific providers that offer these tailored products.

Future Trends in Customization

1. Advanced Cutting Technology: As technology continues to evolve, we can expect advancements in cutting and shaping techniques for hydrogel films. Laser cutting and precision machinery will become more refined, allowing for even greater accuracy and customization for a broader range of devices.

2. Integration with Device Designs: Future developments may involve closer collaboration between device manufacturers and screen protector producers. By integrating customization processes with device design workflows, manufacturers can create more seamless and efficient solutions for protecting unique device shapes.

3. Eco-Friendly Materials: Sustainability will likely play a significant role in the future of hydrogel film customization. The development of biodegradable and environmentally friendly hydrogel materials will enhance the overall sustainability of customized screen protectors, aligning with growing consumer demands for eco-friendly products.

Conclusion

Customizing flexible hydrogel films for unique device shapes offers numerous benefits, including a perfect fit, enhanced aesthetics, and improved functionality. While there are challenges related to complexity, cost, and availability, the advantages of tailored protection make hydrogel films a valuable choice for modern devices. As technology advances and sustainability considerations become more prominent, the future of customized hydrogel films promises even greater possibilities for protecting a diverse range of devices while meeting the needs of both consumers and manufacturers.

Comments

Hydrogel Film Privacy Screen Protector

The screen protector offers 30° true privacy with advanced louver encryption, ensuring secure usage in public spaces while maintaining a clear front view for the user. Made from optical-grade TPU, it preserves pristine display quality and supports seamless device unlocking, compatible with both 3D curved and flat screens. Utilizing AG etching technology, it eliminates diagonal lines and ghosting, reducing eye strain. The protector is easy to apply and remove, leaving no residue behind.

Budget-Friendly Phone Screen Protector Machines: Top Picks

In the competitive landscape of mobile accessories, offering high-quality phone screen protectors can be a lucrative venture.

Best Mobile Phone Screen Protector Cutting Machine

Discover the future of mobile protection with our guide to screen protector cutting machines. Learn how film cutters create custom screen protectors

How to Fix a Screen Protector with Bubbles?

By following these tips, you can enjoy a smooth, bubble-free screen protector that keeps your phone looking and functioning its best.

Is Tpu Screen Protector Shock Resistant?

The are pivotal in determining the durability, functionality, and user experience of

modern mobile devices.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.