Revolutionize Your Business with a Hydrogel Film Screen Protector Cutting Machine

This article explores the incredible benefits of investing in a hydrogel film screen protector cutting machine for businesses that deal with mobile phone accessories, especially phone screen protectors. We’ll dive deep into how this innovative technology can streamline your operations, boost customer satisfaction, and ultimately increase your profits. If you’re in the business of selling or applying Skærmbeskyttelse, or if you’re looking for ways to optimize your inventory and offer custom solutions, this article is your ultimate guide. You will learn not only about the machine itself, but also about different types of screen, their advantages and disadvantages, what a film cutter is, and how to start a screen protector business.

What is a Screen Protector Cutting Machine and Why Do You Need One?

A Skæremaskine til skærmbeskyttelse is a sophisticated device designed to precisely cut screen protector film into the exact shape and size required for various mobile phone models and other electronic devices. It utilizes advanced cutting technology to create custom-fit Skærmbeskyttelse on demand. These machines have become indispensable for phone accessory retailers, repair shops, and wholesalers because they eliminate the need to stock a large inventory of pre-cut Skærmbeskyttelse for every possible Telefonmodel. Our screen protector machine is designed to be user-friendly, efficient, and versatile.

Investing in a Skæremaskine til skærmbeskyttelse offers numerous advantages. Firstly, it drastically reduces inventory costs by allowing you to produce Skærmbeskyttelse as needed, rather than stocking a wide range of pre-cut options. Secondly, it enables you to offer custom-fit Skærmbeskyttelse for any mobile phone screen, even the latest or less common models, giving you a competitive edge. Finally, it enhances customer satisfaction by providing perfectly fitted Skærmbeskyttelse and the option for personalized designs, such as custom back film patterns. You can use it not only for mobile phone front protection but also on the back. It’s very suitable for mobile phone stores or phone repair shops. For example, our film screen protector cutting machine is a great choice.

What Are the Advantages of a Screen Protector Made by a Film Cutting Machine?

Skærmbeskyttelse made by a Filmskæremaskine offer several key advantages of screen protector products. The precision of the cutting process ensures a perfect fit on the mobile phone screen, covering every curve and edge without interfering with the device’s functionality or aesthetics. This precise fit is crucial for providing optimal Skærmbeskyttelse against scratches, impacts, and daily wear and tear. Also, a precise fit is important for protector application.

Another significant advantage is the variety of materials that can be used. Film cutting machines can handle different types of screen protector film, including hydrogel-film, TPU, and even specialized options like matte film eller glass film. Hydrogel-film, in particular, is gaining popularity due to its self-healing properties, flexibility, and ability to provide edge-to-edge coverage on curved screens. The machine can cut not only hydrogel but also other materials. Our Skæremaskine til skærmbeskyttelse can help you with that.

How Does a Hydrogel Film Cutting Machine Work?

A hydrogel film skæremaskine operates using a combination of advanced software and precision cutting tool. The machine is designed to be user-friendly. First, the user selects the specific Telefonmodel and the desired type of Skærmbeskyttelse from a digital database. This database is regularly updated to include the latest mobile phone models, ensuring you can always cater to your customers’ needs. The machine is designed to update its database automatically.

Once the model and material are selected, the hydrogel-film (or other chosen cutting material) is loaded into the machine. The cutting parameters are set, either automatically or manually, depending on the protector material. The machine then uses its precision cutting blades to accurately cut the screen protector film to the exact dimensions required. The entire cutting process is quick and efficient, typically taking only a few seconds. The machine uses different cutting parameters for different materials. The machine allows for the creation of screen protector custom designs. The machine and cutting process are made to be efficient. It’s a small machine, so it won’t take up much space, but it will provide great screen cutting quality.

What Types of Screen Protectors Can Be Made with a Screen Protector Machine?

One of the greatest strengths of a Skærmbeskyttelsesmaskine is its versatility. It can create a wide range of Skærmbeskyttelse to suit different customer preferences and device requirements. The most popular type is the hydrogel screen protector, known for its flexibility, self-healing properties, and ability to conform to curved screens.

Beyond hydrogel, these machines can also cut protector film made from TPU, PET, and other materials. This allows you to offer a diverse product range, including ultra-clear Skærmbeskyttelse for maximum transparency, matte film to reduce glare, and even specialized options like privacy filters or blue light filters. Furthermore, many machines, including our intelligent filmskæremaskine, support the creation of custom back film designs, allowing customers to personalize their devices with unique patterns, colors, or even images using a heat transfer machine. This provides your film for phone with customer customized.fast customized screen and back protection film.

Is a Film Cutter Different from a Screen Protector Cutting Machine?

While the terms “film cutter” and “Skæremaskine til skærmbeskyttelse” are often used interchangeably, there can be subtle differences. A film cutter generally refers to a broader category of machines that can cut various types of thin film materials, not limited to Skærmbeskyttelse. These might include vinyl for decals, window tinting film, or other adhesive-backed materials. It can be also known as screen protector plotter.

A Skæremaskine til skærmbeskyttelse, on the other hand, is specifically designed for cutting screen protector film for electronic devices. While it technically is a type of film cutter, it’s optimized for the specific materials and precision required for Skærmbeskyttelse. These machines typically have features tailored for this purpose, such as a comprehensive database of device templates, automatic film feeding, and settings optimized for different types of Skærmbeskyttelse materials, especially hydrogel film cutting. The intelligent screen protector cutter is made for precise work. You can use intelligent film with it.

Why is Hydrogel the Preferred Material for Modern Screen Protectors?

Hydrogel has emerged as a highly favored material for Skærmbeskyttelse, particularly with the rise of curved-edge displays on smartphones. Hydrogel is a type of soft, flexible polymer that has the ability to absorb impacts and even self-heal minor scratches. This makes it an excellent choice for mobile device protection. Hydrogel cutting is very popular.

Hydrogel skærmbeskyttere offer several advantages over traditional Skærmbeskyttelse af glas options. They are more flexible, allowing them to conform perfectly to curved mobile phone screen edges, providing full coverage without lifting or peeling. This flexibility also makes them more resistant to cracking or shattering upon impact. Additionally, hydrogel-film often has self-healing properties, meaning minor scratches and scuffs will disappear over time, keeping the Skærmbeskyttelse looking pristine. Also, the hydrogel provides a great film application.

How to Start a Screen Protector Making Business with a Cutting Machine?

Starting a screen protector making business using a Skæremaskine til skærmbeskyttelse can be a lucrative venture. The first step is to invest in a high-quality screen protector film cutting machine. Consider factors such as the machine’s cutting precision, material compatibility, template database, ease of use, and after-sales support. As an experienced forward machine factory, we are committed to providing our customers with quality machines.

Once you have your Skæremaskine til skærmbeskyttelse, you’ll need to source screen protector film in bulk rolls. Establish relationships with reliable suppliers who can provide you with high-quality hydrogel-film and other materials. Next, you’ll need to market your services. If you have a physical store, promote your custom Skærmbeskyttelse services to your existing customers. If you operate online, create a website and utilize digital marketing strategies to reach your target audience. You may start your own screen protector business. The machine price will quickly pay off.

What to Look for in a Film Screen Protector Cutting Machine Series?

Når du vælger en film screen protector cutting machine from a particular machine series, there are several key features to consider. First, evaluate the machine’s cutting precision and speed. Look for a machine that uses high-quality cutting blades and advanced technology to ensure accurate and efficient cut screen protectors. Also, check if the machine has precise cutting. The machine allows for very detailed work.

Another crucial aspect is the machine’s template database. A good Skæremaskine til skærmbeskyttelse should have a comprehensive and regularly updated database that includes templates for a wide range of mobile phone models and other devices. Consider the machine’s material compatibility as well. Ensure it can handle various types of screen protector film, including hydrogel-film, TPU, and other materials you plan to offer. Finally, look for a machine that offers reliable customer support, training, and a warranty, as these can be invaluable, especially when starting out. Our smart screen protector cutting machine has everything listed above.

Can I Create Custom Back Film with a Phone Screen Protector Cutting Machine?

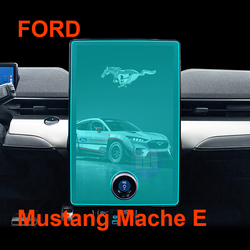

Yes, many modern Skæremaskine til beskyttelse af telefonskærme models, including our mini yellow phone hydrogel cutting machine, are capable of creating custom back film designs. This feature allows you to offer personalized phone skins to your customers, significantly expanding your product offerings and catering to the growing demand for device customization.

To create custom back film, den Skæremaskine til skærmbeskyttelse uses the same precision cutting technology as it does for front film. The primary difference lies in the design and material used. You can use specialized design software to create or import custom patterns, images, or logos. These designs are then transferred to the cutting machine. The rear film can be cut from various materials, including colored or textured vinyl, hydrogel-film with printed designs, or even materials that mimic the look and feel of leather or other premium finishes. You can use the film for phone with customer preferences in mind. Provide your phone with customer customized.fast customized screen beskyttelse.

What is the Future of Screen Protector Technology?

The future of Skærmbeskyttelse technology is bright and full of innovation. As mobile device displays continue to evolve, with foldable phones and other new form factors becoming more prevalent, Skærmbeskyttelse will need to adapt. We can expect to see even more advanced materials, such as improved hydrogel-film with enhanced self-healing properties or new hybrid materials that combine the best qualities of glass og film. Our Skæremaskine til skærmbeskyttelse will keep up with all the innovations.

Smart screen protector cutting technology will also play a crucial role. Future Skæremaskine til skærmbeskyttelse models will likely incorporate more intelligent features, such as AI-powered design tools, even more precise cutting mechanisms, and seamless integration with other devices and systems. The goal will be to make the screen protector making process even faster, more efficient, and more customizable, catering to the ever-growing demand for personalized mobile device protection.

De vigtigste pointer

- A Skæremaskine til skærmbeskyttelse is a valuable investment for businesses dealing with mobile phone accessories, enabling on-demand production of custom-fit Skærmbeskyttelse.

- Hydrogel-film is a preferred material for modern Skærmbeskyttelse due to its flexibility, self-healing properties, and ability to conform to curved screens.

- Film cutting machines offer numerous advantages, including reduced inventory costs, the ability to cater to a wide range of phone models, and enhanced customer satisfaction through personalized options.

- Når du vælger en Skæremaskine til skærmbeskyttelse, consider factors such as cutting precision, material compatibility, template database, ease of use, and after-sales support.

- Many Skæremaskiner til skærmbeskyttelse can also create custom back film designs, allowing you to offer personalized phone case og phone skins to your customers.

- The future of Skærmbeskyttelse technology will likely involve even more advanced materials, smart screen protector cutting features, and seamless integration with other devices.

By embracing the power of a Skæremaskine til skærmbeskyttelse, your business can stay ahead of the curve in the dynamic world of mobile accessories, providing top-notch Skærmbeskyttelse and customized solutions that will delight your customers and drive your success.