Hvad er TPU-materiale?

Indholdsfortegnelse

Sammenfatning

- TPU is a versatile material combining the properties of rubber and plastic.

- It is created through a polyaddition reaction involving diisocyanates and diols.

- TPU is known for its flexibility, strength, and resistance to abrasion and chemicals.

- It is considered safe for use in consumer products, including medical devices.

- TPU filament is popular in 3D printing for creating flexible, durable structures.

- In consumer electronics, TPU is used for protective cases and connectors.

- Compared to other plastics, TPU offers superior durability and performance.

- Injection molding is a common process for manufacturing TPU products.

- TPU’s holdbarhed extends product lifespan and supports sustainability.

- Future trends include expanding applications in automotive, healthcare, and sports industries.

Whether you’re a manufacturer, designer, or consumer, understanding TPU can help you make informed decisions about the materials you use and the products you create.

What is TPU and Why is it Important?

TPU is a versatile material that bridges the gap between rubber and plastic. Its unique properties make it suitable for a wide range of applications, from flexible phone cases to durable industrial components. The importance of TPU lies in its ability to combine flexibility with strength, offering solutions that other materials cannot match. For instance, TPU’s elasticity allows it to absorb shocks and impacts, protecting delicate items like electronics from damage.

How is TPU Made? Understanding the Composition

The production of TPU involves a chemical reaction known as polyaddition, where a diisocyanate reacts with one or more diols. This process creates a polymer with alternating hard and soft segments, giving TPU its distinctive properties. The hard segments provide strength and rigidity, while the soft segments offer flexibility and elasticity. By adjusting the ratio of these segments, manufacturers can tailor TPU to meet specific requirements, such as increased flexibility for wearable devices or enhanced hardness for industrial applications.

What are the Properties of TPU?

TPU’s properties make it a standout material in various industries. Its high tensile strength ensures that products made from TPU can withstand significant stress without breaking. The material’s elasticity allows it to stretch and return to its original shape, making it ideal for applications that require flexibility. Additionally, TPU’s resistance to oil, grease, and abrasion ensures that it maintains its performance even in challenging environments. These properties make TPU a reliable choice for products that need to endure wear and tear over time.

Is TPU Safe for Use?

Safety is a top priority when selecting materials for consumer products, and TPU meets the necessary standards. It is non-toxic and does not release harmful chemicals, making it safe for use in products that come into contact with skin, such as medical devices and wearable technology. TPU’s safety credentials have made it a popular choice in industries where consumer health and safety are paramount.

How is TPU Used in 3D Printing?

TPU filament is a game-changer in the world of 3D printing. Its flexibility and strength allow for the creation of complex structures that can withstand wear and tear. TPU filament is particularly useful for printing items that require elasticity, such as phone cases, shoe soles, and flexible joints. The ability to print with TPU opens up new possibilities for designers and engineers, enabling them to create innovative products that were previously difficult to manufacture.

What are the Applications of TPU in Consumer Electronics?

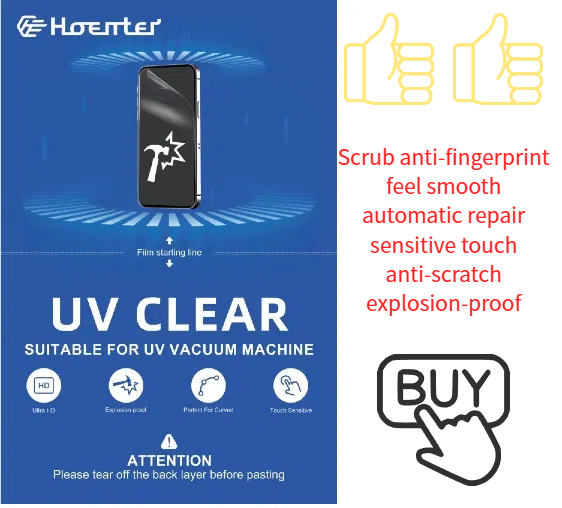

In the consumer electronics industry, TPU is used for protective cases, cables, and connectors. Its ability to absorb impact and resist abrasion makes it ideal for protecting delicate electronic components. TPU’s flexibility also allows for innovative designs that enhance the functionality and aesthetics of electronic devices. For example, TPU cases can provide a secure grip and shock absorption, protecting smartphones from accidental drops.

How Does TPU Compare to Other Plastics?

Compared to other plastics, TPU offers a unique combination of flexibility and strength. While materials like TPE (Thermoplastic Elastomer) share some similarities with TPU, TPU’s superior abrasion resistance and durability set it apart. This makes TPU a preferred choice for applications that demand high performance and longevity. For instance, TPU’s resistance to wear and tear makes it ideal for products that are subject to frequent use, such as sports equipment and footwear.

What is the Role of TPU in Injection Molding?

Injection molding is a common manufacturing process for TPU, allowing for the mass production of complex shapes with high precision. TPU’s melt-processable nature makes it ideal for injection molding, enabling the creation of products with intricate designs and consistent quality. This process is widely used in industries such as automotive and consumer electronics, where precision and efficiency are critical.

How Does TPU Enhance Durability in Products?

The durability of TPU is one of its standout features. Products made with TPU can withstand harsh conditions, including exposure to chemicals, UV light, and extreme temperatures. This durability extends the lifespan of products, reducing the need for frequent replacements and contributing to sustainability. For example, TPU’s resistance to UV light makes it suitable for outdoor applications, where exposure to sunlight can degrade other materials.

What are the Future Trends in TPU Applications?

As technology advances, the applications of TPU continue to expand. Innovations in TPU processing and formulation are leading to new uses in industries such as automotive, healthcare, and sports equipment. The versatility and adaptability of TPU make it a material with significant potential for future developments. For instance, TPU’s ability to be recycled and reused aligns with the growing demand for sustainable materials, making it an attractive option for environmentally conscious manufacturers.

Kommentarer

Tags

Sådan fjerner du Invisible Shield Screen Protector?

By following these steps, you can confidently remove and replace your Zagg InvisibleShield screen protector, ensuring your device stays protected and looking its best!

Sådan vælger du den bedste skærmbeskyttelsesfabrik til din virksomhed

At vælge den rigtige fabrik til skærmbeskyttelse er afgørende for din virksomhed og kan have stor indflydelse på produktkvaliteten, kundetilfredsheden og den samlede rentabilitet.

Er Hydrogel skærmbeskytter bedre end hærdet glas?

Valget mellem skærmbeskyttere med hydrogel og hærdet glas afhænger af dine prioriteter.

Fordelene ved fleksible hydrogel-film til bærbare enheder

Fleksible hydrogel-film har vist sig at være et banebrydende materiale til bærbare enheder, der tilbyder en unik blanding af biokompatibilitet, mekanisk fleksibilitet og reaktionsevne over for miljømæssige stimuli.

Skærmbeskyttelsesskæremaskine Pris vs. ydeevne - find den rette balance

Emnet "Pris vs. ydeevne for skæreskæringsmaskiner til skærmbeskyttelse" udforsker den kritiske balance mellem omkostninger og funktionalitet for maskiner, der bruges til at skære skærmbeskyttelse.

Find al viden og alle trends på vores blog, få engrosprisen og den bedste kvalitet fra vores fabrik.

Hvilken filmskæremaskine og dens anvendelse

Filmskæremaskiner har spillet en afgørende rolle i udviklingen af filmproduktion og forskellige industrielle processer ved at muliggøre præcis skæring og splejsning af filmmaterialer.

Hvad er en skæremaskine til skærmbeskyttelse?

En skæremaskine til skærmbeskyttelse er en specialiseret enhed, der er designet til at producere skræddersyede skærmbeskyttere til forskellige elektroniske enheder, herunder smartphones, tablets, smartwatches, bærbare computere og skærme.

Hvordan skæremaskine til skærmbeskyttelse af mobiltelefoner fungerer?

En maskine til at skære skærmbeskyttelse til mobiltelefoner er en sofistikeret enhed designet

at producere skræddersyede skærmbeskyttere til forskellige digitale enheder med høj præci

sion og effektivitet.

Karakteristika for hærdet glas til mobiltelefoner og TPU-skærmbeskyttelse til mobiltelefoner

Skærmbeskyttere af termoplastisk polyuretan (TPU) er fleksible, holdbare og

selvhelende plastfilm designet til at beskytte elektroniske enheders skærme mod

ridser, slag og andre potentielle skader.

Revolutioner beskyttelsen af enheder med en skæremaskine

Uanset om du har en smartphone, en tablet eller et smartwatch, kan denne alsidige maskine rumme en lang række enheder. Den tilpasser sig problemfrit til dimensionerne på din gadget og giver en tilpasset pasform, som generiske beskyttere ikke kan matche.

Livstidsgaranti på skærmbeskyttelse

En livstidsgaranti på skærmbeskyttelse er en garanti fra producenterne, der

lover at reparere eller udskifte en skærmbeskytter i hele produktets levetid på særlige vilkår.