Environmental Benefits of Using a Screen Protector Cutter: Reduce Waste

Table of Contents

Extract

Summary

The topic of the page: Environmental Benefits of Using a Screen Protector Cutter-Reduce Waste The draft page:

Waste Reduction

The concept of waste reduction is fundamental in environmental sustainability, particularly in the context of consumer products such as screen protectors. By focusing on reducing waste before it is created, individuals can significantly impact resource conservation and environmental preservation. A key strategy is source reduction, which involves minimizing waste at its origin, thereby preventing the need for excessive recycling or disposal methods later on

.

Benefits of Waste Reduction

Reducing waste offers several advantages, including the conservation of natural resources, reduction of greenhouse gas emissions, and cost savings. The manufacturing process for traditional screen protectors often entails energy-intensive procedures and the release of harmful emissions. In contrast, eco-friendly screen protectors are produced using energy-efficient methods, which help mitigate these negative environmental impacts

. This shift not only contributes to a smaller carbon footprint but also promotes the sustainable use of materials.

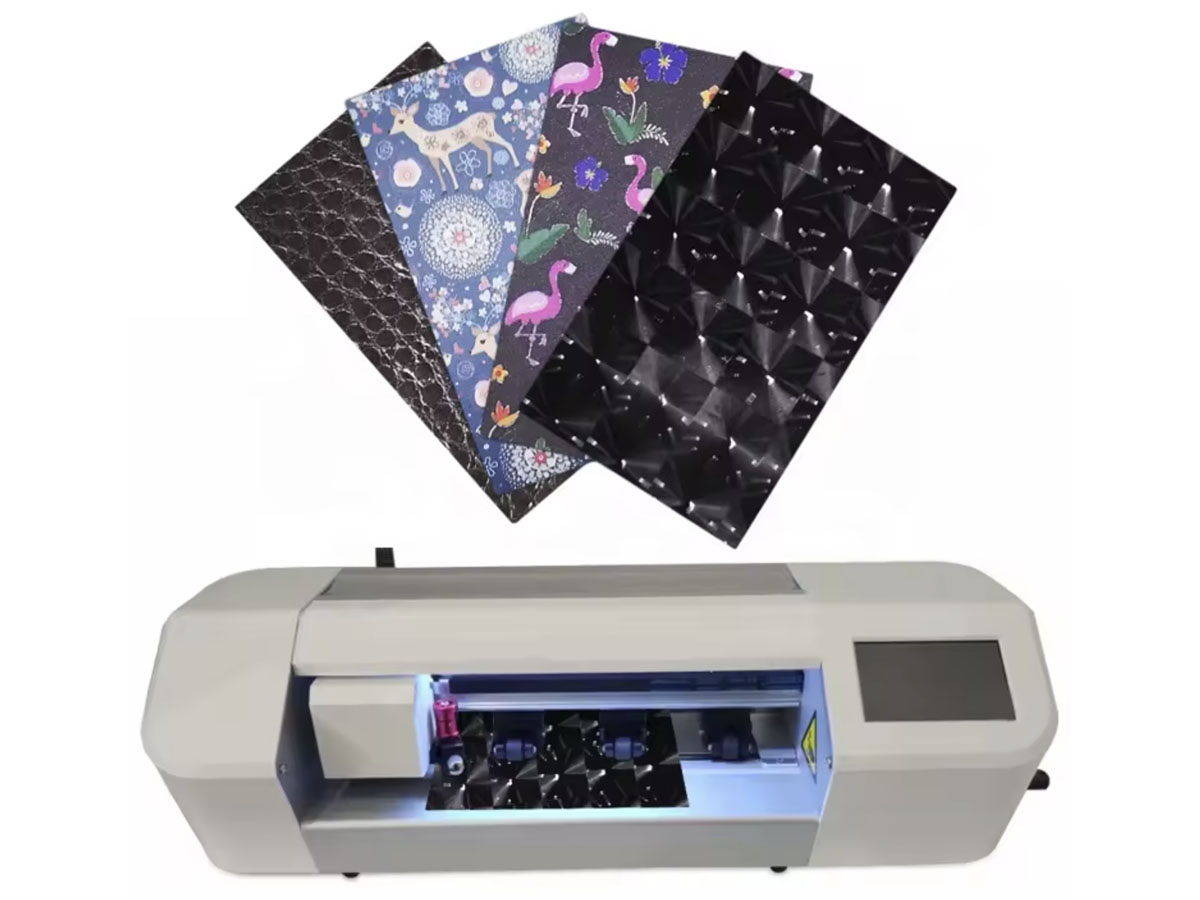

Custom Cut Screen Protectors

One effective approach to waste reduction is the use of custom cut screen protectors. These are specifically tailored to fit individual devices, significantly minimizing material waste associated with standard, one-size-fits-all options. Traditional screen protectors often generate excess waste during installation due to the need for trimming or adjustment. Custom cut options eliminate this inefficiency by providing a perfect fit, which enhances user experience while also safeguarding the device

.

Sustainable Manufacturing Practices

Manufacturers can further support waste reduction by adopting sustainable practices in their production processes. This includes utilizing renewable energy sources, implementing energy-efficient machinery, and optimizing production methods to eliminate material waste

. By transitioning to these eco-friendly practices, companies can not only enhance the sustainability of their products but also contribute positively to the environment by reducing their overall resource consumption.

Material Efficiency

Overview of Material Use

In the design and manufacturing of screen protectors, material efficiency plays a crucial role in minimizing waste and enhancing sustainability. As screen protectors serve to protect devices from damage, the materials selected for their production must balance performance with environmental impact. The most common materials include plastics like PET (Polyethylene Terephthalate) and TPU (Thermoplastic Polyurethane), which are lightweight and can be easily processed to fit various devices

. However, these plastics can take hundreds of years to decompose, raising concerns about their long-term environmental effects.

Advancements in Sustainable Materials

Recent innovations have led to the exploration of sustainable alternatives to traditional plastic-based screen protectors. Materials such as bamboo, cork, and glass have emerged as eco-friendly options due to their biodegradable nature and lower environmental impact

. Furthermore, the introduction of screen protectors made from recycled plastics addresses the problem of resource consumption by reducing the need for new materials, thereby contributing to a circular economy.

Waste Reduction through Efficient Design

Using a screen protector cutter can significantly improve material efficiency by allowing users to customize and fit protectors to their specific devices, reducing leftover material

. This capability not only minimizes waste but also enhances user satisfaction by ensuring a better fit and appearance. Additionally, efficient processing techniques can optimize the use of raw materials, thereby reducing the overall carbon footprint associated with manufacturing.

Impact on the Environment

The traditional production and disposal processes of screen protectors contribute to significant environmental challenges. The constant replacement of protectors generates substantial waste, as most materials are non-biodegradable and contribute to landfill overflow

. By opting for sustainable materials and employing efficient manufacturing processes, both manufacturers and consumers can play a role in reducing this environmental impact, promoting a more sustainable approach to device protection.

Economic Benefits

The economic advantages of utilizing a screen protector cutter extend beyond mere cost savings to encompass broader benefits that positively impact businesses and communities.

Cost Savings for Businesses

Businesses that adopt screen protector cutters can experience significant cost reductions. By reducing reliance on expensive virgin materials, companies can lower their production costs, enhancing their profit margins. Moreover, employing recycling practices related to screen protectors can diminish waste disposal expenses, as less material is directed towards landfills or incineration.

This diversion not only curtails waste management costs but can also lead to tax incentives, further encouraging sustainable practices within businesses.

Job Creation and Economic Stability

The recycling and reuse of materials, including screen protectors, create employment opportunities across various sectors. The recycling industry alone accounts for a considerable number of jobs, contributing to economic stability within communities. In fact, recent studies indicated that recycling activities in the United States generated approximately 681,000 jobs, along with $37.8 billion in wages and $5.5 billion in tax revenues.

This economic ripple effect supports local economies and enhances livelihoods.

Energy Conservation

Utilizing screen protector cutters also aids in energy conservation. The process of recycling materials is significantly less energy-intensive than manufacturing new products from raw materials. By conserving energy, businesses contribute to lower greenhouse gas emissions and mitigate the effects of climate change. For example, recycling just 10 plastic bottles saves enough energy to power a laptop for over 25 hours, underscoring the broader energy-saving potential associated with recycling initiatives.

Enhanced Brand Image and Consumer Demand

In today’s marketplace, consumers are increasingly prioritizing sustainability. Businesses that adopt screen protector cutters and promote recycling are likely to attract environmentally-conscious consumers, potentially leading to a wider customer base. This commitment to sustainability not only boosts brand image but also can offer a competitive edge, as consumers tend to favor companies that demonstrate environmental responsibility.

Case Studies

Custom Cut Screen Protectors in Practice

The shift towards custom cut screen protectors has significant implications for sustainability and waste reduction. One study highlighted the efficiency of custom fit screen protectors over generic options, demonstrating that they minimize material waste during installation. Traditional generic protectors often lead to excess material being discarded, whereas custom solutions are designed specifically for each device, ensuring that every cut is precise and tailored to maximize coverage

. This transition not only reduces waste but also promotes optimal protection for devices.

User Experience and Longevity

In another case study focusing on user satisfaction, it was found that consumers reported higher satisfaction rates when using custom cut screen protectors. This is largely due to their superior fit, which maintains touch sensitivity and clarity, thereby enhancing the overall user experience. Participants noted that these protectors contributed to their devices’ longevity, decreasing the frequency of replacements compared to standard options

. The durability of high-quality materials used in custom protectors further supports this claim, as they are built to withstand scratches and impacts more effectively than their generic counterparts.

Health and Environmental Impacts

Additionally, a public health study investigated the environmental benefits of reducing electronic waste through the adoption of custom cut screen protectors. By providing better fitting and longer-lasting options, the research indicated a potential decrease in the number of screen protectors discarded annually, aligning with broader sustainability goals within the tech industry. The findings suggested that by lowering the volume of electronic waste generated, custom cut screen protectors contribute positively to environmental health and resource conservation

.

Environmental Impact

The use of screen protector cutters can significantly contribute to reducing waste and minimizing environmental degradation. One of the primary benefits of recycling materials used in screen protection is the prevention of pollution, as improper disposal can lead to harmful pollutants being released into the air, soil, and water

. Additionally, by adopting screen protector cutters, consumers can reduce the need for new products, thereby decreasing reliance on raw material extraction, which is energy-intensive and contributes to greenhouse gas emissions.

Economic Considerations

Investing in screen protector cutters not only aids in environmental conservation but also supports economic opportunities within the recycling industry. This sector creates jobs in collection, sorting, processing, and manufacturing, which are lost when materials are not recycled

. By promoting the reuse of materials through screen protector cutters, communities can harness the potential for job growth in the green sector and support a circular economy focused on resource conservation and sustainability.

Energy Conservation

Recycling materials through screen protector cutters saves energy that would otherwise be expended in the extraction, processing, and transportation of new raw materials

. This reduction in energy consumption not only helps lower greenhouse gas emissions but also mitigates the impact of climate change, contributing to a more sustainable future. For instance, recycling is projected to avoid millions of metric tons of carbon emissions, which is comparable to taking millions of cars off the road for a year.

Long-term Benefits

The overall environmental benefits of using screen protector cutters extend beyond immediate waste reduction. By emphasizing practices such as reduction, reuse, and recycling, we can help sustain the environment for future generations and minimize the adverse effects of climate change

. In conclusion, the implementation of screen protector cutters is a practical step toward promoting a healthier planet and fostering economic growth through sustainable practices.

Challenges and Limitations

Material Limitations

The use of polymers in screen protector manufacturing, while advantageous due to their light weight, low cost, and clarity, presents certain challenges. One significant limitation is their susceptibility to property anisotropy, which can affect the performance and reliability of the final product.

Additionally, despite the economic benefits associated with polymeric packaging, there are complexities related to life-cycle issues that require careful consideration as these materials evolve and are implemented.

Adhesive Bonding Issues

Another critical challenge involves the adhesive bonding process, which is sensitive to the surface conditions of the materials being joined. While industrial adhesives have seen success, achieving a strong bond often necessitates meticulous surface preparation.

The lack of a nondestructive quality control method poses further obstacles to broader application in manufacturing, complicating the assurance of product integrity.

Environmental Considerations

As manufacturers strive to reduce waste and improve sustainability, the integration of eco-friendly practices remains a complex undertaking. For instance, while there is a push to minimize the use of packaging materials, companies must also navigate the implications of waste generation associated with the manufacturing process itself.

Moreover, although consumer awareness regarding sustainable practices is rising, translating this awareness into consistent behavior change among consumers poses an ongoing challenge for businesses seeking to promote eco-friendly product offerings.

Economic Viability

For the adoption of adhesives and polymeric materials to be economically attractive, they must offer value that outweighs existing disadvantages. A more comprehensive understanding of material properties, coupled with advancements in processing and durability, is necessary to enhance their economic viability and acceptance in the market.

As industries continue to innovate, striking the right balance between cost-effectiveness and environmental responsibility will remain a crucial consideration in the future of screen protector production and waste management strategies.

Future Perspectives

As the demand for sustainable solutions increases, future work in the field of materials processing is anticipated to be extensive, particularly in developing innovative polymer applications. This transition involves moving from simple phenomenological models to more complex molecular models that can predict intrinsic polymer properties, thereby improving processing and end-use performance behavior.

The integration of advanced computational methods may significantly contribute to the formulation and optimization of materials, including those used in eco-friendly screen protectors. Moreover, the packaging industry is already making strides towards sustainability by adopting smart packaging solutions that align with eco-friendly principles. These innovations can help reduce waste and enhance recyclability, further promoting a circular economy. By employing such technologies, manufacturers of screen protectors could potentially implement smarter, more sustainable packaging and disposal options, minimizing their environmental impact. Consumer behavior is also a crucial factor influencing the future of waste management. With an increasing number of consumers prioritizing sustainability in their purchasing decisions, companies that produce screen protectors may be incentivized to adopt environmentally friendly practices and materials. The shift toward eco-friendly screen protectors made from biodegradable, recyclable, or compostable materials will be pivotal in reducing plastic waste and preserving ecosystems. Finally, the push for sustainable manufacturing techniques, including energy-efficient production processes, is expected to play a significant role in the future of screen protector manufacturing. Embracing renewable energy sources and eco-friendly materials will not only reduce greenhouse gas emissions but also contribute to a greener future for electronic accessories. As consumers become more aware of these options, the market for custom cut screen protectors that minimize material waste and optimize device coverage is likely to grow, further supporting sustainability goals.

Comments

Porsche Panamera 2021 Navigation Display Tempered Glass

Protect your investment with a high-quality Porsche Panamera 2021 Screen Protector. Prevent scratches and damage to your Panamera’s navigation display.

Is a Matte Screen Protector Good for Drawing?

Whether you’re an artist looking for precision or a student aiming for better notes, a matte screen protector could be the perfect addition to your iPad or tablet setup.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Does a Screen Protector Work Well?

Screen protectors offer valuable protection for your smartphone, helping to prevent scratches, cracks, and other damage.

Which Is Better: Tempered Glass or Hydrogel Screen Protector?

Choosing between tempered glass and hydrogel screen protectors depends on your personal needs and lifestyle.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

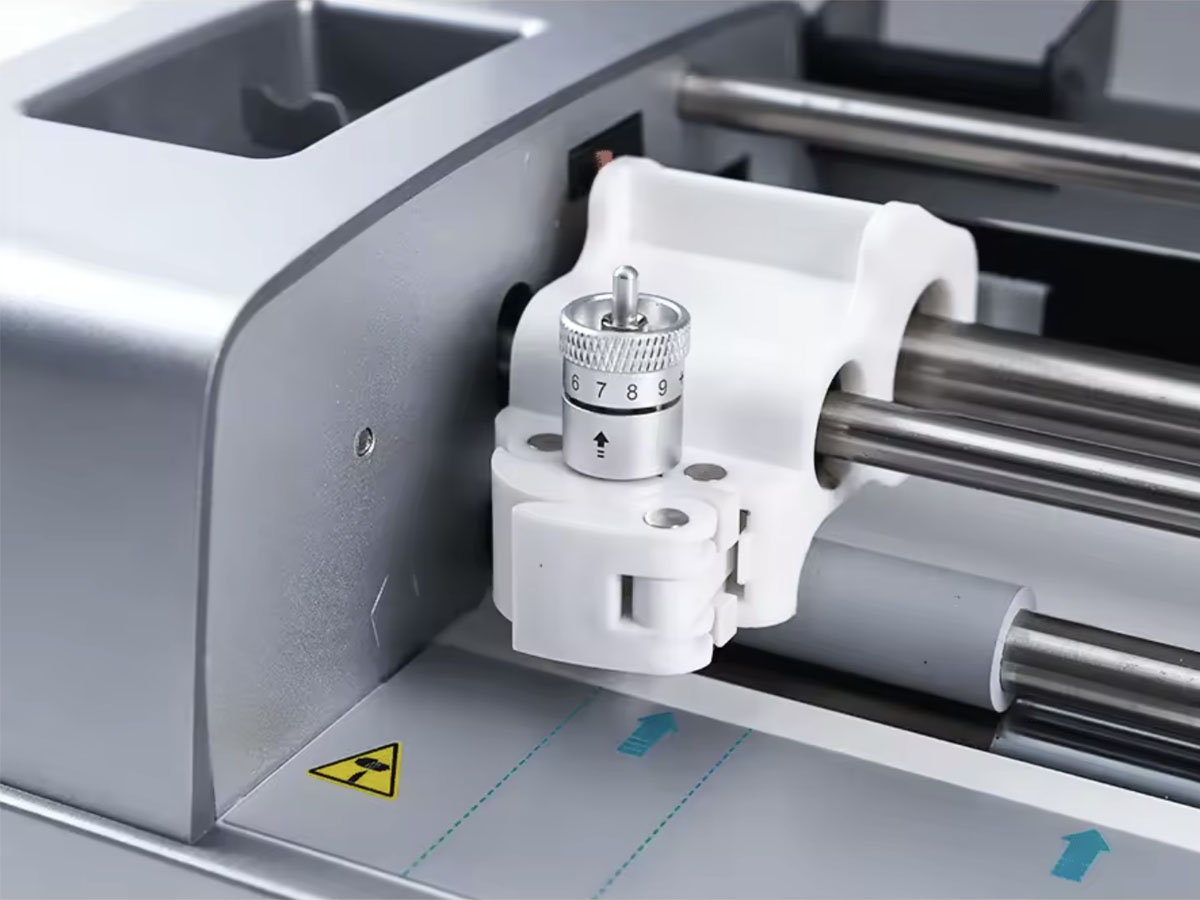

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.