Expert Tips for Maintaining Your Screen Protector Cutter

Table of Contents

Extract

Summary

Lead Section: Expert Tips for Maintaining Your Screen Protector Cutter provides essential guidance on the upkeep of specialized tools designed for the precise application of screen protectors across various devices. These cutters are notable for enhancing device protection by ensuring a seamless fit, thereby preventing scratches, smudges, and accidental damage. The importance of proper maintenance is underscored by the need for efficiency and precision in the cutting process, which can significantly impact the user experience and the longevity of the screen protector. The article elaborates on various types of screen protector cutters, including custom cutters that allow for on-the-spot adjustments and industrial-grade cutters used in bulk applications. Each type serves distinct purposes and caters to different user needs, from individual consumers to professional settings. Common issues that users face, such as cracking and uneven edges, are also discussed, highlighting the critical nature of careful cutting techniques and proper tool handling. Maintenance tips featured in the article emphasize routine inspections, cleaning procedures, and the monitoring of equipment performance to prevent malfunctions and ensure optimal cutting conditions. Additionally, the integration of ergonomic practices is advocated to enhance user comfort and productivity, minimizing the risk of strain or injury during extended use. By addressing these crucial aspects, the article serves as a comprehensive resource for users looking to maximize the effectiveness and durability of their screen protector cutters, ensuring that devices remain well-protected while maintaining touchscreen sensitivity and aesthetic appeal.

Types of Screen Protector Cutters

Screen protector cutters are specialized tools designed to facilitate the precise application of screen protectors on various devices, ensuring a seamless fit and enhanced protection.

Custom Screen Protector Cutters

Custom screen protector cutters, such as those offered by Officeworks, provide an advanced solution for tailoring screen protectors to fit specific devices. Utilizing technologies like ZAGG ISOD, these cutters allow for on-the-spot cutting and application of invisible, purpose-built protection for smartwatches, smartphones, tablets, and laptops. This method ensures edge-to-edge impact and shatter protection, all while maintaining touchscreen sensitivity akin to that of glass.

Manual Alignment Tools

Manual alignment tools help users align screen protectors accurately during application. These tools often come with guides or edges that assist in positioning the protector correctly, minimizing the risk of bubbles and misalignment. Proper preparation and cleaning of the device’s screen before applying the screen protector are essential steps to achieve a successful installation.

Spray Installation Method

Some screen protector installation methods involve the use of a spray solution that moistens the device’s screen and the adhesive side of the protector. This method allows for greater flexibility during application, enabling users to shift the protector into the ideal position without wrinkles or bubbles forming. Although not a cutter per se, this technique is valuable in ensuring a perfect fit and enhancing the overall installation experience.

Industrial-Grade Cutters

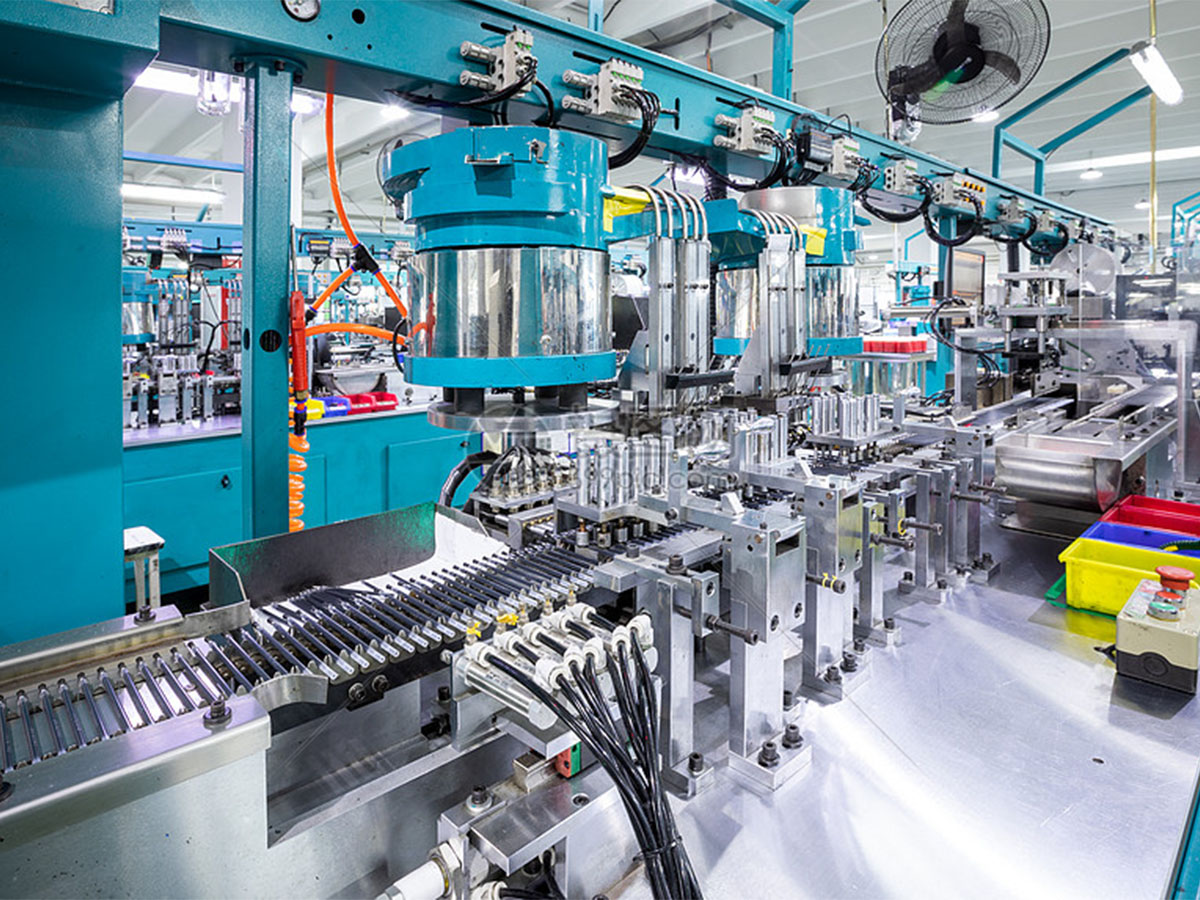

For professional or bulk applications, industrial-grade cutters may be employed. These cutters are designed to handle higher volumes and can cut through various types of materials used for screen protectors, such as tempered glass and plastic film. They are typically used in settings where large quantities of screen protectors need to be cut quickly and accurately, providing durability and efficiency.

Understanding the various types of screen protector cutters can help users choose the right tools for their needs, ensuring that their devices are well-protected from scratches, smudges, and accidental drops.

Common Issues

When using a screen protector cutter, various common issues may arise that can affect the quality of your cuts and the overall effectiveness of the tool. Understanding these issues can help users avoid mistakes and improve their cutting techniques.

Cracking the Screen Protector

One frequent issue is cracking the screen protector during the cutting process. This often occurs due to excessive pressure applied while cutting. It is advisable to cut slowly and gently, ensuring that the blade is not forced through the material, as this could lead to fractures in the glass.

Using a diamond file can help smooth any rough edges post-cutting, but care must be taken to avoid shattering the screen during the initial cuts.

Uneven Edges

Another common problem is achieving uneven edges on the screen protector. This can happen if the cutting motion is not consistent or if the blade is not held at the correct angle. To avoid this, it is crucial to cut materials at a 90-degree angle to maintain a clean edge.

Additionally, using a dremel tool for fine adjustments can help achieve a more precise finish.

Difficulty in Cutting

Users may also experience difficulty in cutting through thicker screen protectors. This can be alleviated by using a tool that is designed for the specific thickness of the material. A diamond file can aid in smoothing cuts, while using water can provide a cushion and make the cutting process easier, thereby reducing the risk of damage to the protector.

Tool Maintenance

Improper maintenance of the cutting tool can lead to issues such as dull blades, which can make cutting ineffective and more hazardous. Regular maintenance, including cleaning reusable blades and following the manufacturer’s safety instructions, is essential for optimal performance.

Users should also ensure that their tools are stored correctly to avoid damage from extreme heat, which can affect the blade’s integrity. By being aware of these common issues and following best practices, users can enhance their experience and ensure better results when cutting screen protectors.

Maintenance Tips

Routine Inspections

Regular inspections of your screen protector cutter are crucial to maintaining its performance. These inspections should include checking for wear and tear on the blades and ensuring that all moving parts are functioning smoothly. Routine maintenance tasks such as cleaning and lubricating the mechanisms can help prevent minor issues from escalating into significant problems

.

Cleaning Procedures

Maintaining a clean workspace is essential for optimal operation. Regularly clean the cutter to remove dust, debris, and any adhesive residue that may accumulate. This can be done using a soft cloth and appropriate cleaning solutions, which will help maintain the integrity of the cutting surface and ensure precise cuts

.

Monitoring Equipment Performance

Monitor the performance of the cutter frequently. This can involve checking the alignment of the blades and ensuring that the cutting pressure is set correctly. By observing these indicators, you can identify potential issues early, which is vital for preventing unexpected breakdowns

.

Documentation of Maintenance Activities

Keeping a detailed log of all maintenance activities is essential. Document each inspection, cleaning, and any repairs made, including dates, actions taken, and any personnel involved. This structured documentation helps track the cutter’s maintenance history and can aid in identifying patterns of wear over time

.

Adaptation to New Technologies

As technology evolves, ensure that your maintenance practices adapt accordingly. Stay updated on new cleaning techniques, replacement parts, and cutting technologies that may enhance the performance of your screen protector cutter. Regularly revising your maintenance plan to include these advancements will improve efficiency and prolong the equipment’s lifespan

.

Feedback and Communication

Foster open communication channels among all users of the cutter. Encourage feedback regarding performance issues or maintenance needs. This collaborative approach ensures that any potential problems are addressed promptly, leading to a more efficient maintenance strategy

. By implementing these maintenance tips, you can ensure that your screen protector cutter operates effectively, reducing downtime and enhancing overall productivity.

Troubleshooting

Troubleshooting is an essential skill for maintaining your screen protector cutter, as it involves identifying and resolving issues that may arise during operation. It is a systematic process that can help you efficiently diagnose problems, ensuring the smooth functioning of your equipment.

General Troubleshooting Techniques

When encountering issues with your screen protector cutter, the first step is to remain calm and avoid panic. Many problems can be addressed using basic troubleshooting techniques. For instance, if the cutter’s screen goes blank or if the device fails to respond, it is important to check the power supply and connections before assuming a more serious malfunction

.

Common Issues and Solutions

Screen or Display Problems

If the display is not functioning, consider the following steps:

- Ensure the cutter is properly connected to a power source.

- Check for any blown fuses or circuit issues.

- Restart the machine after disconnecting and reconnecting it to the power supply.

Cutting Errors

If the screen protector cutter is not cutting correctly, it may be due to misaligned blades or incorrect settings. Verify the blade alignment and adjust the cutting parameters as needed. Regular maintenance checks can help identify wear and tear on the blades, prompting timely replacements to maintain optimal performance

.

Connectivity Issues

In cases where the cutter cannot connect to a computer or software, ensure that the drivers are up to date and that the correct ports are being used. It may be beneficial to reinstall the software if problems persist, as this can often resolve underlying connectivity issues

.

Methodical Approach to Troubleshooting

A structured approach to troubleshooting involves gathering information about the issue, using appropriate tools to diagnose the root cause, and documenting the process. For example, utilizing testing software can help pinpoint technical issues more effectively than trial and error alone

. This method not only enhances the troubleshooting experience but also encourages efficient problem-solving strategies that can be applied to similar issues in the future.

User Ergonomics

Understanding User Ergonomics

User ergonomics focuses on designing and arranging workspaces to align with the capabilities and limitations of users, particularly in tasks involving precision and repeated motions. This is especially important when utilizing tools such as screen protector cutters, which require both dexterity and sustained focus

. By tailoring the workspace to fit the user’s physical and cognitive abilities, ergonomics aims to create an environment that minimizes discomfort and maximizes productivity.

Importance of Ergonomics in Tool Use

Incorporating ergonomic principles in the use of screen protector cutters not only enhances user comfort but also improves efficiency and output quality. A well-designed workspace can significantly reduce the risk of musculoskeletal disorders (MSDs) that may arise from repetitive actions, awkward postures, or prolonged use of non-ergonomic tools

. Thus, investing in ergonomic solutions is beneficial for both the user’s health and the overall performance of the task.

Practical Ergonomic Tips

To optimize ergonomics while using a screen protector cutter, consider the following practical tips:

- Adjust Workstation Height: Ensure that the cutting surface is at a comfortable height to prevent strain on the back and arms. A workbench or table that allows the user to stand comfortably or sit with their feet flat on the ground is ideal.

- Use Ergonomic Accessories: Implement tools such as wrist rests or cushioned mats to reduce fatigue during extended use. This can help in maintaining proper posture and preventing discomfort.

- Frequent Breaks: Encourage users to take short, regular breaks to stretch and change positions. This practice can help alleviate tension and improve overall well-being during lengthy cutting sessions.

- Proper Tool Design: Utilize cutters that are specifically designed with ergonomic handles, which can help in reducing the strain on the hands and fingers during operation. By prioritizing these ergonomic practices, users can enjoy a more comfortable and efficient experience while working with screen protector cutters, ultimately leading to improved performance and reduced injury risk.

Comments

Comparing Flexible Hydrogel Films with Traditional Protective Films

The choice between flexible hydrogel films and traditional protective films hinges on your needs for flexibility, durability, and ease of application, with hydrogel films offering a versatile, modern solution and traditional films providing robust protection for flat screens.

How Much Does a Phone Repair Cost?

understanding phone repair costs and options is essential for making informed decisions about your device’s care.

How to Start Phone Accessories Business

Starting a phone accessories business involves a multifaceted approach that combines market research, business planning, legal compliance, product selection, sourcing, branding, and effective marketing strategies.

New 0.18mm Thickness Self-Repair EPU Hydrogel Film Protector

When choosing between PET film and the more cost-effective EPU kit, there are several important similarities and differences to consider.

Both PET and EPU films are designed to offer high transparency, ensuring that the screen’s clarity and vividness remain unaffected. They both maintain the phone’s original display quality, offering crystal-clear visuals whether you’re watching videos or browsing photos.

A key difference, however, lies in the durability and shock absorption of the materials. While PET provides a rigid, glass-like feel, it doesn’t offer the same level of impact protection as EPU films. EPU films are engineered with hydrogel technology, which not only makes them more flexible but also significantly better at absorbing shocks, protecting your phone from accidental drops and impacts. This makes EPU a better choice for users who want both protection and flexibility.

How to Put on an iPhone Screen Protector: A Step-by-Step Guide

Applying a screen protector to your iPhone is essential for maintaining its pristine condition and protecting it from scratches and cracks. This article will guide you through the process of installing a A sticky side of your tempered glass screen protector is crucial for proper installation. effectively, ensuring that you do it without damaging your phone screen. Whether you’re a first-time user or looking to improve your technique, this guide is worth reading for its practical tips and insights.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.