How a Screen Protector Machine Can Save You Money

Table of Contents

Summary

These machines offer substantial benefits, including reducing inventory costs, providing flexible production methods, and enhancing the quality and consistency of screen protectors. By investing in a screen protector machine, businesses can meet diverse consumer needs more efficiently and cost-effectively, ultimately boosting profitability and customer satisfaction.

Screen protector machines come in various types, each offering different levels of complexity and functionality. Basic models are user-friendly and can quickly produce protectors from materials like HD, matte, and anti-blue light films. Advanced machines offer greater versatility, handling more specialized materials such as self-healing and UV films, while hybrid machines combine multiple materials to create screen protectors with enhanced protective qualities. Custom machines are tailored to produce protectors that fit specific device models precisely, ensuring seamless fit and comprehensive protection. Multifunctional models, such as the MTB-CUT M288, offer capabilities ranging from cutting to installing and UV curing, making the production process more efficient and user-friendly.

The financial benefits of using a screen protector machine are notable. These ma- chines significantly reduce inventory costs by allowing businesses to produce screen protectors on-demand, thereby eliminating the need for large inventories. The versatility in material usage also means that businesses can cater to a broader market without maintaining separate inventories for each type of protector, further reducing storage and management costs. Additionally, the high quality and consistency of screen protectors produced by these machines minimize the likelihood of returns and enhance customer satisfaction, which can lead to increased sales and profitability. Despite the initial investment required for a screen protector machine, the long-term savings and potential revenue gains make it a financially prudent choice. With prices for these machines and the protective films they use varying based on quality and functionality, businesses can optimize their production to include both low-cost and premium options, maximizing profit margins. Furthermore, the reduced need for repairs or replacements of damaged screens underscores the cost-effectiveness of using custom cut screen protectors. Overall, the adoption of screen protector machines can lead to substantial economic advantages for businesses in the screen protector industry.

Types of Screen Protector Machines

Screen protector machines are becoming increasingly popular for creating on-demand screen protectors for various electronic devices such as smartphones, tablets, and smartwatches. These machines offer significant advantages, including reducing inventory costs and providing flexible production methods to meet diverse consumer needs.

Basic Screen Protector Machines

Basic screen protector machines are designed for simplicity and ease of use. They typically allow users to cut common materials like HD, Matte, and anti-blue light films. These machines can produce screen protectors quickly, which is critical for reducing inventory and increasing profitability.

Advanced Screen Protector Machines

Advanced screen protector machines incorporate additional features that make them more versatile and efficient. These machines can handle a wider range of materials, including self-healing and UV films with higher hardness or anti-explosion properties. They also offer various patterned back films, giving users more options to customize their screen protectors.

Hybrid Screen Protector Machines

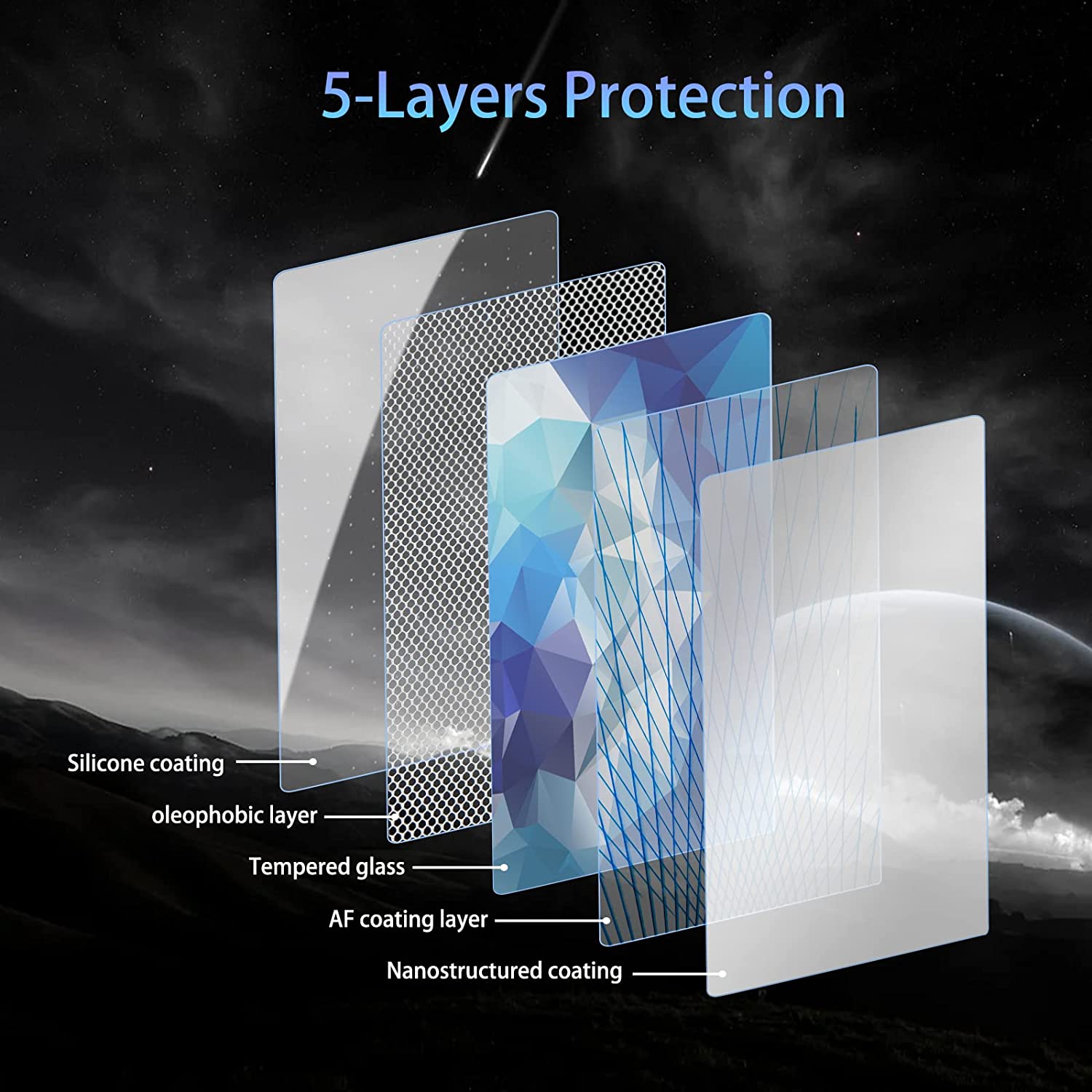

Some advanced machines are capable of producing hybrid screen protectors, which combine multiple materials to achieve a balance of properties. For instance, a hybrid screen protector may feature a tempered glass layer for enhanced hardness and scratch resistance, along with a TPU or PET layer for flexibility and impact absorption. This comprehensive protection solution leverages the best characteristics of each material.

Custom Screen Protector Machines

Custom screen protector machines are designed to create protectors that fit specific device models precisely. These machines ensure a seamless fit and complete coverage, protecting the device’s edges and corners from scratches, cracks, and other physical damage. The precision and durability offered by custom machines make them a practical and long-lasting solution for device protection.

Multifunctional Screen Protector Machines

Some screen protector machines, like the MTB-CUT M288, offer multifunctional capabilities. These machines can handle everything from cutting to installing and UV curing the screen protectors. They come equipped with various installation modes to accommodate different materials and often include additional tools like cutting blades, a non-slip mat, and a power adapter. These comprehensive kits make the process more efficient and user-friendly.

By understanding the different types of screen protector machines available, consumers and businesses can choose the one that best meets their needs, providing efficient and cost-effective solutions for device protection.

How Screen Protector Machines Work

Screen protector machines are designed to produce screen protectors on-demand for a variety of electronic devices, such as smartphones, tablets, and smartwatches. These machines offer significant benefits to the screen protector industry, making them increasingly popular.

Production Process

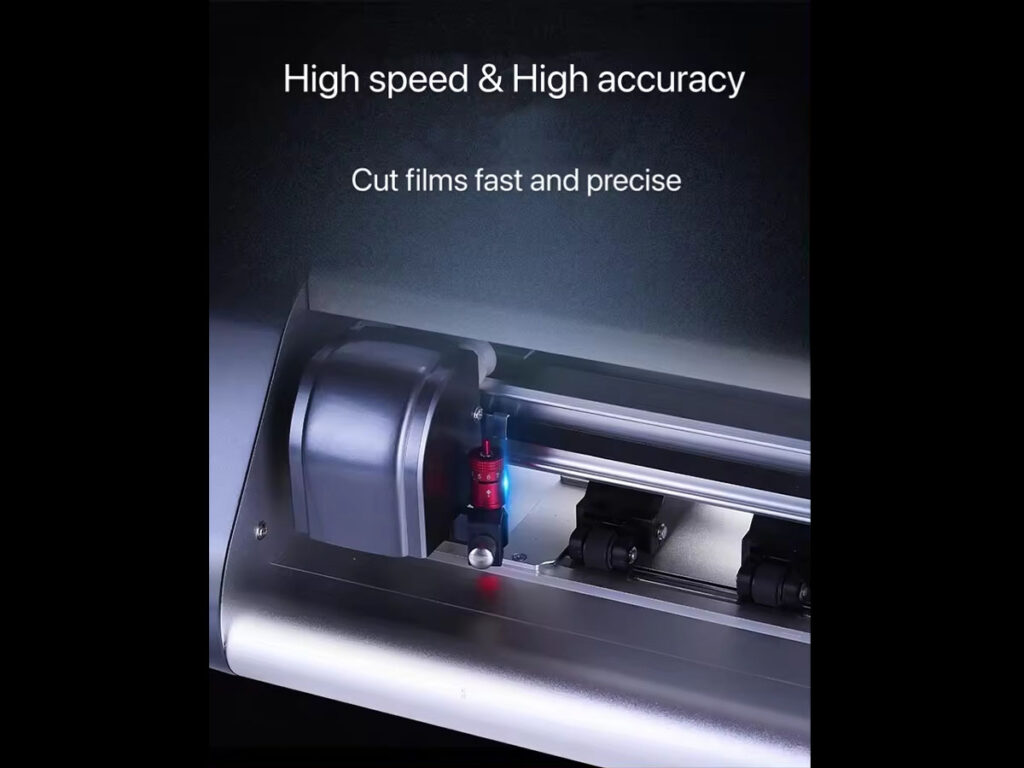

The production process of screen protector machines involves using common materials to cut out screen protectors quickly and efficiently. This process eliminates the need to maintain a large inventory of screen protectors for each mobile phone model, thereby reducing inventory costs and increasing profitability. Users can cut various types of screen protector materials with these machines, including HD, Matte, anti-blue light, self-healing, UV film with higher hardness, and anti-explosion screen protectors. Additionally, these machines can produce various patterned back films, offering a flexible production method to meet diverse consumer needs.

Functionality and Features

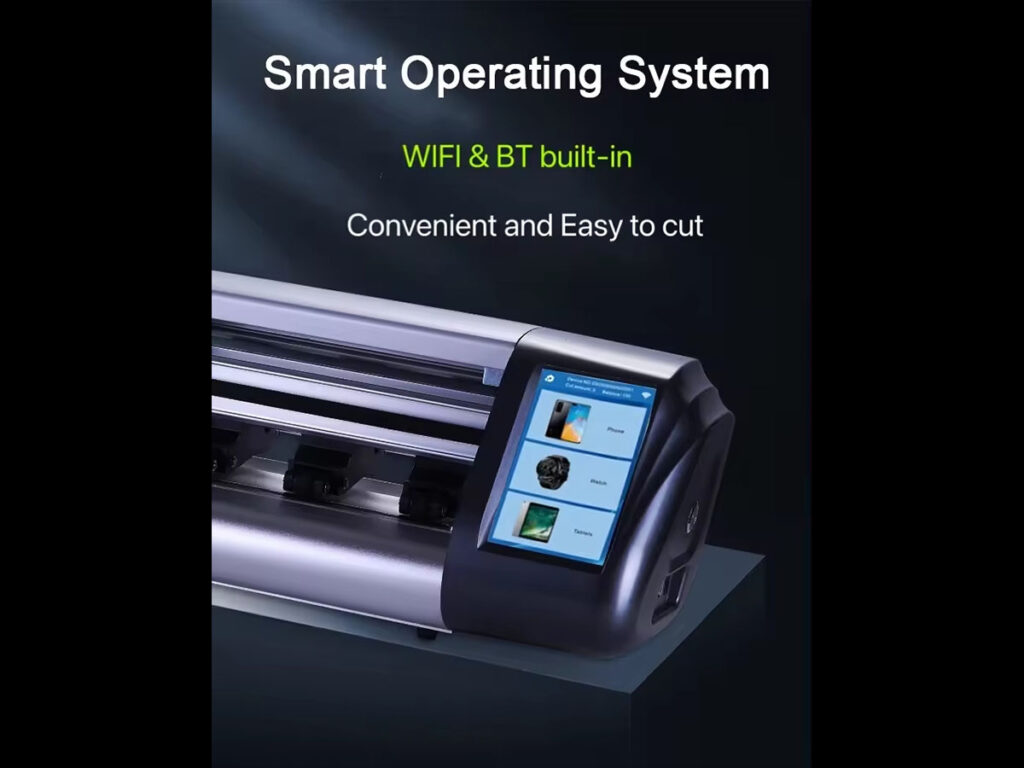

Screen protector machines come equipped with an intuitive operation screen inter- face. Key functions include quick search, product selection, consumable inventory management, and statistical data viewing. Users can connect the machine to WiFi, adjust settings, and check daily, weekly, and monthly cutting data.

Furthermore, some machines support additional features such as customer engagement through cutting times, ensuring dealers can stay connected with their clientele. Quality control and efficient production processes are maintained using digital work instructions, which help achieve high-quality outputs consistently.

Application and Removal

Modern screen protectors designed for use with these machines often come with easy-to-follow application instructions and tools, making the process foolproof. Some protectors use a wet application method that allows for easier positioning and adjustment before drying, while others feature alignment tabs or stickers for a perfect fit.

The removal process has also seen significant advancements. Older screen protectors often left residue or damaged the screen upon removal. In contrast, newer screen protectors use adhesive materials that ensure clean and easy removal without any residue or damage to the device.

Enhancing User Experience

Screen protectors produced by these machines are not just about protection; they can also enhance the user experience in several ways. Some screen protectors now come with privacy filters, glare reduction, antimicrobial coatings, and self-healing properties, making them more than just a protective layer but also a means to improve device usability and hygiene.

By investing in a screen protector machine, businesses can offer a comprehensive and customizable solution to protect and enhance electronic devices, ensuring customer satisfaction and loyalty.

Financial Benefits of Using a Screen Protector Machine

The use of a screen protector machine offers several financial benefits, especially for businesses in the screen protector industry. One of the primary advantages is the reduction in inventory costs. Traditional methods require businesses to stock a wide variety of screen protectors for different device models, leading to significant inventory expenses. However, a screen protector machine allows businesses to produce custom screen protectors on-demand, eliminating the need for large inventories and thereby reducing overhead costs.

Another financial benefit is the versatility in material usage. Screen protector ma- chines can cut various types of materials, including HD, matte, anti-blue light,self-healing, and UV film, among others[1]. This flexibility enables businesses to meet diverse consumer needs without having to maintain separate inventories for each type of material, further reducing storage and management costs.

Additionally, custom cut screen protectors are cost-effective solutions compared to the potential expenses associated with repairing or replacing damaged screens. By investing in a screen protector machine, businesses can offer tailored solutions to their customers, enhancing customer satisfaction and potentially increasing sales.

The cost of screen protectors varies significantly depending on the material. Plastic screen protectors typically cost less than $15, while glass screen protectors can range from $10 to $50. With a screen protector machine, businesses can optimize their production to include both low-cost and premium options, catering to a broader market and maximizing profit margins.

Quality and Consistency

In the realm of screen protector production, maintaining high quality and consistency is paramount to achieving customer satisfaction and reducing costs. Utilizing a screen protector machine can greatly enhance these aspects, resulting in significant benefits for manufacturers.

One of the major advantages of using screen protector machines is the ability to perform 100% quality tests before the goods are sent out. This thorough

inspection process ensures that every product meets the required standards, thereby minimizing the likelihood of returns and customer complaints. Factory outlets with professional technology and rigorous quality control teams contribute to maintaining consistent product quality. This structured approach allows manufacturers to detect and rectify any defects before the products reach the market, enhancing overall reliability.

Consistency in production is also achieved through the use of digital work instructions. Digital instructions can include built-in quality checks and seamless prompts to validate dimensions and confirm that the correct parts are assembled in the right order. This method has been proven to enhance the success rate of manufacturing processes, as demonstrated in an experiment where employees who followed digital instructions achieved a 100% OK rate compared to those who relied on printed instructions. Such practices ensure that the final products are consistently high in quality.

Additionally, applying a screen protector with the proper technique, such as using a plastic squeegee or a credit card to remove air bubbles, ensures that the screen protector adheres perfectly without compromising the screen’s integrity. This attention to detail during the application process guarantees a flawless finish, further contributing to the product’s quality and consistency.

Comparative Costs

When evaluating the economic benefits of a screen protector machine, it’s essential to consider both the upfront and ongoing expenses associated with its use.

A typical screen protector machine retails for around R11,000. In addition to the initial investment, there are costs associated with the protective films, which range from approximately R800 to R3,000 for a pack of 50 sheets, depending on the type and quality of the film[6]. For example, a pack of 50 clear screen protectors works out to R16.75 each.

In contrast, purchasing individual screen protectors can be significantly more ex- pensive. Plastic screen protectors typically cost less than $15, while glass screen protectors range between $10 and $50. This variation depends on factors such as material quality and protective capabilities. While the pricier options might justify their cost with features like lifetime guarantees, these often come with additional caveats like the need to pay return postage for replacements.

Furthermore, the cost-effectiveness of screen protectors extends beyond just their purchase price. Screen protectors are designed to absorb impact, thereby reducing the likelihood of damage to a phone’s expensive glass screen. Using a screen protector, which might cost around R50, can save the user thousands of dollars in potential screen replacement costs.

The economic advantages become even more pronounced when operating a business. The cost-effective cutting material offered by some screen protector machines is significantly cheaper than other screen plotters on the market. This allows businesses to offer a range of products, such as HD clear, matte, privacy, and anti-blue ray screen protectors, all at reduced purchase costs.

By comparing these costs, it’s clear that investing in a screen protector machine not only reduces per-unit costs but also enables business owners to maximize their profits by selling customized screen protectors at competitive prices.

Case Studies

We pride ourselves on delivering top-notch screen protective solutions tailored to meet the diverse needs of our business clients. Below is a small selection of businesses and organizations we’ve helped across various industries to enhance device longevity, improve employee productivity, and achieve cost savings. Explore these case studies to discover the real-world impact of ScreenShield’s commitment to quality and customer satisfaction.

Tasti Products

Tasti partnered with ScreenShield to produce custom-made screen protectors for their staff’s daily use. After finalizing the design and selecting optimal materials, the screen protectors entered production and were swiftly delivered to Tasti’s headquarters.

Pel-Air Aviation

Pel-Air Aviation’s collaboration with ScreenShield led to the development of premium clear film screen protectors, specifically designed for use on equipment within the Pel-Air fleet.

Coca-Cola Europacific Partners

Coca-Cola Europacific Partners benefited from ScreenShield’s expertise in providing tailored screen protective solutions, enhancing the durability and longevity of their devices used across various operational settings.

Environmental Impact

Implementing a screen protector machine in your manufacturing process can significantly reduce the environmental footprint of your operations. The ink removal and degreasing processes utilize non-volatile, biodegradable chemicals, which do not evaporate and thus do not require constant replenishment. This not only translates into substantial cost savings but also minimizes the environmental impact due to reduced chemical usage.

Moreover, the enclosed nature of the screen reclamation system helps in curbing water usage by recirculating both water and chemicals within the system. This approach is especially beneficial in regions where water is a scarce resource, thereby offering both environmental and financial benefits by lowering the overall consumption of water.

The automatic screen reclaim system also promotes a safer work environment. Traditional methods of screen cleaning expose workers to hazardous chemicals and vapors, whereas an enclosed system prevents such exposure, resulting in improved air quality and reduced health risks for employees. This safer work environment contributes to better productivity and lowers potential healthcare costs.

Adopting sustainable practices, such as recycling and using energy-efficient devices, further amplifies the positive environmental impact. These measures not only foster a greener manufacturing process but also lead to reduced operational costs, enhancing the overall financial health of the organization. Companies can thus achieve their sustainability goals while simultaneously improving their bottom line.

Buying Guide

When considering the purchase of a screen protector machine, several key factors should be taken into account to ensure you make the best decision for your needs.

Trade Shows and Networking

Attending trade shows can be highly beneficial for making connections with sales representatives, manufacturers, and other screen printing experts. These events often provide valuable tips and information, and the connections made can offer ongoing support and advice.

Ongoing Education

It’s crucial to engage in continuous learning to enhance your skills with automatic printing. For instance, Greg Kitson at Mind’s Eye Graphics in Decatur, IN, offers exceptional educational programs that can be highly beneficial. These programs provide hands-on experience and in-depth knowledge essential for operating and maintaining your screen protector machine.

New vs. Used Machines

One of the significant decisions you will need to make is whether to finance a new automatic press or purchase a used one. This choice depends on your ability to repair and maintain equipment, as well as the logistics of having a used press shipped to your location.

Budgeting and Cost Analysis

Creating a detailed budget is imperative for providing visibility into fiscal operations and enabling comprehensive tracking and control of expenditures. This budget should cover all aspects, from large-scale investments to daily expenses, allowing for an eagle’s view over finances and identifying potential areas for significant savings. Additionally, periodic reviews and adjustments are necessary to adapt to varying operational requirements or market conditions.

Evaluating Accessories and Additional Costs

While it may seem like there are many unnecessary accessories for your screen protector machine, some can be genuinely useful. Accessories like screen protectors can greatly improve your smartphone experience, though it’s important to weigh the protection level, ease of application, and any effects on the phone’s functionality. Additionally, understanding the production costs of components like core processors, display, memory, and camera modules can provide insight into overall expenses.

Employee Input and Optimization

Gathering employee input and ideas can uncover further cost-saving opportunities. Re-evaluating workplace benefits and ensuring they align with current employee preferences can also contribute to long-term cost-effectiveness.

By considering these factors, you can make a well-informed decision that balances cost, functionality, and ongoing maintenance needs, ultimately saving you money in the long run.

Comments

Phone Screen Protector Machine Pricing: What Small Businesses Need to Know

This surge in demand has led to a booming market for phone screen protectors, making it an attractive business opportunity for small enterprises.

Formula leopard 5 Navigation Tempered Glass

Protect your Formula Leopard 5’s navigation screen with our premium tempered glass protector.

UV Light Curing Machine for UV Sheet

The Universal UV Light Curing Machine for UV Sheet is crucial for businesses looking to deliver high-quality UV sheet applications, combining efficiency, durability, and user-friendly operation for outstanding results.

The Best Screen Protector for Your Phone of 2024

As we navigate an increasingly digital world, protecting our devices has never been more important.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.