How Smart Screen Protector Cutting Machines Revolutionize Mobile Accessory Production

Table of Contents

Extract

Summary

These advanced devices allow for on-demand cutting of screen protectors tailored to various mobile devices, significantly reducing the need for extensive inventories and enhancing operational efficiency.

The rise of smartphone usage has created a substantial demand for screen protectors, which, combined with the rapid evolution of device designs, necessitates flexible manufacturing solutions to meet consumer needs effectively. The technology behind smart screen protector cutting machines incorporates precision cutting, automated film feeding, and customization capabilities that streamline production processes and significantly reduce turnaround times. These machines can produce a screen protector in as little as 30 seconds, allowing businesses to adapt swiftly to new market trends and consumer preferences. As competition intensifies in the mobile accessory market, the efficiency and scalability offered by these machines have positioned many companies to achieve higher profit margins and faster market responses. While the advantages are considerable, the integration of smart cutting technology also poses challenges. Companies face initial investment costs, potential job displacement concerns due to automation, and the need for comprehensive employee training to ensure successful adoption. Moreover, operational disruptions during the transition to smart machines and dependence on external components can complicate production workflows, highlighting the importance of strategic planning in implementation. In summary, smart screen protector cutting machines not only enhance manufacturing capabilities but also reshape market strategies and consumer interactions within the mobile accessory sector. As technology continues to evolve, these machines are expected to drive innovations in production processes, sustainability, and employment dynamics, making them a notable focal point in the industry’s future.

History

The evolution of screen protector cutting machines is closely tied to advancements in technology and manufacturing processes. Initially, traditional screen protectors were pre-manufactured in standard sizes, leading to significant inventory pressures for retailers who struggled to stock a wide variety of models to accommodate the diverse range of mobile devices on the market

.

Technological Shift

In response to the limitations of traditional methods, the introduction of smart screen protector cutting machines marked a significant technological shift. These machines allowed retailers to cut screen protectors on demand, thus eliminating the need for extensive inventories of various sizes. This innovation not only reduced the capital occupation but also streamlined operations by enabling businesses to adapt quickly to new device models as they entered the market

.

Market Demand

The rise in smartphone usage in the early 21st century created an unprecedented demand for mobile accessories, particularly screen protectors

. However, this surge was coupled with challenges, such as the rapid evolution of device form factors, which necessitated a more flexible manufacturing solution. Screen protector cutting machines emerged as a viable answer, allowing manufacturers to produce customized protectors that fit perfectly on any device, including curved and foldable screens.

Emphasis on Efficiency

As competition intensified within the mobile accessory market, manufacturers sought ways to enhance operational efficiency. The advent of automatic film feeding technology in screen protector cutting machines further streamlined the production process, enabling operators to produce a protector in as little as 30 seconds

. This efficiency not only improved profit margins but also positioned companies to meet consumer demands swiftly, enhancing their market responsiveness.

Technology

Smart screen protector cutting machines represent a significant advancement in the mobile accessory production sector. These machines integrate a range of technologies that enhance their functionality and efficiency, transforming how screen protectors are produced and applied.

Features and Capabilities

Precision Cutting

The cutting machines utilize advanced technology to achieve extreme precision in cutting mobile phone screen protectors. With the ability to create smooth and flat cutting lines, these devices ensure that screen guards fit perfectly on the devices they are intended for, effectively covering the entire surface without any imperfections

.

On-Demand Customization

One of the standout features of these machines is their capacity for on-demand customization. They can cut flexible films into any desired size to match various digital devices, significantly reducing inventory pressure associated with traditional screen protector application methods

. This flexibility allows businesses to cater to a diverse range of models without the need for large stock inventories.

Time Efficiency

These machines are designed to optimize production time. For instance, they can complete the cutting process for a single film in just 30 seconds, which streamlines operations and conserves resources

. The automated film feeding system further enhances efficiency, allowing for a seamless cutting experience.

Advantages

Smart screen protector cutting machines offer numerous benefits that significantly enhance the efficiency and effectiveness of mobile accessory production.

Efficiency and Cost Reduction

One of the primary advantages of these machines is their ability to streamline operations. By homing in on value streams, manufacturers can cut out waste, allowing for the delivery of products at competitive prices while maintaining high quality.

This increased efficiency often translates to greater profitability and lower operational costs, as the machines automate processes that would otherwise require significant manual labor.

Employee Engagement

Moreover, smart cutting machines empower employees by allowing them to focus on problem-solving rather than routine tasks. This creates a strong organizational culture, fostering a workplace environment where team members feel valued and motivated to contribute new ideas. Such an environment is conducive to employee retention and satisfaction, which can lead to further innovations and cost savings for the company.

Scalability and Growth

The standardized processes provided by smart screen protector cutting machines facilitate easier scaling of operations to new locations or teams. Once optimized and codified, best practices can be easily transferred, which supports organizational growth and reduces the complexity of training new staff.

This scalability is essential in today’s rapidly evolving market where quick adaptation is vital for success.

Competitive Advantage

Implementing smart cutting technology also provides a significant competitive advantage. Research shows that companies with high operational efficiency have up to 25% higher growth and 75% higher productivity compared to their less efficient counterparts.

By ensuring that production aligns closely with customer demand, these machines help organizations remain agile in a dynamic marketplace.

Enhanced Quality Control

In addition to efficiency, smart cutting machines improve quality control throughout the production process. By minimizing variations and human errors, these machines contribute to consistently high-quality products. For example, enhanced pre-kitting of supplies and point-of-use tooling ensure that each stage of production is optimized for performance, leading to better overall outcomes for the end product.

Market Impact

Smart screen protector cutting machines have significantly transformed the mobile accessory production market, emphasizing operational excellence and technological integration. Companies leveraging these machines have reported enhanced efficiency and sustained impact over time by adopting end-to-end value-stream principles. For instance, some manufacturers utilize artificial intelligence to optimize their production processes, effectively linking production to market demands and customer feedback, thus streamlining the value stream from raw material to final product delivery

. Moreover, the deployment of these machines supports innovative practices within the supply chain. By connecting operators with sales representatives and customers, organizations have fostered a sense of purpose among workers, directly influencing productivity and quality control. This direct feedback loop has proven to be a powerful motivator, driving operational improvements that align with customer needs. In addition to operational efficiency, smart screen protector cutting machines play a crucial role in personalized marketing efforts. Advanced algorithms enable businesses to better understand consumer preferences and tailor their product offerings accordingly. Automated marketing techniques powered by AI, such as targeted advertisements and real-time analytics, have proven effective in increasing consumer engagement and driving sales. This blend of production efficiency and marketing innovation not only boosts profitability but also aligns with consumer expectations in an increasingly competitive landscape. Furthermore, the integration of these machines has broader implications for market dynamics. As production processes become more efficient, companies can respond rapidly to shifting market trends, thereby maintaining competitiveness. The use of such advanced technologies mitigates the risks associated with traditional manufacturing practices, such as overproduction and waste, ultimately contributing to a more sustainable production model. Thus, smart screen protector cutting machines are not just enhancing operational capabilities; they are also reshaping market strategies and consumer interactions in the mobile accessory sector.

Challenges

The integration of smart screen protector cutting machines into mobile accessory production has introduced several challenges that need to be addressed for optimal functionality and effectiveness.

Technical and Operational Risks

Integration Difficulties

Integrating new smart screen protector cutting machines into existing production workflows can lead to operational disruptions. These machines often require significant alterations to current processes, which can cause temporary inefficiencies during the transition phase

.

Dependence on External Components

The reliance on external components for these machines can introduce complications. Issues such as compatibility with existing equipment, supply chain disruptions for parts, and the need for specialized training for staff can all impact production timelines and costs

.

Maintenance and Support

The maintenance of smart screen protector cutting machines poses another challenge. Regular upkeep is essential to avoid operational failures, and ensuring that technical support is readily available can be problematic, especially in remote production locations. This challenge is exacerbated when project ownership changes or when key personnel become unavailable

.

Market and Economic Considerations

Cost Implications

The initial investment in smart cutting machines can be substantial. Companies must evaluate the long-term return on investment against these upfront costs, taking into consideration both potential operational efficiencies and market volatility

.

Job Displacement Concerns

As these machines automate certain tasks, there is a growing concern regarding job displacement within the workforce. While the machines can enhance efficiency, they may also lead to a reduction in the number of required skilled workers, creating socio-economic challenges in the industry

.

Uncertainty in Market Adaptation

The pace at which companies can adapt to the new technology varies significantly. While some organizations may quickly realize the benefits, others might struggle due to inadequate market information or internal resistance to change, leading to inconsistent service quality and increased operational risks

.

User Acceptance and Training

User Training Requirements

To maximize the benefits of smart screen protector cutting machines, employees must receive comprehensive training. The complexity of these machines means that without proper understanding and operation, there may be increased risks of errors and reduced productivity

.

User Acceptance

The acceptance of smart technology among workers can be a barrier. Resistance to change from traditional methods to automated systems can create friction within teams, requiring careful management and communication strategies to ensure successful implementation

.

Future Trends

As technology continues to evolve, the future of mobile accessory production, particularly in the realm of screen protector cutting machines, is poised for significant advancements. Experts anticipate a transformative decade leading up to 2030, characterized by a blend of human ingenuity and technological innovation. This co-evolution of human skills and advanced machinery is expected to enhance productivity while fostering new opportunities in various sectors, including mobile accessories

.

Technological Integration

Emerging technologies will likely integrate artificial intelligence (AI) and sophisticated networking systems, thereby streamlining operations in mobile accessory production. The automation of processes, such as automatic film feeding and precise cutting capabilities, promises to improve efficiency and reduce human error. For instance, machines capable of cutting screen protectors in under 30 seconds represent a paradigm shift that not only saves time but also minimizes inventory concerns for retailers

.

Market Dynamics

The introduction of smart screen protector cutting machines is anticipated to meet growing consumer demands for customization and rapid production. By utilizing advanced technologies, such as the hydrogel film cutting machine, manufacturers can cater to a broader range of devices—extending beyond smartphones to tablets and smartwatches. This versatility, combined with a database of over 26,000 models, positions these machines to adapt quickly to market changes and consumer preferences

.

Impact on Employment

Contrary to fears that automation will displace human workers, the historical trend suggests that technology often creates more jobs than it eliminates. Industry experts express optimism that the expansion of AI will augment human capabilities, leading to the creation of new roles within mobile accessory production and beyond. As companies increasingly rely on these smart machines, the need for skilled operators and technicians will likely rise, ensuring a balance between human and machine contributions

.

Sustainability and Innovation

Future trends also indicate a heightened focus on sustainability in production processes. Innovations in materials, such as eco-friendly screen protectors, and energy-efficient cutting technologies are expected to gain traction. This shift will not only improve the environmental footprint of mobile accessory production but also resonate with consumer preferences for sustainable products

.

Comments

How to Take Air Bubbles Out of Screen Protector?

By following these tips, you’ll not only remove air bubbles but also become a pro at applying screen protectors without frustration. A little patience and the right techniques go a long way toward achieving a flawless, bubble-free screen!

When to Replace Phone Screen Protector

By keeping these points in mind, you can ensure that your smartphone remains protected and in excellent condition.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

The impact of technological progress on the price of mobile phone screen protectors

The impact of technological progress on the price of mobile phone screen protectors is a multifaceted topic that explores how advancements in materials and manufacturing techniques have transformed this market.

Mastering Screen Protector Cutters: Best Practices for a Snug Fit

Mastering screen protector cutters involves understanding the evolution, types, materials, and best practices essential for achieving a snug fit and optimal device protection.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

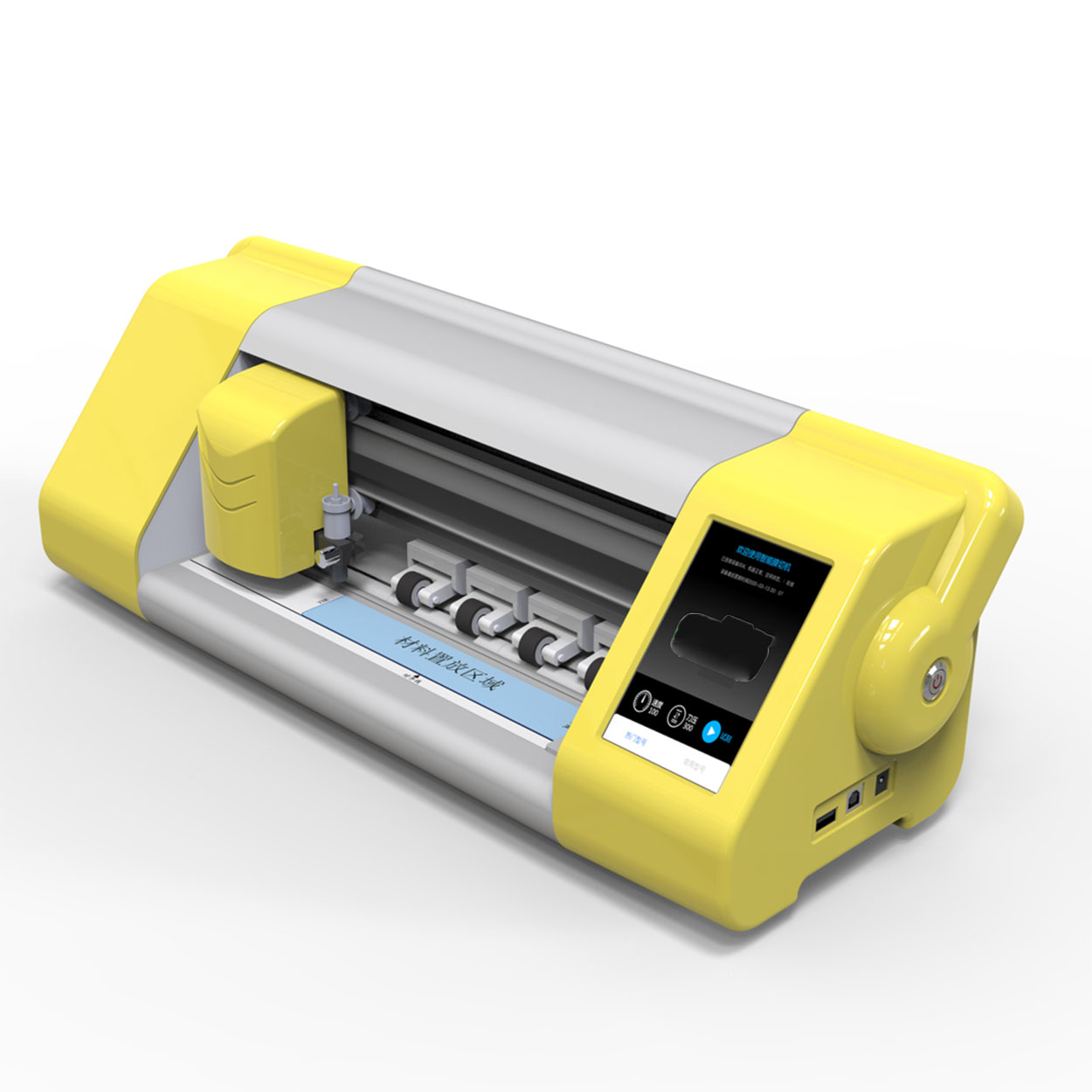

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

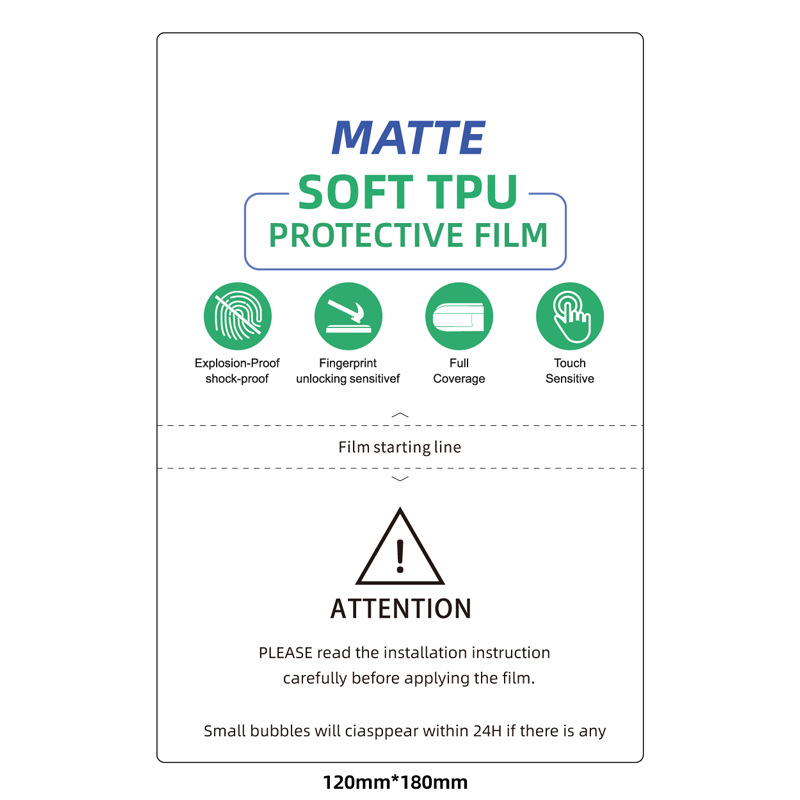

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.