How to choose the best screen protector factory for your business

Table of Contents

Extract

Summary

Choosing the right screen protector factory for your business is a crucial decision that can significantly impact your product quality, customer satisfaction, and overall profitability. With the growing demand for screen protectors for smartphones, tablets, laptops, and other devices, finding a reliable manufacturer is more important than ever. This comprehensive guide will walk you through the key factors to consider when selecting the best screen protector factory for your business, ensuring that you make an informed decision that aligns with your business goals.

Understanding Your Business Needs

Before diving into the selection process, it’s essential to have a clear understanding of your business needs. This involves assessing the type of screen protectors you want to offer, the volume of production, and your target market. Are you catering to high-end smartphones, budget devices, or specialized gadgets? Do you need screen protectors for a wide range of devices, or are you focusing on specific models?

Understanding these aspects will help you identify factories that specialize in the type of screen protectors you need. For instance, if your business focuses on premium screen protectors with advanced features like anti-glare or privacy filters, you’ll want to find a factory with expertise in these areas. Conversely, if you’re targeting budget-conscious consumers, a factory that offers cost-effective solutions may be more suitable.

Evaluating Production Capabilities

One of the most critical factors to consider when choosing a screen protector factory is its production capabilities. This includes the factory’s capacity to produce large quantities of screen protectors within your required timeframe, as well as its ability to handle custom orders or special requirements.

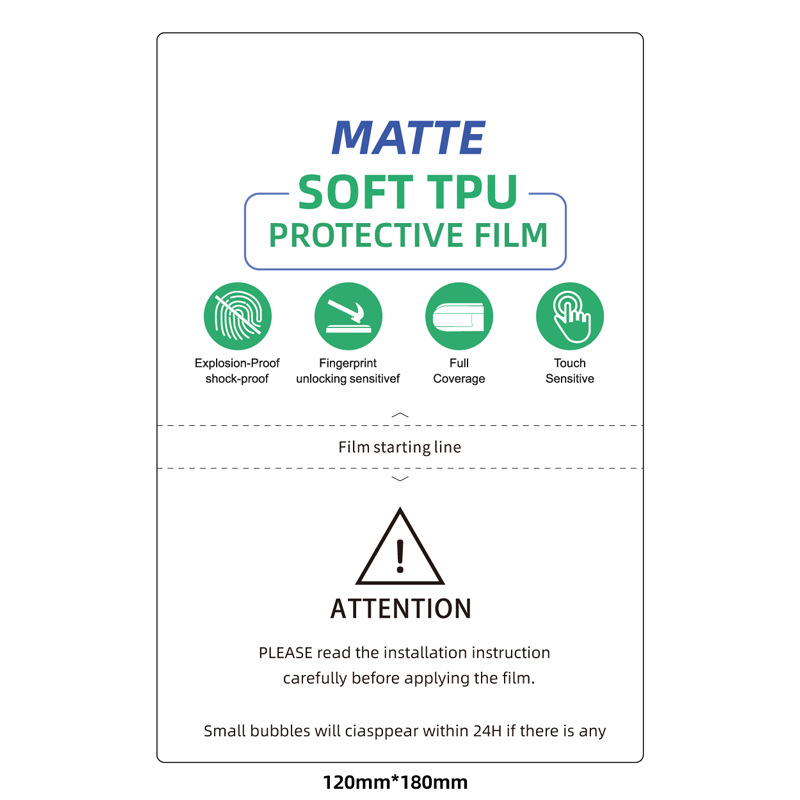

Start by asking the factory about its production volume, lead times, and flexibility in scaling production up or down based on demand. It’s also essential to inquire about the types of materials the factory uses, as different materials can affect the durability, clarity, and feel of the screen protectors. For example, some factories may specialize in tempered glass protectors, while others may focus on PET film or TPU protectors.

Additionally, consider the factory’s technological capabilities. Factories with modern, automated equipment are more likely to produce consistent, high-quality products. Advanced machinery can also reduce production times and minimize defects, leading to better overall product quality.

Quality Control and Assurance

Quality control is another vital aspect to consider when selecting a screen protector factory. The quality of the screen protectors you offer directly impacts customer satisfaction and your brand’s reputation, so it’s essential to partner with a factory that prioritizes quality at every stage of production.

When evaluating a factory’s quality control processes, ask about the specific measures they take to ensure product consistency and reliability. This may include inspections of raw materials, in-process quality checks, and final product testing. Some factories may also offer additional quality assurance services, such as third-party testing or certifications.

It’s also worth asking about the factory’s defect rate and how they handle defective products. A low defect rate indicates a well-managed production process, while a clear and efficient process for addressing defects shows that the factory is committed to maintaining high standards.

Customization and Flexibility

In today’s competitive market, offering customized products can set your business apart from the competition. Whether it’s custom packaging, branding, or specific features like privacy filters or anti-glare coatings, the ability to offer tailored products can be a significant advantage.

When choosing a screen protector factory, consider its ability to accommodate custom orders. This includes the factory’s willingness to work with you on design modifications, branding elements, and any unique features you want to incorporate into your screen protectors.

It’s also essential to assess the factory’s flexibility in terms of order sizes. Some factories may have minimum order quantities that are too high for small or medium-sized businesses, while others may be more accommodating. Finding a factory that can meet your specific needs, whether you’re placing small test orders or large bulk orders, is crucial for maintaining a smooth and efficient supply chain.

Pricing and Cost Management

Pricing is always a critical factor in any business decision, and choosing a screen protector factory is no exception. However, it’s important to strike a balance between cost and quality. While it’s tempting to choose the cheapest option, lower prices can sometimes mean lower quality, which can harm your brand’s reputation and lead to higher long-term costs due to returns, replacements, and lost customers.

When evaluating a factory’s pricing, consider all the factors that contribute to the final cost, including materials, production processes, labor, and shipping. It’s also essential to inquire about any additional fees, such as setup costs, custom order fees, or penalties for small orders.

In addition to the base price, consider the factory’s payment terms. Some factories may require full payment upfront, while others may offer more flexible payment options, such as partial payments or net terms. Choosing a factory with payment terms that align with your cash flow needs can help you manage costs more effectively.

Communication and Customer Service

Effective communication is crucial for a successful partnership with your screen protector factory. From the initial inquiry to ongoing production, clear and consistent communication ensures that your expectations are met and any issues are promptly addressed.

When evaluating a factory’s communication practices, consider factors such as response times, language proficiency, and the willingness of the factory’s representatives to answer your questions and provide detailed information. A factory that values communication will be more likely to work with you collaboratively and proactively address any challenges that arise.

Customer service is also an important consideration. A factory that offers strong customer support can help you navigate any issues that arise during production, from design modifications to shipping delays. Look for a factory that provides dedicated account managers or customer support representatives who can assist you throughout the production process.

Location and Shipping

The factory’s location is another critical factor to consider, as it can impact shipping costs, lead times, and your ability to visit the factory for inspections or audits. While many screen protector factories are located in Asia, particularly in China, it’s essential to weigh the pros and cons of different locations.

Factories in close proximity to your target market can reduce shipping costs and lead times, making it easier to meet customer demands. However, factories in countries with lower labor costs may offer more competitive pricing, even when factoring in higher shipping expenses.

When evaluating a factory’s location, also consider the logistics of shipping, including the availability of reliable shipping carriers, customs regulations, and potential delays. Some factories may offer shipping services or partnerships with logistics providers, which can simplify the process and reduce costs.

Reputation and Experience

The reputation and experience of a screen protector factory are strong indicators of its reliability and the quality of its products. A factory with a long history in the industry is more likely to have established quality control processes, experienced staff, and a track record of satisfied customers.

When researching potential factories, look for customer reviews, testimonials, and case studies that highlight the factory’s strengths and any potential weaknesses. You can also ask for references from the factory’s previous clients to gain insights into their experiences.

In addition to reputation, consider the factory’s experience in producing the specific type of screen protectors you need. A factory with experience in producing high-end tempered glass protectors, for example, may be better equipped to meet your quality standards than one that primarily produces lower-cost film protectors.

Compliance and Certifications

Compliance with industry standards and certifications is another important factor to consider when choosing a screen protector factory. Certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and RoHS compliance for hazardous substances demonstrate a factory’s commitment to meeting industry standards and regulations.

In addition to industry-specific certifications, consider any country-specific regulations that apply to your products, such as the CE marking in Europe or FCC compliance in the United States. Partnering with a factory that is familiar with and compliant with these regulations can help you avoid costly delays or issues when bringing your products to market.

Long-Term Partnership Potential

Finally, consider the long-term potential of your partnership with the screen protector factory. Building a strong, long-term relationship with your manufacturer can lead to better pricing, improved product quality, and more efficient communication over time.

When evaluating a factory’s long-term partnership potential, consider factors such as its financial stability, capacity for growth, and willingness to invest in new technologies or processes. A factory that is financially stable and forward-thinking is more likely to be a reliable partner for your business in the years to come.

It’s also important to assess the factory’s commitment to continuous improvement. Factories that regularly invest in new equipment, training for their staff, and process improvements are more likely to keep up with industry trends and deliver high-quality products that meet your evolving needs.

Conclusion

Choosing the best screen protector factory for your business is a complex decision that requires careful consideration of multiple factors. By thoroughly evaluating your business needs, the factory’s production capabilities, quality control processes, pricing, communication practices, and long-term partnership potential, you can make an informed decision that sets your business up for success.

A strong partnership with the right screen protector factory can lead to high-quality products, satisfied customers, and a competitive edge in the market. Take the time to research and vet potential factories, and don’t hesitate to ask detailed questions to ensure that the factory you choose aligns with your business goals and expectations.

Comments

The Benefits of Flexible Hydrogel Films for Wearable Devices

Flexible hydrogel films have emerged as a groundbreaking material for wearable devices, offering a unique blend of biocompatibility, mechanical flexibility, and responsiveness to environmental stimuli.

Laptop Screen Protector Hydrogel Film Cutting Machine

Home Email What’sApp Product Parameters CONTROL:APP control / Bluetooth LCD TOUCH SCREEN : 5.5″ HD with system CONNECTION : WIFI

How to Vet a Screen Protector Factory Before Partnering

When establishing a screen protector manufacturer partnership, it is critical to fully review the factory’s quality, risk, compliance, and communication strategies to ensure product quality and successful collaboration.

Smart Privacy Screen Cutting Machine: The Ultimate Guide for Businesses

Smart Privacy Screen Cutting Machines are advanced devices integrating smart technology to efficiently produce customized privacy screens, catering to growing digital privacy concerns across various industries.

Wholesale Best Self Healing Cell Phone Screen Protector

Provide your customers with the ultimate in screen protection. Our Wholesale Self Healing Screen Protectors offer unmatched durability and clarity.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.