What is a Intelligent Film Cutting Machine and How Does it Work?

A intelligent film cutting machine is a specialized device designed to cut protective films for various electronics, such as smartphones, tablets, and laptops. These machines use advanced technology—lasers, blades, or AI systems—to produce precisely shaped films that fit specific device models perfectly. Here’s an overview of the cutting process:

Loading the film: Insert a piece of TPU hydrogel into the machine.

Input device specifications: The desired device model is selected from a pre-loaded template.

Cutting: Using precision blades, the machine cuts the film according to the specified dimensions.

Application-ready film: The cut screen protector is ready for use.

This process is a game-changer in the screen protector industry by enhancing production speed and reducing waste, ensuring that every screen protector is tailored to fit its corresponding device model.

Why Are Film Cutting Machines Essential for Screen Protector Production?

Intelligent film cutting machine have become indispensable for companies and individuals involved in screen protector production due to the following reasons:

Precision: These machines cut films with unmatched accuracy, ensuring a perfect fit for all device models.

Efficiency: Capable of high-speed production, they drastically improve workflow and output.

Versatility: Many machines can handle different materials like TPU, hydrogel,UV, and EPU.

Cost-effectiveness: By minimizing waste and labor costs, they deliver a high return on investment (ROI).

For businesses in the screen protection industry, investing in a film cutting machine can provide competitive advantages, enabling the rapid and cost-efficient production of screen protectors to meet growing demand.

Types of Intelligent Film Cutting Machine Available

Film cutting machines come in various sizes and functionalities to suit different production needs and budgets. The main types include:

MINI TPU Film Cutting Machines (180mm) : Small, compact machines perfect for low-volume production or personal use,meet the daily needs of mobile phone stores.

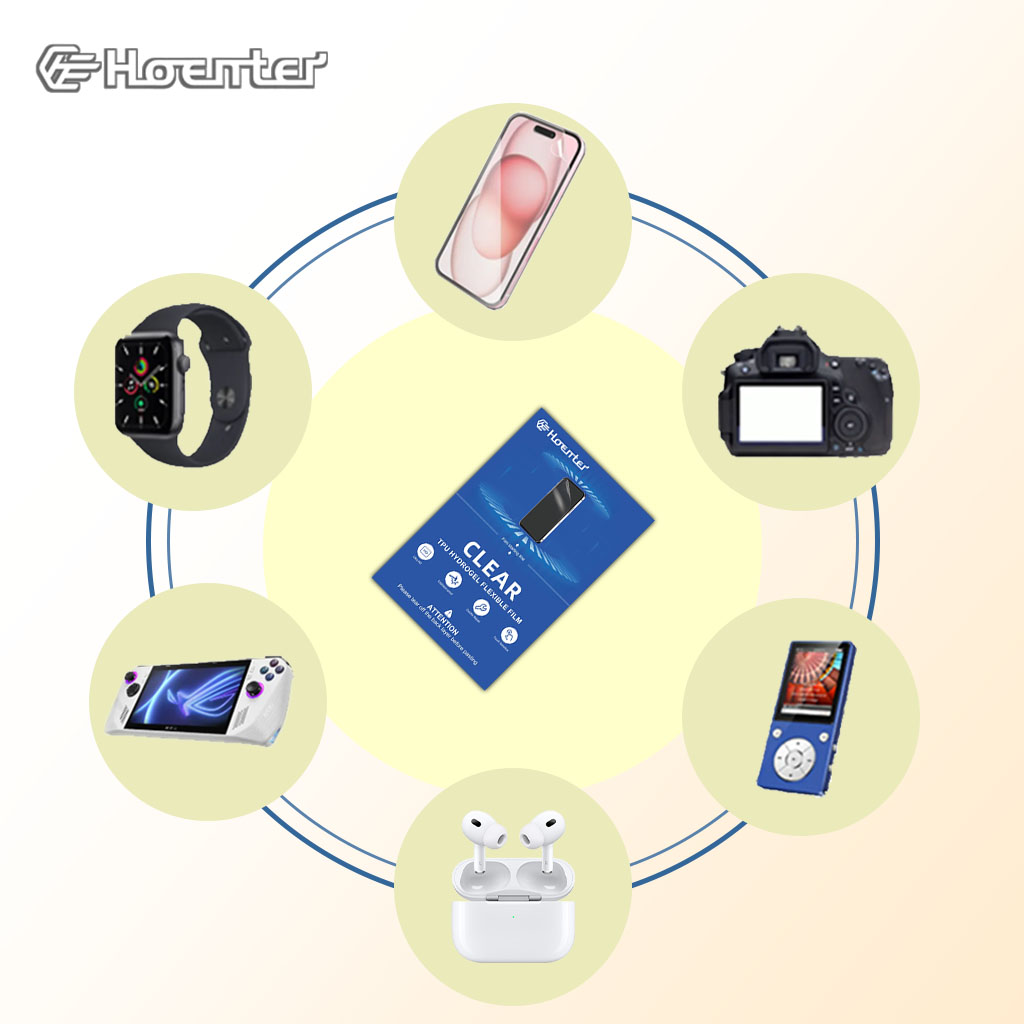

Table Intelligent Film Cutting Machines(230mm): Used to cut protective films for daily consumer electronic products such as mobile phones, tablets, watches, headphones, game consoles, etc., to expand the market

Laptop Hydrogel Film Cutting Machines(290mm): In addition to cutting protective films for daily consumer electronic digital products, it can also cut large-sized protective films for notebooks, car displays, etc.

Benefits of Using a Hydrogel Film Cutting Machine

Hydrogel screen protectors are gaining traction due to their unique self-healing properties, and machines designed to cut hydrogel films come with distinct advantages:

- Self-healing Properties: Hydrogel films repair minor scratches over time, providing long-lasting protection.

- Flexibility: Ideal for curved or irregular device screens.

- Precision: Specialized hydrogel cutters ensure clean, accurate cuts without damaging the film.

- Efficiency: These machines maintain speed without compromising on quality, ensuring fast production.

Hydrogel cutting machines, such as the our hydrogel film cutting machine, are well-suited for businesses focused on high-quality, flexible protection solutions.

How Intelligent Film Cutting Technology Improves Production

The rise of intelligent film cutting technology has revolutionized the screen protector production process. These machines utilize AI and cloud-based tools to optimize efficiency:

- AI-Assisted Cutting: AI optimizes cutting patterns to reduce material waste.

- Cloud Integration: Remote access to a database of device templates ensures compatibility with the latest models.

- Remote Monitoring: Allows operators to track and adjust production in real-time.

- Data Analytics: Provides insights into production trends, allowing for efficiency improvements.

With these features, intelligent cutting technology not only increases output quality but also streamlines operations, making them more cost-effective and scalable.

TPU in Screen Protector Production

TPU (Thermoplastic Polyurethane) is a popular material for screen protectors due to its combination of durability and flexibility. Film cutting machines are crucial in ensuring TPU films are cut to perfection:

- Flexibility: TPU’s elasticity requires precise handling during the cutting process.

- Precision: Machines ensure clean, accurate cuts, which are essential for TPU’s edge-to-edge coverage.

- Efficiency: High-speed cutting meets the rising demand for TPU-based protection.

- Customization: The ability to cut TPU films to different thicknesses and specifications is a key feature of these machines.

The demand for TPU-based screen protectors continues to grow, making film cutting machines that handle this material highly valuable.

Ensuring Perfect Fits for Different Devices

Achieving the perfect fit for a screen protector is essential for its effectiveness. Film cutting machines achieve this in several ways:

- Template Libraries: Machines come with comprehensive databases of device templates, ensuring compatibility.

- Customization: Operators can tweak dimensions for specific device models.

- Edge Detection: Sensors detect device edges to enhance accuracy.

- Multi-layer Cutting: Machines can cut complex shapes, such as notches or curved screens.

This ensures that each protector fits its intended device perfectly, improving customer satisfaction.

Maintenance for Film Cutting Machines

Proper maintenance is key to ensuring the longevity and performance of a film cutting machine. Common maintenance tasks include:

- Cleaning: Regular cleaning of cutting surfaces and internal components.

- Blade or Laser Replacement: Keeping cutting tools sharp or replacing worn lasers.

- Software Updates: Ensure that the machine stays compatible with the latest device templates.

- Calibration: Regular recalibration to maintain cutting accuracy.

- Lubrication: Lubricate moving parts to prevent wear and tear.

By maintaining the machine properly, businesses can ensure consistent, high-quality production.

Maximizing ROI with Film Cutting Machines

To maximize the return on investment (ROI) with film cutting machines, businesses should consider:

- Diversification: Expand into different device markets with customized screen protectors.

- Quality Improvement: Precision cutting leads to better customer satisfaction and reduced returns.

- Waste Reduction: Minimize material waste with optimized cutting patterns.

- Labor Efficiency: Automate the cutting process to save on labor costs.

- Customization: Offer niche products, such as custom-designed protectors for specialty devices.

By leveraging these advantages, businesses can position themselves to meet increasing demand and outshine competitors.