Phone Screen Protector Machine Pricing: What Small Businesses Need to Know

Table of Contents

Extract

Summary

As the demand for mobile devices continues to grow, so does the need for screen protection. This surge in demand has led to a booming market for phone screen protectors, making it an attractive business opportunity for small enterprises. However, before venturing into this market, it is essential to understand the factors that influence the pricing of phone screen protector machines. For small businesses, making an informed decision about which machine to invest in can mean the difference between profitability and overspending. This article will explore the critical elements that affect the pricing of these machines, helping small business owners navigate their options.

Understanding Machine Types and Their Impact on Pricing

One of the first considerations when evaluating the cost of a phone screen protector machine is the type of machine that best suits your business needs. The market offers a range of machines, each with different levels of automation and functionality, which directly influence their pricing.

- Manual Machines: These are the most basic and cost-effective options available. Manual machines require significant human intervention for operation, which may slow down production. However, they are ideal for small businesses with limited budgets or lower production demands. The lower initial investment makes manual machines an attractive option for startups or businesses testing the waters in the phone screen protector market.

- Semi-Automatic Machines: These machines offer a middle ground, providing a blend of manual operation and automation. While they are more expensive than manual machines, semi-automatic machines can increase production efficiency and consistency without the high cost of fully automated systems. For small businesses looking to scale up production gradually, semi-automatic machines can be a prudent investment.

- Fully Automatic Machines: These machines represent the top tier in terms of technology and automation, with minimal human intervention required. Fully automatic machines are capable of high-speed production, making them suitable for businesses with high output demands. However, the advanced technology and production capabilities come with a significant price tag, often making them less feasible for small businesses with limited capital.

The type of machine you choose should align with your business’s current and projected production needs. While fully automatic machines offer impressive efficiency, their high cost may not be justifiable for small businesses focused on steady, moderate growth.

Production Capacity and Its Influence on Cost

Production capacity is a crucial factor in determining the price of a phone screen protector machine. Machines with higher production capacities generally come at a higher price, but they also enable businesses to meet higher demand more efficiently.

- Low-Capacity Machines: These machines are designed for small-scale production, making them more affordable. They are well-suited for businesses that are just starting out or those that intend to maintain a niche market. However, low-capacity machines may limit growth opportunities if demand increases unexpectedly.

- Medium-Capacity Machines: These machines offer a balance between cost and production volume, providing a feasible option for small businesses looking to expand. They allow for moderate growth without the significant investment required for high-capacity machines.

- High-Capacity Machines: While these machines are the most expensive, they are essential for businesses aiming for large-scale production. High-capacity machines can produce thousands of screen protectors per day, but the substantial investment required can be a barrier for small businesses.

Small businesses need to assess their target market and production goals carefully. Overinvesting in a machine with more capacity than necessary can lead to unnecessary costs, while underinvesting may restrict your ability to meet growing demand. It’s essential to strike the right balance between capacity and cost to ensure sustainable growth.

Precision and Technology Features

The precision of the cutting and application processes is another key factor influencing the price of a phone screen protector machine. Machines equipped with advanced technology for higher precision generally come at a premium, but the investment can be worthwhile depending on your target market.

- Basic Precision Machines: These machines offer standard precision suitable for most common devices. They are usually less expensive and sufficient for businesses that produce screen protectors for standard smartphones without complex screen designs.

- High-Precision Machines: For businesses targeting high-end devices or those with curved screens and intricate designs, machines with advanced cutting technologies, such as laser cutters, are essential. These machines ensure a perfect fit and smooth edges, but they also come with a higher price tag.

Small businesses must consider the types of devices they plan to produce screen protectors for. If your business caters to a premium market with high expectations for precision, investing in a high-precision machine is crucial. However, if your target market consists of standard smartphone users, a basic precision machine may suffice and help you save on costs.

Material Compatibility and Versatility

The ability of a machine to work with different materials can significantly affect its price. Some machines are designed to handle a single type of material, while others can accommodate multiple materials such as tempered glass, hydrogel film, and PET film.

- Single-Material Machines: These machines are typically less expensive because they are designed for a specific type of material. They are a good choice for businesses that specialize in one type of screen protector, such as tempered glass.

- Multi-Material Machines: Machines that can handle various materials are more versatile but also more expensive. This versatility allows businesses to offer a wider range of products, catering to different customer needs and preferences.

For small businesses, the decision between a single-material and a multi-material machine should be based on the diversity of products they wish to offer. If your business plans to specialize in a particular type of screen protector, a single-material machine can reduce initial costs. However, if you aim to serve a broader market with multiple product offerings, the added investment in a multi-material machine may be justified.

Brand Reputation and Reliability

The reputation of the manufacturer and the perceived reliability of the machine are significant factors in pricing. Well-established brands with a history of producing high-quality, durable machines typically charge more for their products.

- Premium Brands: Machines from reputable brands are often more expensive due to their proven track record, superior build quality, and reliable customer support. These machines often come with longer warranties and better after-sales service, which can be important for small businesses looking for long-term reliability.

- Lesser-Known Brands: Machines from newer or lesser-known brands might be more affordable, but they could carry risks regarding quality and after-sales support. While these machines may seem like a cost-effective choice initially, they could result in higher long-term costs due to potential maintenance issues.

For small businesses, the choice between a premium brand and a lesser-known brand depends on their risk tolerance and the importance of long-term reliability. Investing in a machine from a reputable brand may reduce the likelihood of costly repairs and downtime, ultimately providing better value despite the higher upfront cost.

Customization Capabilities

Customization features can also influence the price of a phone screen protector machine. Some machines offer advanced customization options, allowing businesses to produce screen protectors tailored to specific customer needs or device specifications.

- Standard Machines: These machines come with predefined settings and templates, making them more affordable but less flexible. They are suitable for businesses focused on mass production of standard screen protectors.

- Customizable Machines: Machines with customization capabilities allow for adjustments in design, size, and material type. These machines are more expensive but enable businesses to cater to niche markets or offer personalized products.

For small businesses looking to differentiate themselves from competitors, investing in a customizable machine can be a strategic decision. The ability to offer unique, tailor-made products can attract a dedicated customer base and justify the higher machine cost.

Software Integration and Automation Levels

The extent of software integration and automation in a machine significantly affects its price. Machines with advanced software that automates various aspects of the production process are typically more expensive but offer substantial efficiency gains.

- Basic Machines: These machines require more manual intervention and have limited software integration. They are less expensive but may be more labor-intensive to operate.

- Advanced Machines: Machines with integrated software that automates design, cutting, and quality control processes are more costly. However, they can significantly reduce labor costs and production time, making them a valuable investment for businesses aiming to increase efficiency.

Small businesses should consider their workforce and production goals when choosing between basic and advanced machines. While advanced machines can increase productivity, the higher cost may not be necessary for businesses with lower production volumes or those that prefer a hands-on approach.

Geographic Location and Import Considerations

The geographic location of the manufacturer and related import costs can also influence machine pricing. Machines produced in different regions may have varying costs due to differences in labor, materials, and shipping.

- Domestic Machines: Machines manufactured locally may be more affordable due to lower shipping costs and import duties. Additionally, local machines may offer quicker access to support and replacement parts.

- Imported Machines: Machines from international manufacturers might be more expensive due to additional shipping costs, tariffs, and longer delivery times. However, they may offer advanced features or better technology that justifies the higher price.

Small businesses should weigh the benefits of domestic versus imported machines, considering factors such as cost, support, and technology. In some cases, the advanced features of an imported machine may outweigh the higher cost, especially if it provides a competitive edge.

Support, Warranty, and Maintenance Costs

The level of support, warranty, and maintenance services provided by the manufacturer can significantly affect the overall cost of a phone screen protector machine. Machines with comprehensive support and extended warranties are often priced higher but can offer better long-term value.

- Basic Support: Machines with limited warranties and minimal support services are generally less expensive. However, they may result in higher maintenance costs if issues arise, leading to potential downtime.

- Comprehensive Support: Machines with extended warranties, on-site support, and readily available spare parts are more expensive but reduce the risk of unexpected costs and production delays.

For small businesses, investing in a machine with robust support and warranty options can mitigate the risks associated with equipment failure, ensuring smoother operations and reducing the likelihood of costly disruptions.

Comments

How to Repair a Cracked Phone Screen

By equipping yourself with these tips and tricks, you can manage cracked screens efficiently and avoid unnecessary expenses.

Achieving Precision: Best Practices for a Snug Fit with Screen Protector Cutters

Achieving precision in cutting screen protectors is crucial for ensuring optimal device protection and user satisfaction.

The Impact of Smart Privacy Screen Cutting Machines on Data Security

Smart privacy screen cutouts play a vital role in enhancing data security, especially in preventing increasingly prevalent threats such as data breaches and visual theft.

Why Every Mobile Repair Shop Needs a Intelligent film cutting machine

The use of Intelligent Film Cutting Machines has become increasingly pivotal in modern mobile repair shops, significantly enhancing operational efficiency, precision, and customer satisfaction.

How to Put on a Screen Protector Perfectly: A Comprehensive Guide

Are you tired of botched screen protector applications that leave your phone looking worse than before? Applying a screen protector can be a daunting task, but with the right techniques, you can achieve a flawless finish that enhances your device’s appearance and protection. This guide will walk you through the process of putting on a screen protector perfectly, whether it’s a basic film or a premium tempered glass option. We’ll cover everything from preparation to troubleshooting, ensuring you have all the knowledge needed for a bubble-free, precisely aligned screen protector application.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

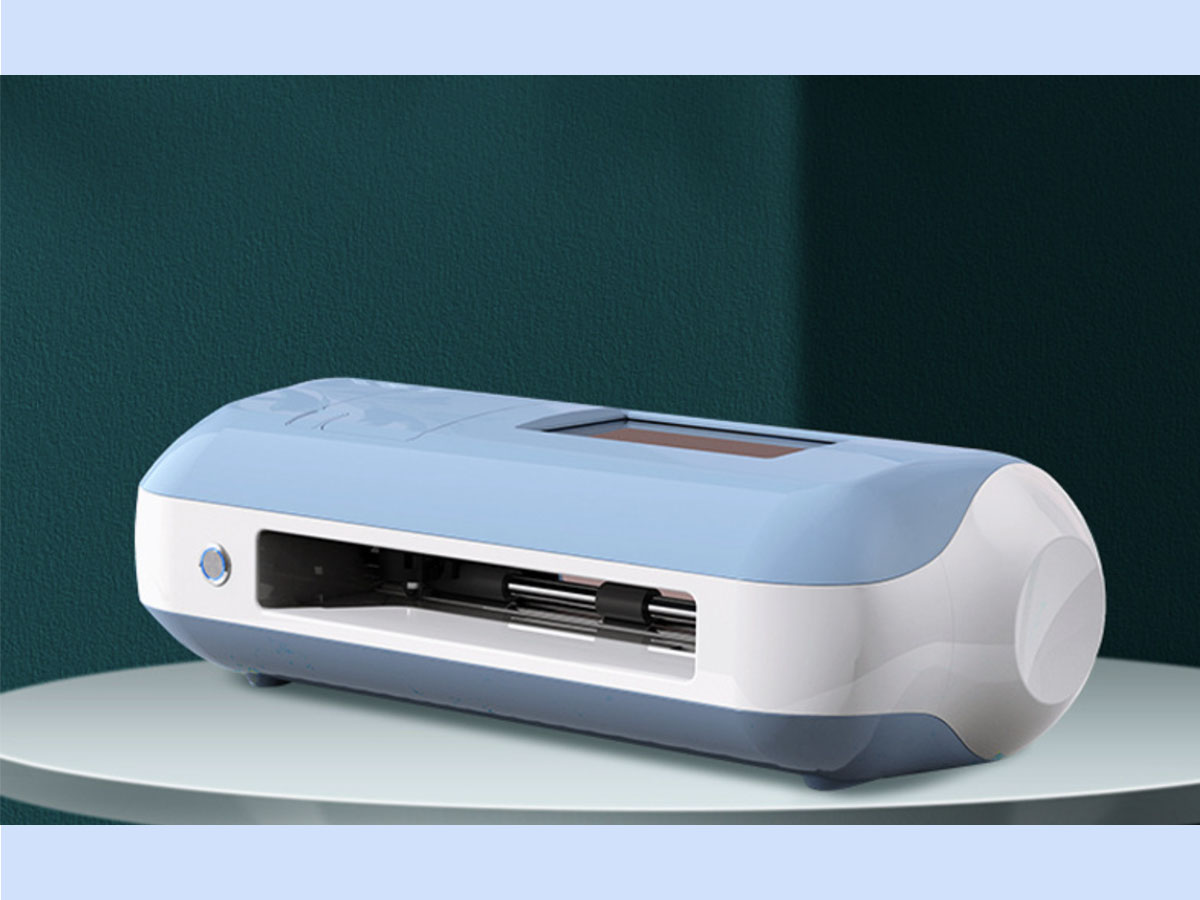

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

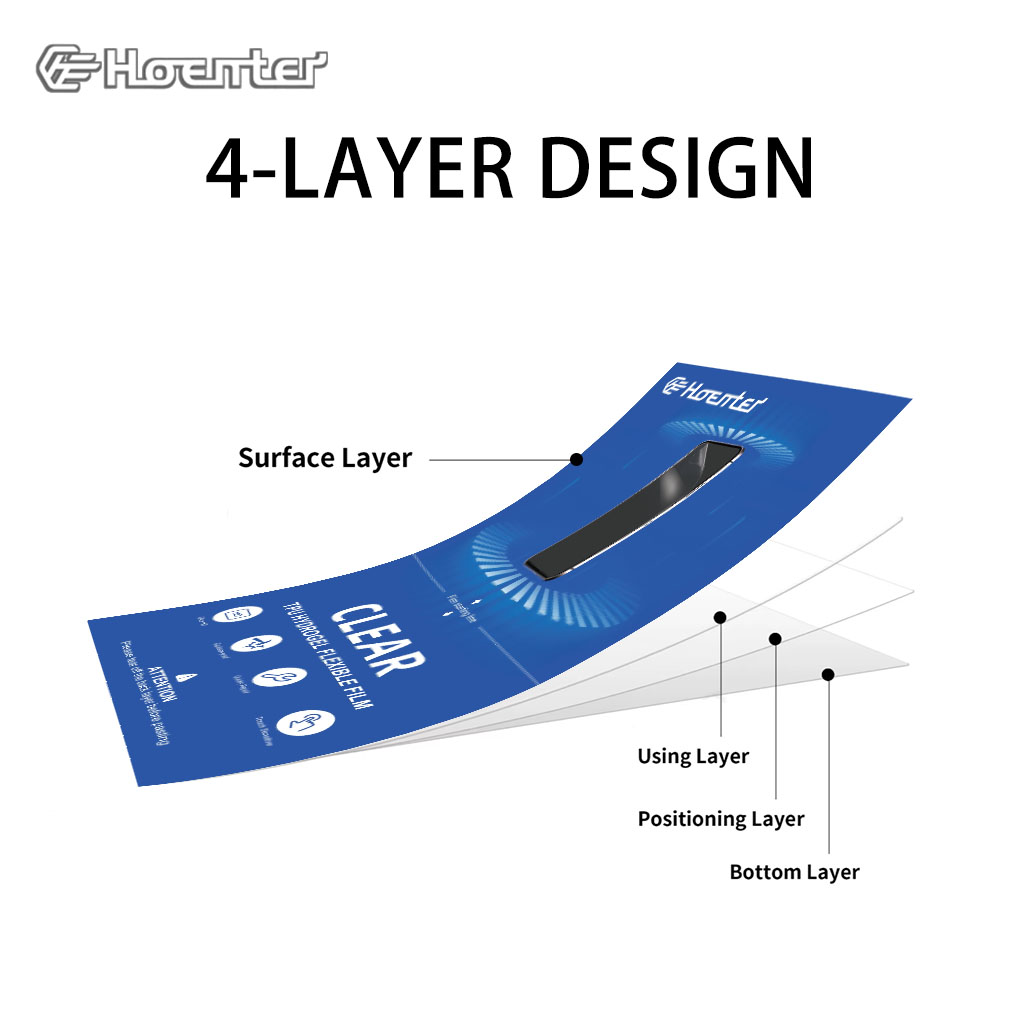

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.