The Environmental Impact of Flexible Hydrogel Films: A Sustainability Perspective

Table of Contents

Extract

Summary

In an era where environmental sustainability is increasingly at the forefront of consumer choices, the materials used in everyday products are under scrutiny. Flexible hydrogel films, a newer entrant in the screen protection market, offer several advantages over traditional materials, including enhanced flexibility and self-healing properties. However, understanding their environmental impact is crucial for consumers and manufacturers who are committed to making eco-friendly choices. This article explores the sustainability aspects of flexible hydrogel films, comparing them with traditional protective materials and evaluating their overall environmental footprint.

Production Processes and Resource Use

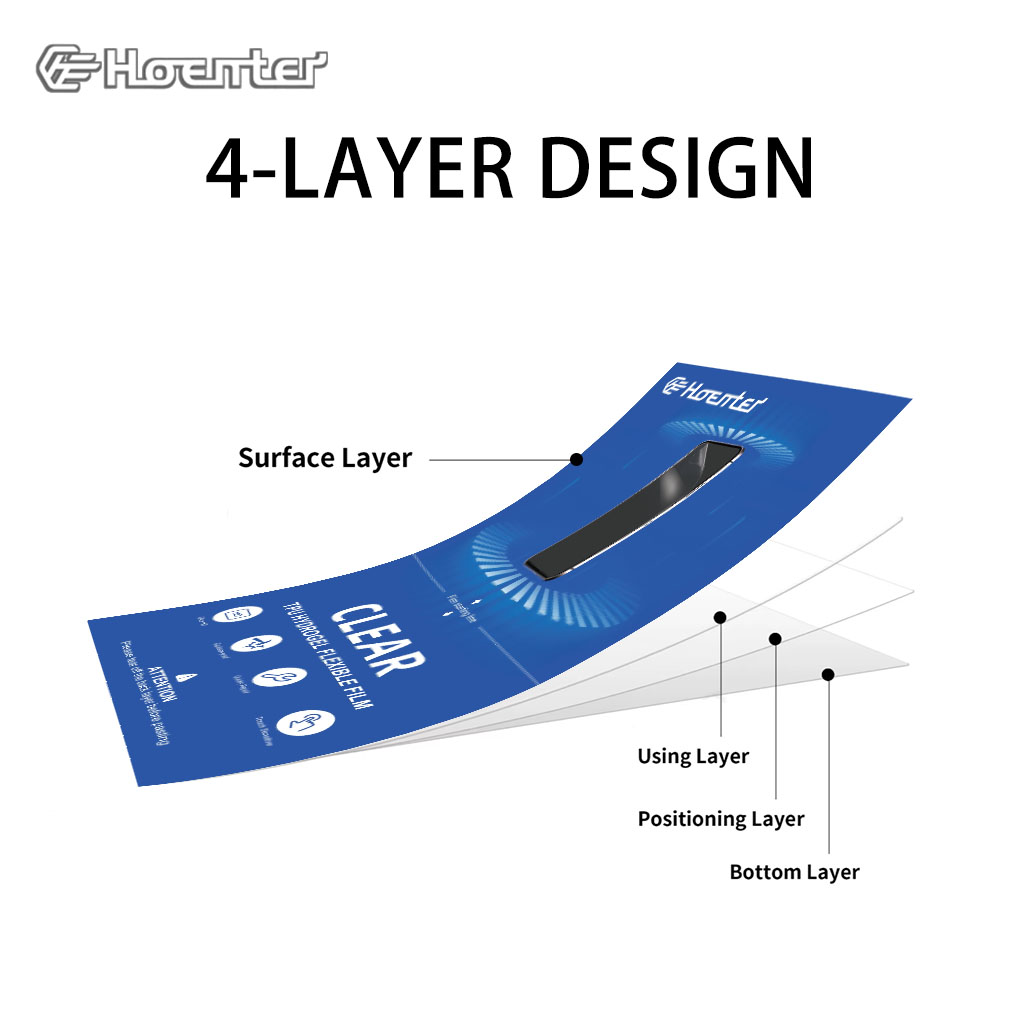

Flexible Hydrogel Films: The production of flexible hydrogel films involves synthesizing a polymer network that can form a gel-like substance. This process generally requires fewer raw materials and less energy compared to the production of tempered glass or some types of plastic films. Hydrogel films are often produced using water-based methods and do not require the high-temperature processes associated with glass manufacturing. This results in a lower carbon footprint during the production phase.

Traditional Protective Films: Tempered glass protectors are made through a high-temperature heating process that strengthens the glass. This process is energy-intensive and contributes significantly to the carbon footprint of the final product. Plastic films, including PET (polyethylene terephthalate) films, are produced using petrochemical derivatives, which involve significant resource extraction and energy consumption. The production of both glass and plastic protectors generally has a higher environmental impact compared to the more energy-efficient processes used for hydrogel films.

Durability and Longevity

Flexible Hydrogel Films: One of the standout features of hydrogel films is their self-healing capability, which extends their usability and lifespan. Minor scratches and dents on hydrogel films can heal over time, maintaining the film’s appearance and effectiveness. This extended lifespan means fewer replacements are needed, reducing overall waste and resource consumption. The durability of hydrogel films helps in minimizing the frequency of replacements and the associated environmental impact of disposing of used protectors.

Traditional Protective Films: Tempered glass protectors, while durable and resistant to heavy impacts, are prone to cracking and shattering upon significant force. When damaged, they often need to be replaced entirely, contributing to more waste. PET plastic films are less durable than glass or hydrogel films and are more prone to scratching and discoloration over time, which can lead to more frequent replacements. The need for constant replacement of plastic films increases the environmental burden associated with their disposal.

End-of-Life Disposal and Recycling

Flexible Hydrogel Films: The end-of-life disposal of hydrogel films poses challenges. While hydrogel materials are not inherently hazardous, they are not yet widely recyclable. The lack of recycling infrastructure for hydrogel films means they often end up in landfills, contributing to environmental waste. However, ongoing research and development are exploring biodegradable options and more sustainable materials to improve the end-of-life impact of hydrogel films.

Traditional Protective Films: Tempered glass protectors are typically recyclable, though the process is not always straightforward and depends on local recycling facilities. Glass can be melted down and repurposed, reducing its environmental impact if properly recycled. PET plastic films, on the other hand, can be recycled, but the recycling process for plastic is less efficient and has a lower recovery rate compared to glass. The environmental impact of plastic waste is substantial, with plastics often contributing to long-term pollution in landfills and oceans.

Sustainable Innovations and Future Trends

Flexible Hydrogel Films: The future of flexible hydrogel films in terms of sustainability looks promising. Manufacturers are exploring biodegradable hydrogel materials that could significantly reduce the environmental impact of these films. Advances in polymer science are paving the way for the development of eco-friendly hydrogels that can break down naturally without leaving harmful residues. Additionally, improvements in production processes aim to further reduce the energy and resources required to manufacture hydrogel films.

Traditional Protective Films: Sustainability efforts in the production of traditional protective films are also evolving. For tempered glass, initiatives to improve recycling processes and the development of closed-loop systems are underway to enhance the sustainability of glass products. In the case of PET plastics, efforts to increase the recyclability of plastic films and the development of alternative materials, such as bioplastics, are important trends. However, these innovations are still in progress and require broader adoption to make a significant environmental impact.

Consumer Considerations and Choices

Flexible Hydrogel Films: For environmentally-conscious consumers, flexible hydrogel films present a more sustainable option compared to traditional screen protectors. Their longer lifespan, lower production energy requirements, and potential for future biodegradable options make them a preferable choice in terms of environmental impact. However, it is crucial for consumers to consider the end-of-life disposal options and support manufacturers that are committed to sustainable practices.

Traditional Protective Films: While traditional protectors like tempered glass and PET plastics have established recycling pathways, their overall environmental impact remains higher due to energy-intensive production processes and frequent replacements. Consumers interested in sustainability should look for brands that emphasize recycling programs and use recycled materials in their products.

Conclusion

The environmental impact of flexible hydrogel films presents a mixed but promising picture. While their production processes are generally more sustainable than those for traditional protective films, and their self-healing properties contribute to reduced waste, there are still challenges related to disposal and recycling. As the screen protection industry continues to evolve, the development of biodegradable hydrogel materials and improved recycling systems will be crucial in enhancing the sustainability of these products.

Consumers and manufacturers alike should stay informed about the environmental implications of their choices and support innovations that prioritize sustainability. By making informed decisions and advocating for environmentally-friendly practices, we can contribute to a more sustainable future for the screen protection industry.

Comments

How to Remove Invisible Shield Screen Protector?

By following these steps, you can confidently remove and replace your Zagg InvisibleShield screen protector, ensuring your device stays protected and looking its best!

Wholesale Self Screen Protector Self Healing

Looking for wholesale self healing flexible screen protectors? We offer premium EPU film with unbeatable protection and a perfect fit. Contact us!

Cutting Transparency Film with Your Cricut: Exploring Materials and Techniques

Transparency film is a versatile material that can add a unique touch to your crafting projects. If you’re wondering whether you can cut transparency film with your Cricut machine, you’re in the right place. This article will guide you through the process, providing insights on how to use your Cricut to cut transparency film effectively. Whether you’re a crafting novice or an experienced DIY enthusiast, understanding how to handle transparency film with your cutting machine can open up new creative possibilities.

How Much Does Phone Screen Repair Cost?

By following this guide, you can navigate the world of phone screen repairs with confidence and make informed decisions that suit your needs and budget.

How to Remove Bubbles from Your Screen Protector: Expert Tips and Tricks

Are you frustrated with those pesky air bubbles ruining the look of your newly applied screen protector? You’re not alone. Many smartphone users struggle with this common issue, but fear not! This comprehensive guide will walk you through various methods to effectively remove bubbles from your screen protector, whether it’s a film or glass type. We’ll cover everything from prevention to troubleshooting, ensuring you achieve a flawless, bubble-free finish that enhances both the appearance and protection of your device.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.