The Future of Hydrogel Screen Protectors: Innovations in Cutting Technology

Table of Contents

Extract

Summary

Known for their flexibility, self-healing properties, and superior fit, hydrogel protectors have quickly become a favorite among consumers and manufacturers alike. However, the success of these protectors is closely tied to advancements in cutting technology. As demand grows, so too does the need for precision, speed, and innovation in the machines that produce these protectors. This article explores the future of hydrogel screen protectors and the cutting-edge technologies that are shaping their production.

The Rise of Hydrogel Screen Protectors

Hydrogel screen protectors have gained popularity due to their unique properties. Unlike traditional tempered glass protectors, hydrogel is a flexible material that can conform to the curves of modern smartphones, providing edge-to-edge protection. It’s also self-healing, meaning minor scratches and dents can disappear over time, keeping the protector looking new for longer.

This material’s popularity has driven manufacturers to seek out new technologies to meet consumer demand. The challenge lies in the fact that hydrogel is a more complex material to cut and shape compared to glass. This complexity has spurred innovations in cutting technology, leading to machines that can deliver precision, efficiency, and versatility.

Precision Cutting: The Key to Quality

One of the most critical aspects of producing hydrogel screen protectors is achieving precise cuts. The material’s flexibility, while beneficial for fitting to various screen shapes, also makes it challenging to handle during the cutting process. Traditional cutting methods, which might work well for tempered glass, often fall short when dealing with hydrogel.

The future of hydrogel screen protector production lies in advancements in precision cutting technology. Laser cutting machines, for instance, are increasingly being adopted due to their ability to deliver highly accurate cuts. These machines use focused laser beams to slice through the hydrogel with minimal material waste and a high degree of accuracy. The result is a perfectly cut screen protector that fits snugly onto any device, from flat screens to those with curved edges.

Moreover, laser cutting technology allows for intricate designs, enabling manufacturers to produce protectors for a wide range of devices, including those with unconventional shapes or designs. This versatility is essential as smartphones and other devices continue to evolve in form and function.

Speed and Efficiency: Meeting Market Demand

As the popularity of hydrogel screen protectors grows, so does the demand for faster production processes. Manufacturers are under pressure to produce high volumes of protectors without compromising on quality. This has led to significant innovations in the speed and efficiency of cutting machines.

Automation is at the forefront of this evolution. Modern cutting machines are increasingly equipped with automated features that reduce the need for manual intervention. For instance, some machines can automatically feed hydrogel sheets into the cutting area, align them precisely, and execute the cutting process with minimal human oversight. This not only speeds up production but also reduces the likelihood of errors that can occur with manual handling.

In addition to automation, advancements in machine learning and artificial intelligence (AI) are playing a role in enhancing efficiency. Cutting machines that incorporate AI can learn from past operations, optimizing cutting patterns and processes over time. This continuous improvement leads to faster cutting cycles and less material waste, ultimately lowering production costs and increasing throughput.

Versatility in Material Handling

The future of hydrogel screen protector cutting technology isn’t just about speed and precision—it’s also about versatility. As new materials and hybrid screen protectors enter the market, cutting machines must be able to adapt. This adaptability is crucial for manufacturers who want to stay competitive by offering the latest products.

One of the most exciting innovations in this area is the development of multi-material cutting machines. These machines are designed to handle a variety of materials, including hydrogel, tempered glass, and even newer hybrid protectors that combine the best properties of both. This versatility allows manufacturers to switch between different materials with ease, enabling them to produce a diverse range of products without needing multiple specialized machines.

Moreover, these machines often come with customizable settings that allow manufacturers to fine-tune the cutting process based on the specific material being used. This ensures that each protector is cut with the optimal settings for that material, resulting in higher quality and better performance for the end product.

Integration with Design Software

Another significant innovation in the production of hydrogel screen protectors is the integration of cutting machines with advanced design software. In the past, creating custom designs or adjusting cutting patterns required manual input, which could be time-consuming and prone to errors. Today, cutting machines are increasingly integrated with CAD (Computer-Aided Design) software, allowing for seamless transition from design to production.

This integration enables manufacturers to quickly create and modify designs based on customer needs or market trends. For example, if a new smartphone model is released, manufacturers can quickly design a screen protector for that model and send the design directly to the cutting machine. The machine then executes the design with precision, ensuring a perfect fit.

In addition, this integration allows for mass customization—a trend that is becoming more popular in the consumer electronics market. Customers can request custom designs, such as protectors with unique cutouts or specific branding, and the machine can produce these designs on demand. This level of customization was previously difficult to achieve but is now becoming a standard feature in the industry.

Sustainability and Waste Reduction

As with many industries, sustainability is becoming a crucial consideration in the production of hydrogel screen protectors. Traditional cutting methods often result in significant material waste, which not only increases production costs but also has a negative environmental impact. However, innovations in cutting technology are helping to address these issues.

One of the most promising developments is the use of optimized cutting algorithms that minimize waste. These algorithms calculate the most efficient way to cut hydrogel sheets, reducing off-cuts and maximizing the use of each sheet. This not only lowers material costs but also reduces the environmental footprint of production.

In addition, some cutting machines are now being designed with energy efficiency in mind. These machines use less power during operation, which not only reduces energy costs but also contributes to a smaller carbon footprint. As sustainability becomes a more significant concern for consumers and businesses alike, these innovations will play a critical role in the future of the industry.

Future Trends: What to Expect

Looking ahead, several trends are likely to shape the future of hydrogel screen protector cutting technology. One of the most significant is the continued advancement of AI and machine learning. As these technologies evolve, cutting machines will become even more efficient, precise, and adaptable. We can expect machines that can predict maintenance needs, optimize production schedules, and even suggest improvements to design and cutting processes.

Another trend is the growing demand for even more sophisticated customization options. As consumers continue to seek out unique and personalized products, the ability to quickly and efficiently produce custom screen protectors will become a key differentiator for manufacturers. Cutting machines that can handle complex designs and rapid design changes will be in high demand.

Finally, sustainability will remain a driving force in the industry. As manufacturers seek to reduce their environmental impact, we can expect to see more innovations aimed at reducing waste, conserving energy, and using eco-friendly materials. Cutting machines that align with these goals will be essential for businesses that want to stay competitive in an increasingly environmentally conscious market.

Conclusion: Embracing the Future of Hydrogel Screen Protectors

The future of hydrogel screen protectors is bright, with innovations in cutting technology leading the way. As precision, efficiency, and versatility continue to improve, manufacturers will be better equipped to meet the growing demand for these protectors. The integration of AI, automation, and advanced design software will further enhance the production process, allowing for faster turnaround times, greater customization, and higher quality products.

As the industry evolves, staying ahead of these trends will be crucial for businesses looking to thrive in the competitive mobile accessory market. By embracing the latest cutting technologies and focusing on sustainability, manufacturers can position themselves for success in the years to come. The continued advancement of hydrogel screen protector cutting machines promises to revolutionize the industry, delivering better products to consumers and driving growth for businesses worldwide.

Comments

Jeep Wrangler JL Navigation GPS Tempered Glass

Our Wrangler JL Navigation Screen Protector offers superior protection for your GPS display.

How to choose the best screen protector factory for your business

Choosing the right screen protector factory is critical to your business and can significantly impact product quality, customer satisfaction, and overall profitability.

Comparing Flexible Hydrogel Films with Traditional Protective Films

The choice between flexible hydrogel films and traditional protective films hinges on your needs for flexibility, durability, and ease of application, with hydrogel films offering a versatile, modern solution and traditional films providing robust protection for flat screens.

Toyota Hilux Navigation GPS Tempered Glass

Our Hilux Navigation Screen Protector offers superior protection for your GPS display.

UV Screen Protector vs Tempered Glass: Which Offers Better Protection for Your Phone?

In the world of mobile phone accessories, screen protectors play a crucial role in safeguarding our devices from scratches, cracks, and everyday wear and tear. Two popular options that often come up in discussions are UV screen protectors and tempered glass screen protectors. But which one is truly superior? This comprehensive guide will delve into the pros and cons of both, helping you make an informed decision for your precious smartphone.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

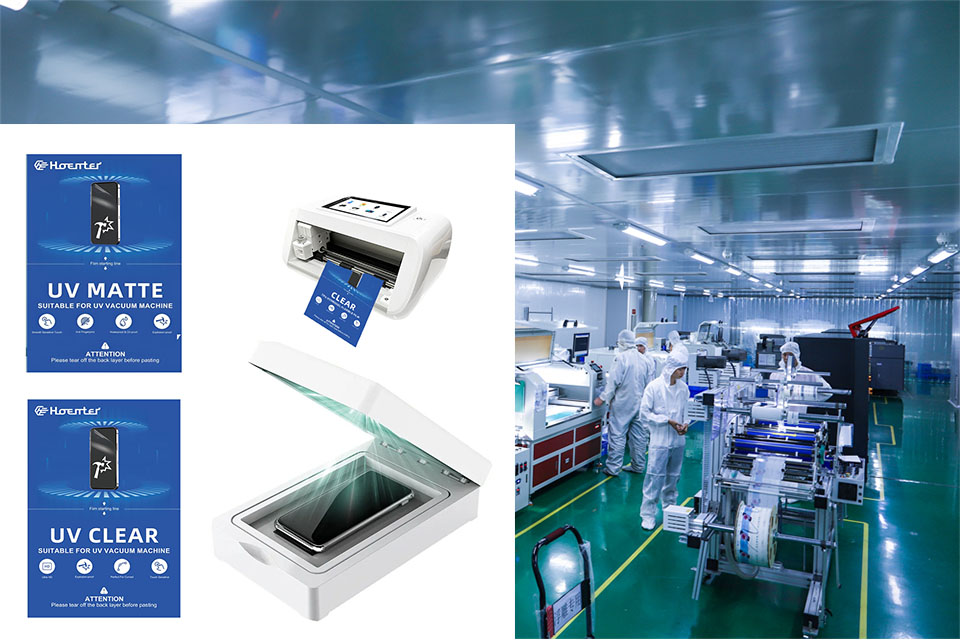

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

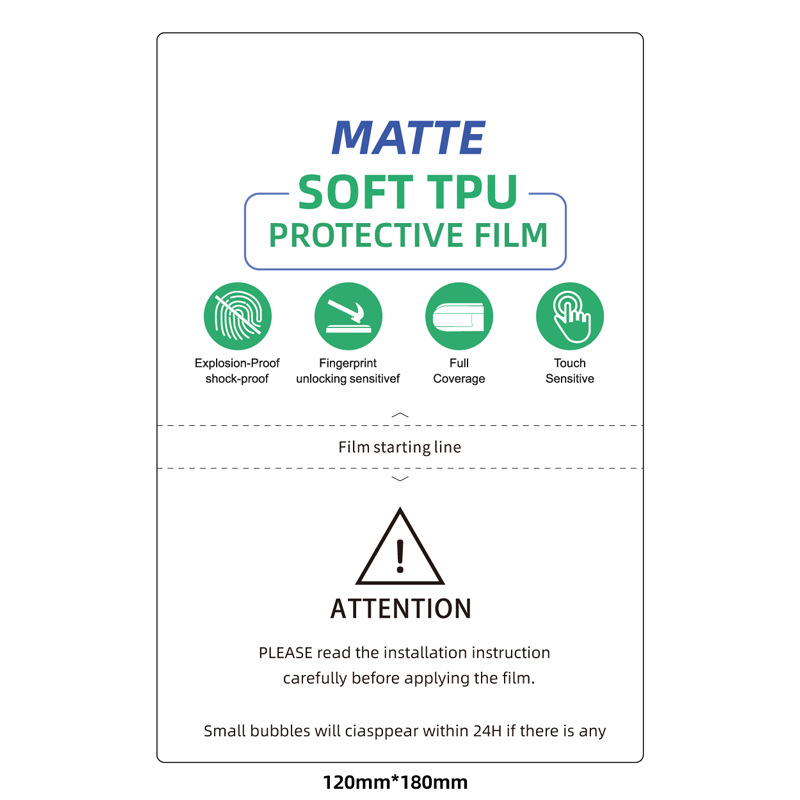

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.