The Latest Innovations in Screen Protector Cutting Machines

Table of Contents

Extract

Historical Background

Initially, screen protectors were primarily pre-cut and offered in standard sizes, which led to challenges regarding compatibility with various devices. The need for customized solutions became evident as mobile devices proliferated, prompting a shift towards more advanced manufacturing techniques.

Emergence of Automation

The advent of automation in the 19th century set the stage for the later innovations in screen protector technology. With the introduction of mechanical automation, businesses began to optimize their production processes, leading to significant changes in how products were manufactured and delivered

. This evolution eventually paved the way for information automation, which targets knowledge work, thereby influencing industries such as screen protector manufacturing.

Technological Advances

The late 20th and early 21st centuries saw rapid advancements in cutting technologies, including the adoption of laser and CNC (Computer Numerical Control) methods. These technologies allowed for precise cutting and shaping of screen protectors tailored to the specific dimensions of various devices

. The development of sophisticated algorithms further enhanced accuracy, ensuring that protectors fit seamlessly over screens with precise cutouts for features such as sensors and cameras.

Materials Science

Parallel to advancements in cutting technology, materials science played a crucial role in the evolution of screen protectors. Early protectors were often made from less durable materials, leading to a demand for stronger, more resilient options. Today’s custom-cut screen protectors utilize advanced materials such as tempered glass and specialized polymer blends, engineered to offer high levels of scratch resistance and impact protection

.

The Modern Era

The latest innovations have brought about cutting machines capable of customizing protectors for thousands of device models, such as LENSUN’s Customizpro+

. These machines incorporate cloud databases for easy updates and a user-friendly interface, highlighting a significant shift towards technology-enabled solutions in the industry. As consumer expectations for device protection evolve, the screen protector cutting machine continues to adapt, reflecting broader trends in technology and manufacturing that emphasize personalization and efficiency.

Latest Innovations

Recent advancements in screen protector cutting machines have leveraged evolving technologies to enhance performance, efficiency, and user experience. These innovations have been propelled by the increasing demand for precision and customization in the screen protection market.

Automation and Real-Time Monitoring

One significant innovation is the integration of automation technologies into screen protector cutting machines. This has led to enhanced productivity, with companies reporting utilization increases of 10-20% by adopting automated systems

. Moreover, real-time monitoring capabilities are being implemented to ensure cutting accuracy and quality control. Operators can track cutting progress and promptly detect deviations from specifications, which helps maintain high standards of production.

Data-Driven Insights

The use of data analytics in optimizing cutting parameters such as speed, feed rate, and depth has emerged as a critical advancement. By analyzing operational data, manufacturers can fine-tune their processes to achieve precise results while minimizing tool wear and heat buildup

. This shift towards data-driven decision-making reflects a broader trend in industries adopting disruptive models, where inefficiencies are identified and addressed through innovative approaches.

Human-Centered Design

Furthermore, the development of screen protector cutting machines is increasingly influenced by human-centered design principles. As the industry learns from past missteps in technology deployment, there is a growing emphasis on creating systems that prioritize user experience and operational efficiency. This focus aims to enhance productivity while ensuring that machine operators have the tools necessary to make informed decisions about the cutting process

.

Future Prospects

The future of screen protector cutting machines is closely linked to advancements in material science, automation, and digital technology. As innovations continue to emerge, manufacturers are expected to enhance the performance, reliability, and efficiency of these machines significantly. The integration of smart materials and intelligent design principles could lead to breakthroughs in how screen protectors are produced, tailored, and applied, potentially driving the market towards greater economic success and technical excellence

.

Technological Integration

The convergence of automation technologies, artificial intelligence (AI), and machine learning is anticipated to transform the production processes of screen protector cutting machines. These advancements will likely result in improved productivity, accuracy, and the ability to create customized solutions for diverse consumer needs

. For example, AI could be utilized to optimize cutting patterns and materials, reducing waste and increasing efficiency during manufacturing. As a result, companies deploying such technologies may realize substantial gains, positioning themselves competitively in an evolving market landscape.

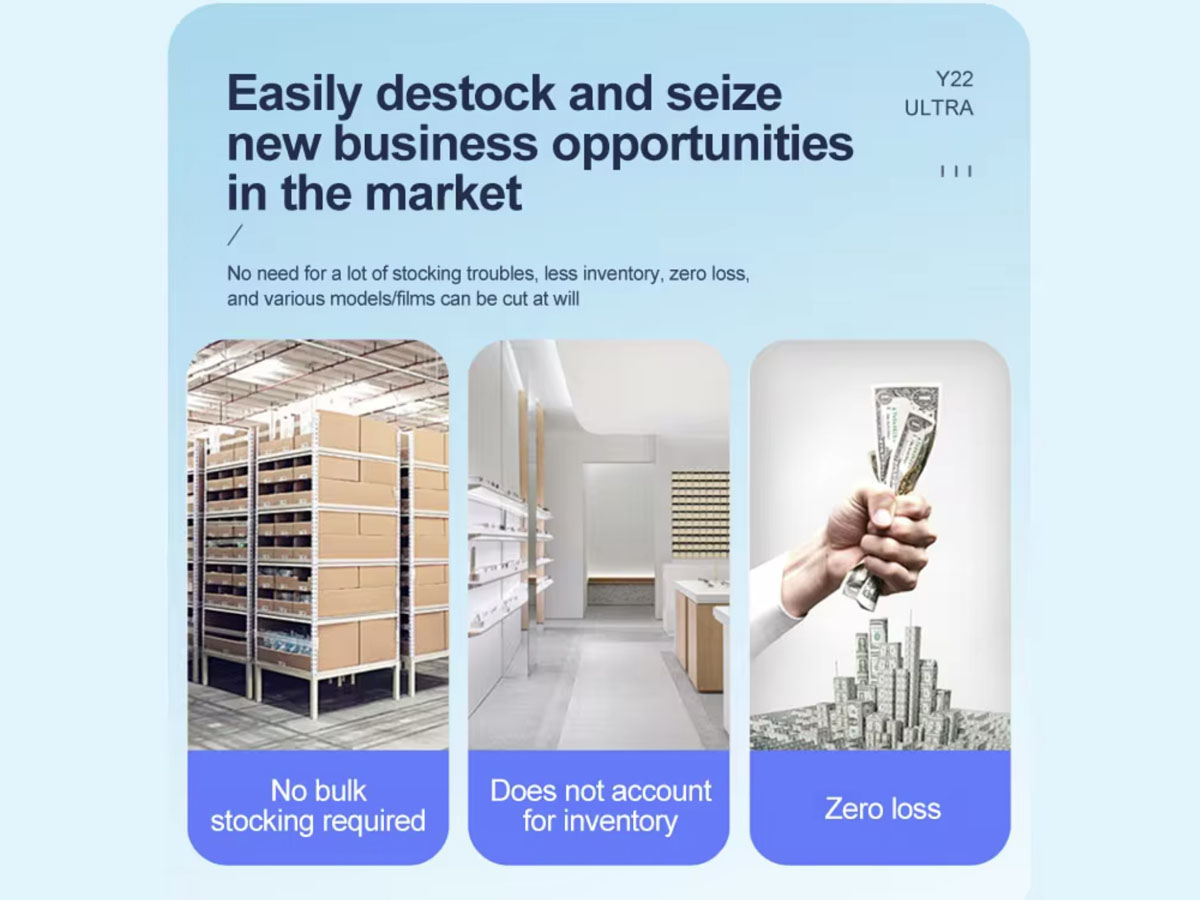

Market Trends and Consumer Behavior

As consumer expectations evolve, there is an increasing demand for personalized and high-quality screen protectors. Innovations in cutting machines will be crucial for addressing this demand, enabling rapid prototyping and production of tailored products. Additionally, the growing reliance on digital platforms for e-commerce and customized services will open new channels for marketing and distribution

. This trend indicates a broader shift towards decentralized manufacturing, where smaller enterprises can compete effectively with larger players by leveraging advanced cutting technology.

Sustainability and Material Advances

The future of screen protector cutting machines will also likely focus on sustainability, with advancements in eco-friendly materials and processes. As consumers become more environmentally conscious, manufacturers will be encouraged to explore biodegradable or recycled materials for screen protectors. This shift may catalyze new innovations in cutting technologies that accommodate these materials without compromising quality or efficiency

.

Challenges and Adaptations

Despite these promising advancements, challenges remain. The rapid pace of technological change necessitates that companies adapt quickly to stay relevant. Organizations will need to invest in research and development to harness these innovations effectively, which can be daunting given the complexities involved in integrating new technologies

. Moreover, market volatility and shifting labor dynamics may impact how these machines are designed and operated in the coming years.

Features of Modern Machines

Modern screen protector cutting machines are at the forefront of technological innovation, incorporating various advanced features to enhance productivity and precision in manufacturing.

Automation and Efficiency

The introduction of automation in cutting machines significantly reduces the need for human intervention, thereby increasing efficiency, precision, and productivity in operations. The evolution of Computer Numerical Control (CNC) machines since the 1940s has led to highly sophisticated setups that integrate multiple functions, such as drilling and milling, within a single cell.

As automation continues to rise, a substantial percentage of employees believe that they could save considerable time annually through these advancements, indicating a trend towards more automated solutions in manufacturing settings.

Precision Engineering

Modern machines are designed to handle ultra-precision and micro machining, achieving surface roughness at the nanometric scale and intricate features at the micrometer level. This capability is particularly vital for producing high-precision components and products that require improved functionality and performance.

The smart precision and micro-manufacturing approach is seen as the way forward, emphasizing proactive and advanced techniques that respond to the ever-increasing demand for quality.

Adaptability and Flexibility

The most advanced cutting machines possess the capability to make real-time adjustments, enabling seamless transitions between different product types without halting production to change programs or reconfigure tooling. Technologies like RFID tags are used to adjust component shapes on-the-fly, showcasing the shift towards “lights out” production environments where manufacturing is conducted entirely automatically.

This adaptability not only improves quality by minimizing errors but also reduces variability and cuts down manufacturing costs.

Advanced Material Handling

Incorporating new materials and coatings into screen protection is essential for maintaining the integrity and performance of electronic devices. Modern machines are designed to work with cutting-edge materials, such as transparent coatings and graphene, which elevate user experiences by ensuring optimal clarity and touch sensitivity while providing essential protection.

The integration of nanotechnology has enabled the production of ultra-thin, transparent nano glass screen protectors that offer superior strength and scratch resistance.

Market Trends

Competitive Landscape

The competitive landscape of the screen protector market is becoming increasingly dynamic. Companies that effectively harness data and analytics can gain a substantial edge by optimizing their decision-making processes and operational efficiencies. However, many organizations are only capturing a fraction of the potential value available through these technologies

. The ability to innovate and adapt in this rapidly changing environment will be crucial for companies aiming to maintain or enhance their market positions.

Growing Demand for Customization

The screen protector market is witnessing a significant shift towards customization as devices evolve with innovative form factors, including curved, foldable, and wrap-around displays. Manufacturers are faced with the challenge of developing tailored solutions that offer optimal protection without compromising functionality or aesthetics, necessitating ongoing research and development efforts

. As consumers increasingly seek personalized products, this trend is expected to drive innovation in screen protector manufacturing.

Sustainability Initiatives

With rising environmental awareness, the screen protector industry is embracing sustainable manufacturing practices. Companies are prioritizing the use of recyclable materials, reducing waste, and adopting eco-friendly production processes to minimize their ecological footprint. This shift not only caters to the growing consumer demand for sustainable products but also aligns with broader corporate responsibility goals

.

Advancements in Technology

Technological advancements are shaping the future of screen protectors, with innovations such as nanotechnology, self-healing materials, and holographic integration emerging as key trends. These breakthroughs are transforming traditional manufacturing processes and enhancing the durability and effectiveness of screen protectors

. The integration of robotics and automation in production lines is also streamlining operations, enabling faster production times while maintaining high-quality standards.

Market Dynamics

Approximately 12% of the global goods trade is conducted via international e-commerce, significantly impacting the screen protector market. Digital platforms like Alibaba and Amazon facilitate a more global labor market, allowing small and medium-sized enterprises to compete effectively with larger incumbents. This democratization of access is expected to drive further growth in the sector, as businesses leverage digital channels to reach a wider audience

.

Applications

Overview of Screen Protector Cutting Machines

Screen protector cutting machines have become essential tools in various industries due to their ability to provide customized solutions for mobile devices. These machines enable the precise cutting of screen protectors that fit a wide array of devices, from smartphones to tablets, enhancing their durability and usability.

Cloud Computing Integration

In recent developments, cloud computing has played a significant role in the functionality of screen protector cutting machines. The integration of cloud applications allows for enhanced monitoring and troubleshooting of these machines, ensuring optimal performance and reduced downtime. Tools such as AWS CloudWatch and New Relic facilitate real-time performance tracking, while automation scripts streamline issue resolution processes

. This enables manufacturers to maintain high availability and performance of their cutting machines, ultimately improving product quality.

Software Applications

There are various software applications tailored for screen protector cutting machines that leverage cloud technology. For instance, applications like Google Docs enable easy access and collaboration on design templates for screen protectors, allowing businesses to share and modify designs efficiently

. Additionally, platforms such as Pixlr provide tools for graphic design, helping users create and customize screen protector layouts before cutting.

Automation and CI/CD Practices

The implementation of Continuous Integration/Continuous Deployment (CI/CD) practices is revolutionizing the production process for screen protectors. By using tools such as Jenkins and GitLab CI/CD, manufacturers can automate their build, test, and deployment procedures, enhancing the efficiency and reliability of the cutting machine’s operation in cloud environments

. This level of automation ensures that updates to software controlling the cutting machines are deployed smoothly, reducing the risk of errors and increasing production speed.

Customization and Integration Tools

To meet the diverse needs of customers, integration tools such as Integration Platform as a Service (iPaaS) and Robotic Process Automation (RPA) software are being employed. iPaaS solutions allow for the creation of API-based integrations, facilitating seamless communication between the cutting machines and other applications used in business operations

. On the other hand, RPA tools enable integration with applications that lack APIs, thereby broadening the range of compatible software solutions.

Future Innovations

Looking ahead, the proliferation of handheld digital devices is expected to drive further innovations in screen protector cutting technology. As more consumers rely on mobile devices, the demand for high-quality, customized screen protectors is anticipated to grow, prompting advancements in cutting machine technology and software applications

. The continued development of augmented reality (AR) and virtual reality (VR) tools may also enhance design capabilities, allowing for interactive and innovative user experiences in the customization process.

Challenges and Limitations

The integration of AI and automation in various sectors presents several challenges and limitations that must be addressed to optimize their potential.

Technical Challenges

One significant barrier is the technical limitations associated with AI algorithms. These include the need for massive amounts of training data and difficulties in generalizing algorithms across various use cases. Despite recent innovations aimed at mitigating these issues, the need for robust data remains a critical concern

. Additionally, explaining the decisions made by machine learning algorithms poses challenges, particularly in high-stakes areas such as financial lending and legal applications. This difficulty in transparency raises questions about accountability and ethical use of technology.

Workforce Adaptation

As automation progresses, the workforce will need to adapt to changing skill requirements. The demand for advanced technological skills, such as programming, is expected to grow rapidly, while physical and manual skills will decline but still dominate the workforce landscape in many countries by 2030

. This shift necessitates substantial training and retraining efforts for both mid-career workers and new generations, which presents a logistical challenge for educational and corporate institutions.

Economic Implications

Moreover, the economic impacts of automation and AI are complex. While these technologies can drive productivity growth, they may also lead to increased unemployment in sectors heavily reliant on rote tasks, such as transportation and food service

. This scenario creates a pressing need for policymakers, businesses, and educational institutions to collaborate on developing effective strategies for workforce transitions and addressing potential job dislocation.

Ethical Concerns

Ethical considerations surrounding the deployment of AI and automation also remain a critical issue. Bias in training data and algorithms, along with concerns over data privacy and malicious use, complicate the landscape. These ethical challenges necessitate comprehensive frameworks to ensure responsible usage of technology

. Furthermore, as Stephen Downes notes, individual empowerment may shift the balance of dependence away from centralized services, raising concerns about how such changes will affect society and economic structures.

Comments

DONGFENG T5 EVO 2023 Navigator Tempered Glass

Get the best 2023 DONGFENG T5 EVO Tempered Glass screen protector. Ultra-clear and designed to maintain the touch sensitivity of your navigation display.

Honda Acura Integra 2023 Navigation Tempered Glass

Get the best 2023 Integra Tempered Glass screen protector. Ultra-clear and designed to maintain the touch sensitivity of your navigation display.

Is Hydrogel Good for Phones?

By understanding the differences between hydrogel and tempered glass screen protectors, you can make an informed decision that best suits your needs.

What Is a Hydrogel Cell Phone Screen Protector?

By understanding the differences between hydrogel and tempered glass screen protectors, you can make an informed decision that best suits your mobile phone protection needs.

Are Hydrogel Screen Protectors Any Good?

Both hydrogel and tempered glass screen protectors have their merits. Your choice should depend on your specific needs and preferences.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

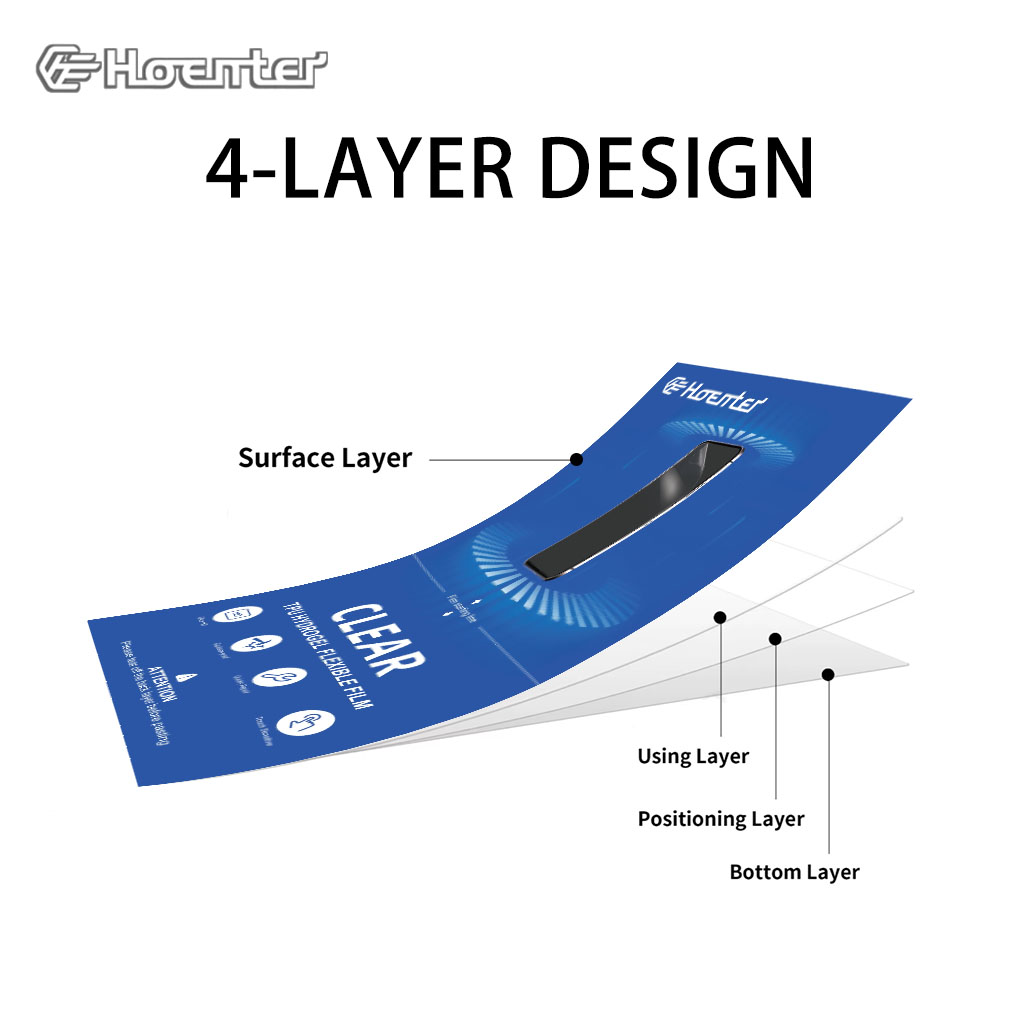

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.