The Manufacturing Process- Inside a Screen Protector Factory

Table of Contents

Extract

Materials Used

The manufacturing of screen protectors involves a variety of materials, each contributing to the final product’s durability and functionality.

Main Materials

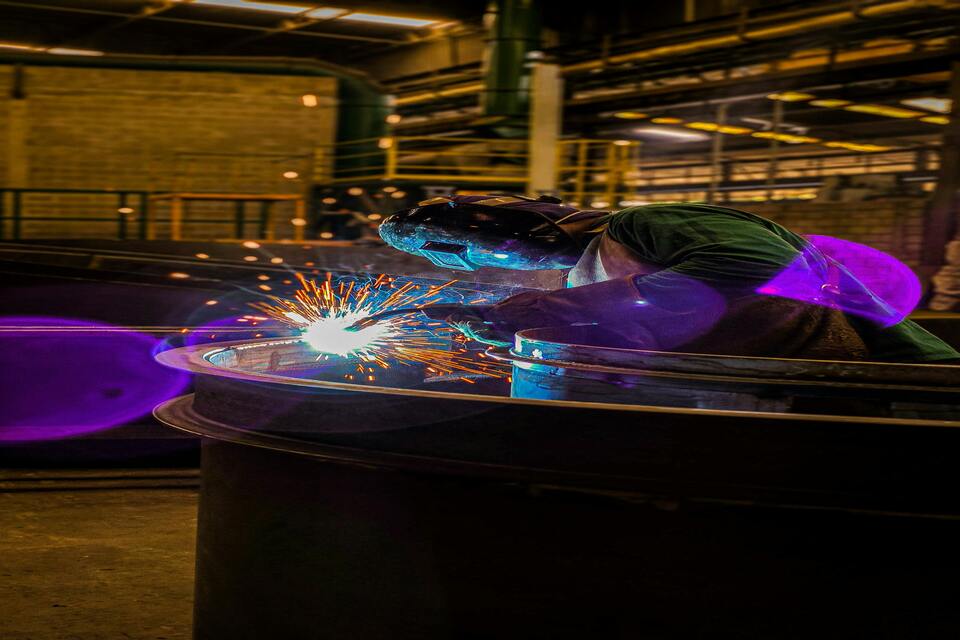

Glass

One of the most common materials used for screen protectors is tempered glass. This type of glass is subjected to a specific manufacturing process where it is heated to high temperatures and then rapidly cooled, resulting in increased strength—up to five times stronger than standard glass

. In addition to its inherent toughness, tempered glass may also include aluminosilicate or other compounds to enhance its protective properties.

Plastic

Plastic screen protectors are also prevalent, made from materials like polycarbonate and polyurethane. These materials are molded through injection processes, where the plastic is heated and poured into a mold to form the desired shape. They are typically lighter and less expensive than glass alternatives but may not offer the same level of scratch resistance

.

Coatings

In addition to the base materials, various coatings are applied to screen protectors to improve their functionality. These coatings may provide features such as anti-glare, anti-fingerprint, or self-cleaning properties. For instance, some advanced coatings allow the protector to repel dirt and grease, making maintenance easier

.

Specialty Materials

Recent innovations have introduced self-healing materials that can repair minor scratches autonomously. These materials often utilize microcapsules filled with a healing agent that, when damaged, release the substance to mend the scratch. This capability significantly enhances the lifespan and aesthetic appeal of screen protectors, making them particularly appealing for use in devices exposed to daily wear and tear

.

Manufacturing Process

The manufacturing process of screen protectors involves several crucial stages, from preparing the production line to implementing quality control measures, all while emphasizing environmental responsibility.

Preparing the Production Line

Before crafting the first screen protector, manufacturers must prepare a well-organized production line. This preparation entails selecting high-quality materials and acquiring advanced equipment to ensure efficiency and effectiveness in production. The application of anti-glare coatings is a key feature of this phase; these coatings minimize reflections and fingerprint smudges, enhancing the user’s viewing experience, especially in bright environments

. Additionally, oleophobic coatings are applied to repel oils and fingerprints, allowing for easier cleaning and a consistently clear display. During this stage, strict quality control is maintained to ensure uniformity in the application of protective layers. The precise application and curing processes are essential for achieving the desired functionality and longevity of the screen protectors. Manufacturers invest in specialized coating machines to ensure that these protective layers are effectively applied, resulting in products that not only safeguard against physical damage but also improve user experience.

Quality Control Measures

Quality control (QC) is a vital aspect of the screen protector manufacturing process. Effective QC involves regular inspections throughout production, providing a comprehensive view of the product’s evolution. This proactive approach helps to identify potential flaws early, thereby reducing the likelihood of issues in the final product

. The implementation of traceability measures—where products are labeled with identifying information—enables manufacturers to pinpoint where errors may occur during production, facilitating swift corrective actions. Embedding a culture of quality within the organization is crucial for maintaining high standards. This can be achieved through structured training programs for employees, simulating real-world scenarios to prepare them for identifying and addressing quality control issues. Regular inspections should occur at every stage of production, rather than only at the end, which significantly enhances the chances of detecting problems early and reduces overall costs.

Continuous Improvement

The integration of data analytics through Statistical Process Control allows manufacturers to continuously enhance quality assurance. By evaluating production data, manufacturers can better manage processes, ensure consistent product quality, and identify potential problems before they arise

. This systematic approach leads to improved process control, cost reductions, and higher customer satisfaction, essential for maintaining a competitive edge in the market. Through these meticulous processes, screen protector manufacturers strive not only for functionality but also for environmental sustainability, embracing recyclable materials and sustainable practices to minimize their ecological impact.

Packaging

Protective and Retail Packaging

Screen protectors require careful packaging to ensure their safety during transit. Manufacturers typically use sturdy materials such as cardboard boxes and bubble wrap to protect the products from impacts and scratches

. Retail packaging, particularly for screen protectors sold in physical stores, is designed to be visually appealing. Eye-catching graphics and clear product information help consumers make informed decisions, enhancing the overall shopping experience.

Environmental Considerations

The manufacturing process of screen protectors involves significant environmental considerations, particularly in relation to materials used and the sustainability practices adopted. One notable material is glass, which is 100% recyclable and can be reused infinitely without loss in quality or purity

. Utilizing recycled glass not only conserves raw materials but also reduces energy consumption by 30% and lowers CO2 emissions by up to 50% compared to producing virgin glass.

International Shipping and Distribution

Effective international shipping strategies are crucial for screen protector manufacturers who distribute products globally. Collaborating with reliable logistics companies ensures timely and cost-efficient delivery to customers around the world

. Moreover, screen protectors are available through various retail channels, including online marketplaces, electronics stores, and specialized accessory retailers, allowing manufacturers to cater to a broad customer base.

Quality Assurance and Compliance

To maintain product integrity during shipping, manufacturers adhere to established testing standards such as ASTM D5276-98, which focuses on packaging performance during transit

. Compliance with these standards not only safeguards the products but also underscores a commitment to quality and reliability in the competitive marketplace.

Supply Chain and Distribution

Distribution Channels

Screen protectors are distributed through various retail channels, including online marketplaces, electronics stores, and specialized accessory retailers. This diversified approach allows manufacturers to reach a broad customer base, catering to different market segments. Additionally, many companies, including ND Group, adopt a direct-to-consumer sales model via their websites. This model fosters closer customer relationships and enables companies to collect valuable feedback for continuous improvement

.

Overview of Supply Chain Management

The supply chain for screen protector manufacturing encompasses a series of interconnected processes that ensure efficient production and distribution of the final product. Key components include procurement of raw materials, production technology, and effective logistics management. ND Group, for instance, integrates design, production, and CNC services, highlighting the importance of a cohesive approach to supply chain management in achieving operational efficiency and cost-effectiveness

.

Procurement of Raw Materials

The selection of raw materials significantly influences production costs and product quality. Manufacturers typically source materials such as tempered glass, polyethylene terephthalate (PET), and thermoplastic polyurethane (TPU) to meet varying consumer preferences and price points. The mid-range price segment, particularly for TPU-based screen protectors, is projected to experience robust growth, driven by rising disposable incomes and demand for affordable protective accessories

. ND Group not only supplies these materials but also provides spare parts and comprehensive training for staff, which enhances the overall efficiency of the manufacturing process.

Logistics and Transport

Logistical planning is essential for the seamless transport of machinery and materials to and from manufacturing sites. ND Group emphasizes proper packaging and safety measures for their production equipment, ensuring that machines are secured during transit and protected from damage. Their logistics strategy includes layout drawings for container shipments, ensuring optimal space utilization for transporting machinery and parts

.

Quality Control and Training

Quality assurance is intertwined with supply chain management in the manufacturing process. Effective quality control strategies, including risk management and employee training, play crucial roles in maintaining product standards and minimizing defects

. ND Group focuses on staff training across production, operation, and sales, which not only enhances product quality but also improves overall customer satisfaction.

Environmental Considerations

Modern manufacturers are increasingly adopting eco-conscious initiatives within their supply chains. This includes the use of sustainable packaging materials and carbon-neutral shipping options, reflecting a commitment to reducing the environmental impact of their operations. Such practices are vital for aligning with consumer expectations and promoting a responsible manufacturing ethos

.

Recent Technological Advancements

Overview of Innovations

In recent years, the screen protector industry has witnessed significant technological advancements driven by the need for improved durability, functionality, and aesthetics. Manufacturers are increasingly leveraging innovative materials and manufacturing techniques to create high-performance screen protectors that cater to the evolving demands of consumers

.

Nanotechnology in Screen Protection

One of the most groundbreaking developments is the application of nanotechnology in screen protectors. Nanocomposite materials, such as graphene and carbon nanotubes, have emerged as frontrunners in enhancing screen protection. These materials offer exceptional strength, flexibility, and transparency, providing enhanced scratch resistance and impact protection. Some even possess self-healing properties, which allow minor scratches to repair themselves over time

.

Benefits of Nano Screen Protectors

Nano screen protectors are designed to address common issues like scratches, fingerprints, and smudges. The nanometer-sized particles fill in microscopic imperfections on the device’s screen, creating a smooth surface that is resistant to dirt and moisture. This technology not only enhances protection but also improves user experience by reducing glare and eye strain through advanced light diffusion techniques

.

Emerging Materials and Techniques

The market has also seen a shift toward the development of flexible and transparent conductive materials that align with the rise of foldable devices. This transition aims to ensure optimal touch responsiveness while maintaining protective qualities. Traditional materials like tempered glass and PET film are still prevalent, but the demand for innovative solutions continues to grow, prompting researchers and manufacturers to explore new frontiers

.

Future Trends

As consumer preferences evolve towards eco-conscious choices and heightened privacy, the future of screen protector technology looks promising. Innovations such as self-repairing materials and advanced privacy screens are on the horizon, aimed at further enhancing the functionality and aesthetic appeal of protective accessories

.

The Manufacturing Process: Inside a Screen Protector Factory

The manufacturing process of screen protectors is a complex and specialized endeavor that plays a crucial role in the smartphone and electronics accessory market. With the global increase in smartphone usage, the demand for effective screen protection has surged, making screen protectors a significant commodity in consumer electronics. These protective layers not only safeguard devices from scratches and impacts but also enhance user experience through features like anti-glare and anti-fingerprint coatings, thus highlighting their notable importance in device longevity and functionality. At the heart of screen protector manufacturing are key materials, including tempered glass and various plastics, each selected for their durability and protective qualities. Innovations such as self-healing materials and advanced coatings have further enhanced the functionality of these products, catering to consumer demands for high-performance and eco-friendly options. Manufacturers have also adopted rigorous quality control measures throughout production to ensure consistent product standards, thereby minimizing defects and fostering customer satisfaction. The industry faces ongoing challenges, including environmental sustainability concerns related to material sourcing and production practices. Many manufacturers are actively working to mitigate their ecological footprint by using recyclable materials and sustainable packaging solutions. Additionally, the integration of data analytics in quality assurance processes allows for continuous improvement, ensuring that manufacturers remain competitive while meeting the evolving needs of consumers. In summary, the manufacturing process of screen protectors encompasses a blend of material science, technological innovation, and environmental responsibility. As advancements continue to emerge, the industry is poised for further growth, navigating controversies around sustainability while striving to provide effective protection for an ever-evolving array of devices.

Comments

How to Repair a Cracked Phone Screen

You should feel empowered to tackle a cracked phone screen with confidence.

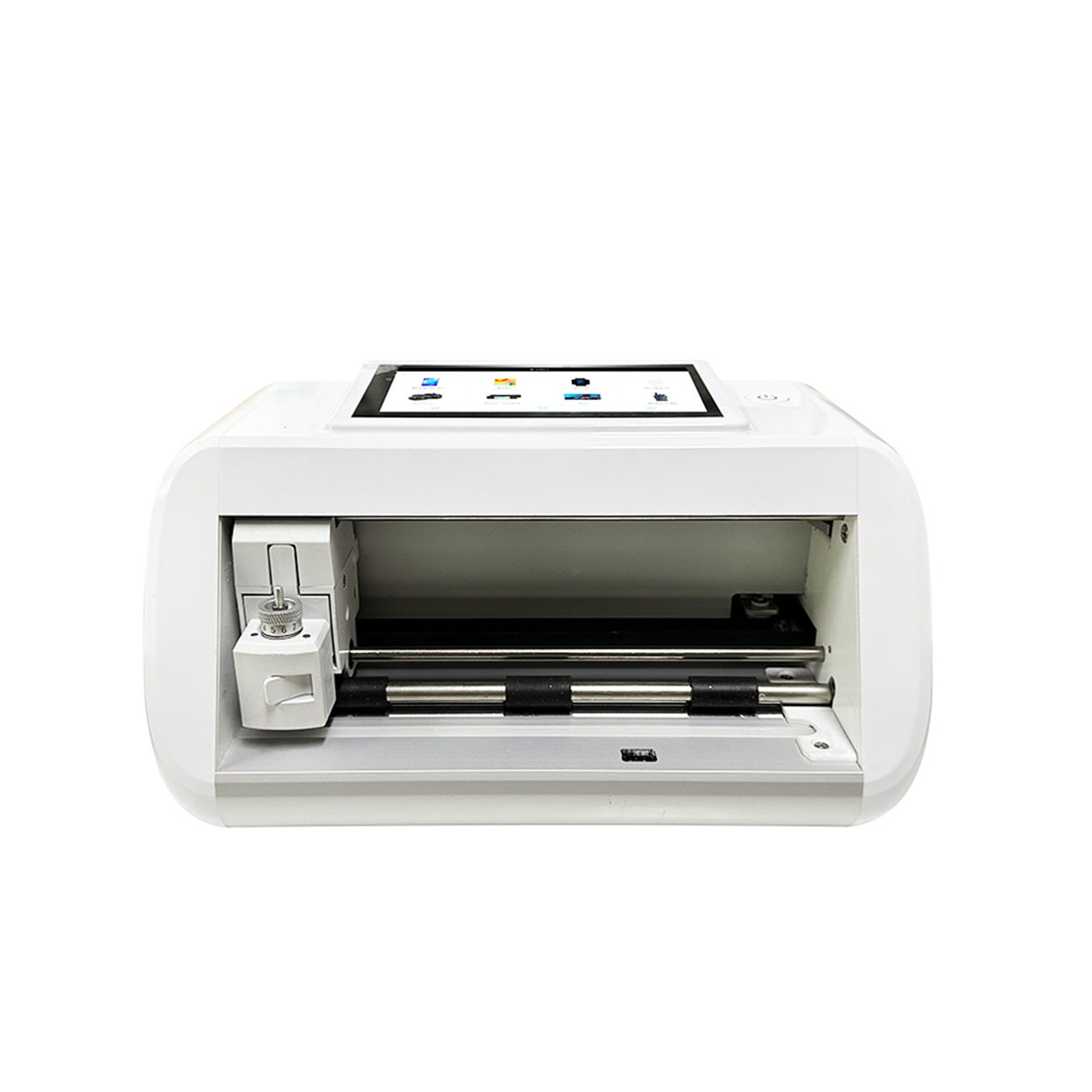

Mini Screen Protector Cutting Machine Manufacturer

Home mini screen protector cutting machine Email What’sApp Product Parameters CONTROL:APP control / Bluetooth LCD TOUCH SCREEN : 5.5″ HD

Tempered Glass or Hydrogel Screen Protector

Choosing between a tempered glass and hydrogel screen protector ultimately depends on your individual needs and preferences.

UV Light Curing Machine For Phone Protector

Quick Curing: Cures the screen protector in less than 5 minutes.

Superior Protection: Offers 3H hardness, explosion-proof, and drop-proof protection.

Disinfection: UV light sterilizes the phone, providing added hygiene.

Simple Process: Easy to use with minimal effort and a perfect finish every time.

With its advanced features, ease of use, and superior protective qualities, this UV Light Curing Mobile Phone Film Machine is the ultimate solution for ensuring your mobile phone remains safe, clean, and scratch-free!

Can a Cracked Screen Protector Damage Your Phone?

By taking these steps, you can prevent long-term damage to your phone and ensure it remains in top condition.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.