Top 5 Benefits of Using a Screen Film Cutting Machine for Your Store

Table of Contents

Summary

These machines cater to a wide range of devices, including smart- phones, tablets, laptops, and smartwatches, by providing automated measurements and high-quality materials to ensure optimal protection and a perfect fit. The ability to produce custom designs and rapid production capabilities have made screen film cutting machines invaluable tools for both tech enthusiasts and retail businesses.

One of the primary benefits of screen film cutting machines is their speed and efficiency. The automated cutting process allows for quick and precise production of screen protectors, eliminating rough edges and imperfections. This efficiency

not only meets high market demands but also enhances customer satisfaction by providing timely service. Furthermore, these machines are equipped with advanced features such as safety sensors and automatic material detection, which ensure user protection and reduce material wastage.

The versatility of screen film cutting machines extends to their ability to accom- modate various screen sizes and shapes, thanks to adjustable settings and advanced software. This flexibility enables businesses to offer a diverse range of products, from standard screen protectors to personalized designs featuring logos or patterns. This level of customization is particularly beneficial for businesses looking to enhance their branding and offer unique options to consumers.

In addition to operational benefits, screen film cutting machines also stream- line business operations by simplifying SKU management, reducing inventory chal- lenges, and optimizing stock levels. The implementation of these machines can lead to substantial cost savings and scalability through over-the-air updates. By integrating these machines into their operations, businesses can improve efficiency, reduce manual labor, and ultimately increase profitability while meeting the diverse needs of their customers.

Overview of Screen Film Cutting Machines

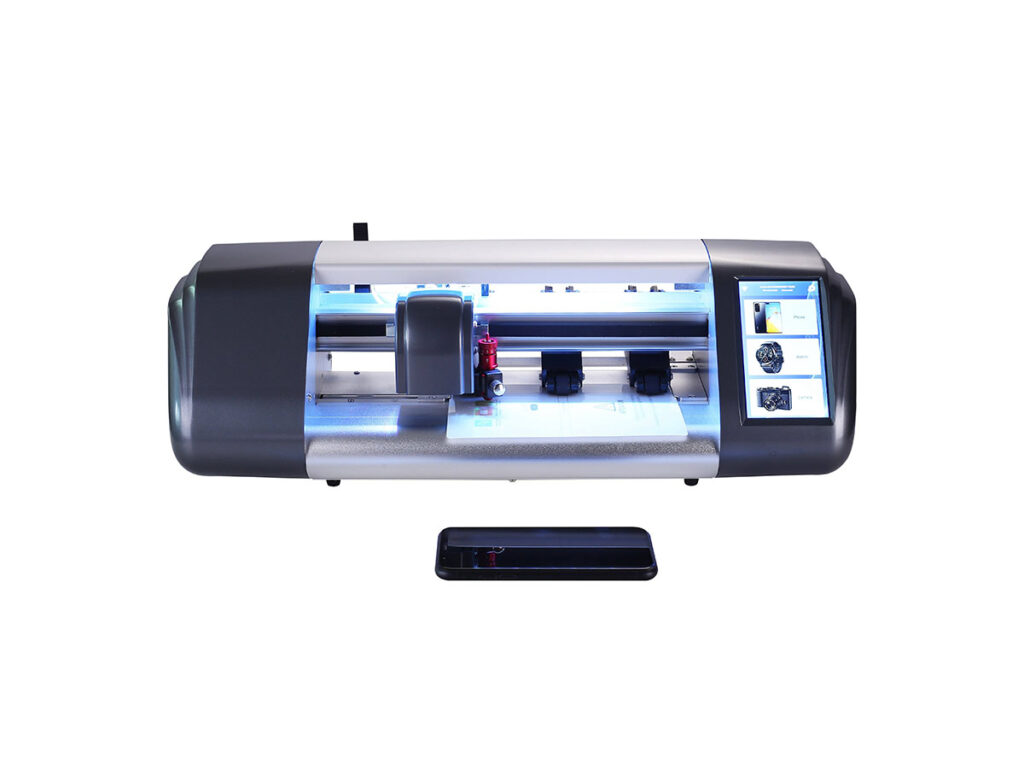

Screen film cutting machines have transformed the way screen protectors are cut and applied, offering automated measurements, customization options, and the use of high-quality materials to ensure ease of application. These machines provide a convenient and efficient solution for protecting the screens of various devices, making them an invaluable tool for tech-savvy individuals and businesses alike.

By investing in these machines, users can achieve precision cuts and perfect results, ultimately prolonging the lifespan of their screens and enhancing the overall user experience.

One of the standout features of these machines is their impressive speed and efficiency. The cutting process is quick and precise, producing clean and accurate cuts without any rough edges or imperfections. Moreover, screen film cutting machines are highly versatile, capable of cutting protectors for a wide range of devices, including smartphones, tablets, smartwatches, and laptops. Adjustable settings allow these machines to accommodate different screen sizes and shapes, offering extensive customization options to meet diverse consumer demands.

Safety is another key aspect of screen film cutting machines. They are designedwith user protection measures, such as safety sensors that detect obstructions between the laser and the material being cut. These sensors ensure that the machine automatically stops if any interference is detected, preventing accidents or damage to the machine itself.

Additionally, advanced features such as automatic material detection ensure proper alignment before cutting, eliminating the possibility of wastage and ensuring accu- rate cuts every time. Many of these machines also come equipped with built-in software that allows users to create and customize their own designs, adding logos, patterns, or personalized messages to the screen guards. This feature is particularly beneficial for businesses looking to enhance their branding and offer unique options to consumers.

In the competitive world of phone accessories retail, models like the Mini HC01 stand out due to their innovation and efficiency. The Mini HC01, for instance, features a high-definition 5.5-inch external display that simplifies navigation and makes the operation efficient and user-friendly, catering to both seasoned professionals and newcomers. This compact and powerful solution not only saves space but also significantly enhances the customer experience, making it an indispensable tool for retailers.

Screen film cutting machines also streamline business operations by simplify- ing SKU management, eliminating excessive inventory and stock challenges, and resolving logistical issues. This results in substantial cost and time savings, as well as the scalability of the system through over-the-air (OTA) updates. The adoption of these machines in daily business routines exemplifies the potential for introducing new methods, streamlining processes, and removing inefficiencies to make a real impact.

Key Features of Modern Screen Film Cutting Machines

Modern screen film cutting machines boast a range of advanced features that have revolutionized the production of screen protectors. These machines enhance precision, efficiency, and overall user experience, making them indispensable in today’s market.

Customization Options

Modern screen film cutting machines offer extensive customization options, catering to a wide range of devices including smartphones, tablets, laptops, and even custom-shaped screens. Users can create unique designs by adding logos, patterns, or personalized messages, thus enhancing their branding and providing a variety of options to consumers.

Precision and Speed

One of the most significant advantages of modern screen film cutting machines is their precision and speed. Traditional methods required extensive manual labor and time, but these machines streamline the entire process, significantly increasing productivity. The cutting blade, controlled by a high-precision motor, ensures accurate and consistent cuts every time, whether through tempered glass or plastic films.This rapid production capability meets the high market demands and keeps consumers satisfied.

Automated Measurements

Automated measurements are another standout feature. These machines come equipped with intelligent sensors that accurately measure the length, width, and curves of various devices, ensuring a perfect fit for each screen protector. This automation eliminates manual measuring, reducing errors and saving time.

High-Quality Materials

These machines utilize premium materials such as tempered glass and high-grade polymer films, which ensure optimal protection for the screen. The materials are scratch-resistant and provide excellent clarity, maintaining the original visual quality of the screen. This use of high-quality materials enhances the durability and effectiveness of the screen protectors.

Safety Features

In terms of safety, screen guard cutting machines are designed with user protection measures in mind. They often have safety sensors that detect any obstructions between the laser and the material being cut. This ensures that the machine auto- matically stops if any interference is detected, preventing accidents or damage to the machine itsel.

Waste Reduction and Environmental Impact

The precision cutting technology of these machines also aids in waste reduction. By minimizing material waste and optimizing resource use, they contribute to a sustainable production process that aligns with modern environmental standards. This eco-friendly approach not only benefits the environment but also translates into cost savings for manufacturers by reducing the need for reworks or replacements.

Advanced Software and Design

The software and design of modern screen film cutting machines further enhance their performance. Advanced software equipped with precise algorithms ensures accurate measurements and consistent cuts. User-friendly design allows operators to input custom measurements and easily adjust settings for different devices, thus ensuring high precision and efficiency.

By incorporating these features, modern screen film cutting machines provide a comprehensive solution that meets the needs of today’s fast-paced and ever-evolving market

Impact on Customer Satisfaction and Store Reputation

Utilizing a screen protector cutting machine in a retail environment can significantly impact customer satisfaction and enhance the store’s reputation. One of the primary ways this is achieved is through the precision and variety the machine offers. The device is capable of cutting raw materials of different thicknesses with an accuracy of up to 0.2mm. This precision ensures that the screen protectors fit perfectly, thereby reducing the chances of customer complaints related to improper fitting.

Additionally, the ability of the machine to store and update a massive cloud database with more than 12,000 models ensures that retailers can cater to a wide range of de- vices, keeping up with new launches. This variety allows customers the freedom to choose from different types of protection materials, including Ultra Clear Finish, Smooth Matt finish, Anti Blue Light Films, and Privacy Films. The availability of these options means customers can find exactly what they are looking for, increasing their satisfaction and loyalty to the store.

The speed and efficiency of the cutting machine also play a crucial role in en- hancing customer satisfaction. Traditional methods that rely on manual labor can be time-consuming, but the automated process of the cutting machine allows for

quick production of screen protectors, meeting high market demands and ensuring a consistent supply. This timeliness can prevent delays and keep consumers happy with prompt service.

Moreover, confident customers are less likely to opt out of marketing emails and other forms of customer relationship management if they feel their personal data is secure. Implementing modern physical and digital security measures can protect this valuable asset, thereby bolstering customer trust and loyalty. This trust is fur- ther reinforced by the retailer’s ability to offer customized and high-quality products, making the shopping experience more personalized and satisfying.

Cost Structure and Profitability

The cost structure and profitability of implementing a screen protector cutting mach- ine in your store can significantly influence your business operations, especially in a volatile market economy. The initial investment in a screen protector cutting machine is a pivotal consideration. As outlined in recent industry reports, the cost per unit and production value varies, with gross margins playing a crucial role in determining the return on investment (ROI).

A key advantage of these machines is their ability to cater to the growing demand for personalized customization among customers. This demand is particularly high among technology shopkeepers and low-cost entrepreneurs who face the challenge of meeting diverse customer needs while managing inventory efficiently. For instance, the FORWARD team has developed segmentation solutions to address pain points such as difficult inventory turnover and excess stock, which traditionally lead to reduced profits for mobile phone shops.

Adopting screen film cutting machines also contributes to optimized stock levels by allowing stores to produce protectors on demand. This reduces the need for maintaining large inventories, thereby minimizing associated costs like storage and obsolescence. Efficient resource allocation is another benefit, as automated systems free up staff from manual tasks, allowing them to focus on strategic activities that drive profitability.

Additionally, these machines often come with integrated software solutions that provide valuable insights into sales trends and inventory needs. This real-time data enables businesses to avoid overstocking and stock-outs, which are common issues that can tie up capital and result in lost sales opportunities. By improving inventory management and reducing costs in various areas such as labor and purchasing, businesses can enhance customer satisfaction and loyalty, ultimately boosting profitability.

Case Studies

Improving Data Collection and Validation

In one notable case, a retail store implemented a structured process for collecting and validating market data using a screen protector cutting machine. This approach involved the identification of primary and secondary data sources, such as in-depth interviews with industry experts and comprehensive reviews of market journals and government websites. The store’s analysts carried out a detailed evaluation of market dynamics, including key drivers and trends, which enabled them to better predict market demands and optimize their inventory accordingly. The collected data was validated and corroborated through triangulation with proprietary databases and consultations with industry experts.

Customization Solutions for Mobile Shops

A mobile phone shop struggled with meeting the increasing demand for personalized phone cases and managing excessive inventory. By integrating a screen protector cutting machine, the shop was able to address these pain points effectively. The machine allowed for rapid customization of phone cases, reducing inventory costs and increasing sales turnover. This solution proved to be a significant advantage in a market where customer needs are increasingly diverse and personalized.

Leveraging Market Insights

A store specializing in screen protectors utilized data from various sources, including paid databases and internal repositories, to gain comprehensive market insights.

By synthesizing and validating this data, the store could identify market needs and trends, which informed their business strategies and product offerings. This methodical approach to data analysis helped the store stay ahead of market changes and better serve their customers with relevant products and services.

Boosting Consumer Trust

Lastly, a retailer used a screen protector cutting machine as part of their strategy to enhance consumer trust and loyalty. By implementing robust privacy and security measures, the retailer was able to reassure customers that their personal data was safe, thereby increasing customer confidence and engagement. This led to improved customer retention and allowed the retailer to use collected data for targeted mar- keting and product development, further driving business growth.

These case studies highlight the versatile applications and benefits of using a screen protector cutting machine in retail environments, from improving data collection and validation processes to enhancing cybersecurity and boosting consumer trust.

Future Trends in Screen Protector Cutting Technology

The landscape of screen protector cutting technology is continuously evolving, driven by advancements in materials science, precision engineering, and automation. These developments aim to further enhance the efficiency, customization, and environmen- tal sustainability of screen protector production.

Integration with Advanced Technologies

Emerging technologies such as Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) are set to revolutionize the screen protector cutting in- dustry. AI and ML can optimize the cutting process by analyzing vast amounts of data to predict wear and tear on blades, schedule maintenance, and reduce downtime, thereby increasing overall productivity. IoT-enabled devices can provide real-time monitoring and diagnostics, ensuring that machines operate at peak efficiency and reducing the risk of mechanical failures.

Enhanced Customization and Precision

Future screen film cutting machines are expected to offer even greater levels of customization and precision. Advanced sensor technology and high-resolution imaging can enable machines to perform ultra-precise cuts, accommodating the latest device designs, including curved screens and edge-to-edge displays. More- over, automated software updates can ensure that machines stay current with new device models as soon as they are released, providing a seamless integration into the production workflow.

Environmental Sustainability

Sustainability is a growing concern in manufacturing, and future trends in screen protector cutting technology are likely to address this issue head-on. Next-generation machines will focus on minimizing material waste through improved cutting accuracy and optimizing resource use. Additionally, manufacturers are expected to explore eco-friendly materials for screen protectors, reducing the environmental impact of both the production process and the end product.

Increased Automation and Efficiency

Automation will continue to be a pivotal trend, with next-generation machines in- corporating more sophisticated robotics and automated handling systems. These advancements will further reduce the need for manual intervention, lower labor costs, and improve production speeds. Automated sorting and packaging solutions will streamline the entire manufacturing process, from cutting to distribution, making it possible to meet the growing demand for high-quality screen protectors rapidly.

Comments

Achieving a Perfect Fit: Tips for Using Your Screen Protector Cutter

“Achieving a Perfect Fit: Tips for Using Your Screen Protector Cutter” is a comprehensive guide designed to help users understand the nuances and best practices involved in using screen protector cutting machines.

Screen Protector Cutting Machine Price vs. Performance-Finding the Right Balance

The topic of “Screen Protector Cutting Machine Price vs. Performance” explores the critical balance between the cost and functionality of machines used for cutting screen protectors.

Screen Guard Machine- The Essential Tool for Tech Lovers

Screen guard machines are specialized devices designed to produce protective films and shields for electronic screens, such as those on smartphones, tablets, and laptops.

Screen Guard Cutting Machine

Screen guard cutting machine offers precise, fast, and customizable cutting for hydrogel screen protectors, ideal for mobile accessory businesses shop.

Are Hydrogel Screen Protectors Any Good?

Both hydrogel and tempered glass screen protectors have their merits. Your choice should depend on your specific needs and preferences.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.