Understanding the Cost of Screen Protector Cutting Machines: What to Expect

Table of Contents

Extract

Summary

These machines provide the capability to produce custom-fit screen protectors for various devices, including smartphones, tablets, and smartwatches. However, the cost of these machines can vary significantly depending on a variety of factors. This article explores what influences the price of screen protector cutting machines and what you should expect when considering this investment.

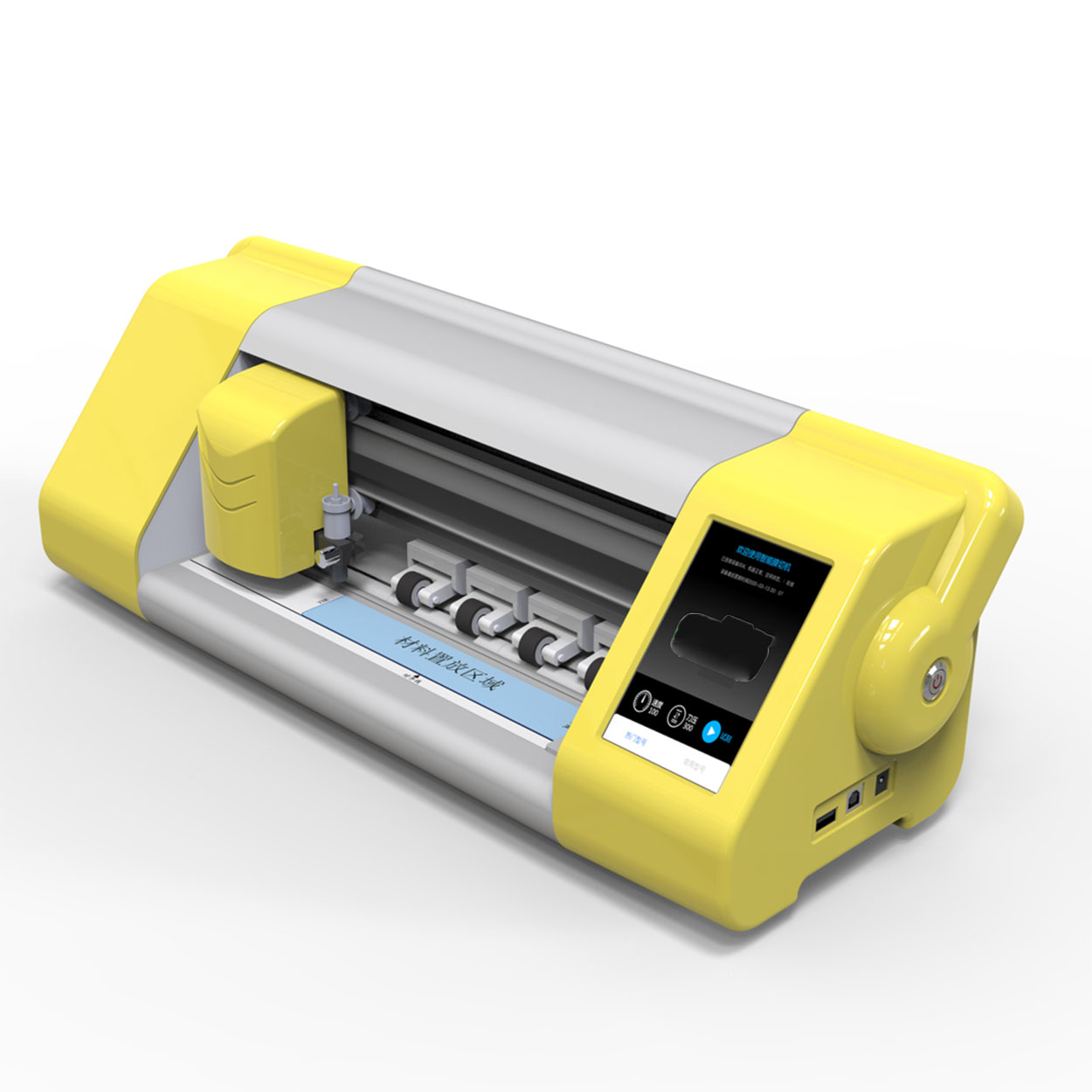

Overview of Screen Protector Cutting Machines

Screen protector cutting machines are designed to cut protective films to the exact dimensions required for a wide range of devices. They are equipped with advanced technology that allows for precise cuts, ensuring a perfect fit for each device. These machines are crucial for businesses that want to offer customized screen protectors and stay competitive in the market.

Importance of Investing in a Screen Protector Cutting Machine

Investing in a screen protector cutting machine allows businesses to:

- Offer customized products tailored to individual device specifications.

- Reduce waste by cutting materials only as needed.

- Increase customer satisfaction with perfectly fitting protectors.

- Enhance operational efficiency by streamlining the production process.

Given these benefits, understanding the cost dynamics of these machines is vital for making an informed purchasing decision.

Factors Influencing the Cost of Screen Protector Cutting Machines

Several factors affect the price of screen protector cutting machines, including the type of technology used, the precision and accuracy of the machine, software capabilities, build quality, and brand reputation. Let’s delve into each of these factors in detail.

Type of Cutting Technology

The cutting technology employed by the machine is one of the most significant determinants of its cost. There are generally two types of cutting technologies used in screen protector cutting machines: die cutting and digital cutting.

Die Cutting Technology

Die cutting is a traditional method where a pre-shaped die is used to cut the screen protector material. This method is less flexible and typically less expensive, but it’s ideal for businesses that produce large quantities of the same shape. Die cutting machines are cost-effective for high-volume production, but they lack the versatility needed for custom orders.

Digital Cutting Technology

Digital cutting machines use advanced technology, such as laser or blade cutting, guided by computer software. These machines can cut screen protectors to the exact specifications required for various devices without needing a physical die. Digital cutting technology is more versatile and precise, making it suitable for businesses that need to produce a wide range of custom-fit protectors. However, this advanced technology typically comes at a higher cost.

Precision and Accuracy

Precision is crucial in screen protector cutting, as it ensures the final product fits perfectly on the device. The precision and accuracy of the machine directly influence its price.

High-Precision Cutting Mechanisms

Machines that offer high precision, often at the micron level, are equipped with advanced sensors and cutting mechanisms that ensure each screen protector is cut to exact specifications. These machines are more expensive due to their sophisticated technology, but they provide superior results, which is essential for maintaining customer satisfaction and minimizing product returns.

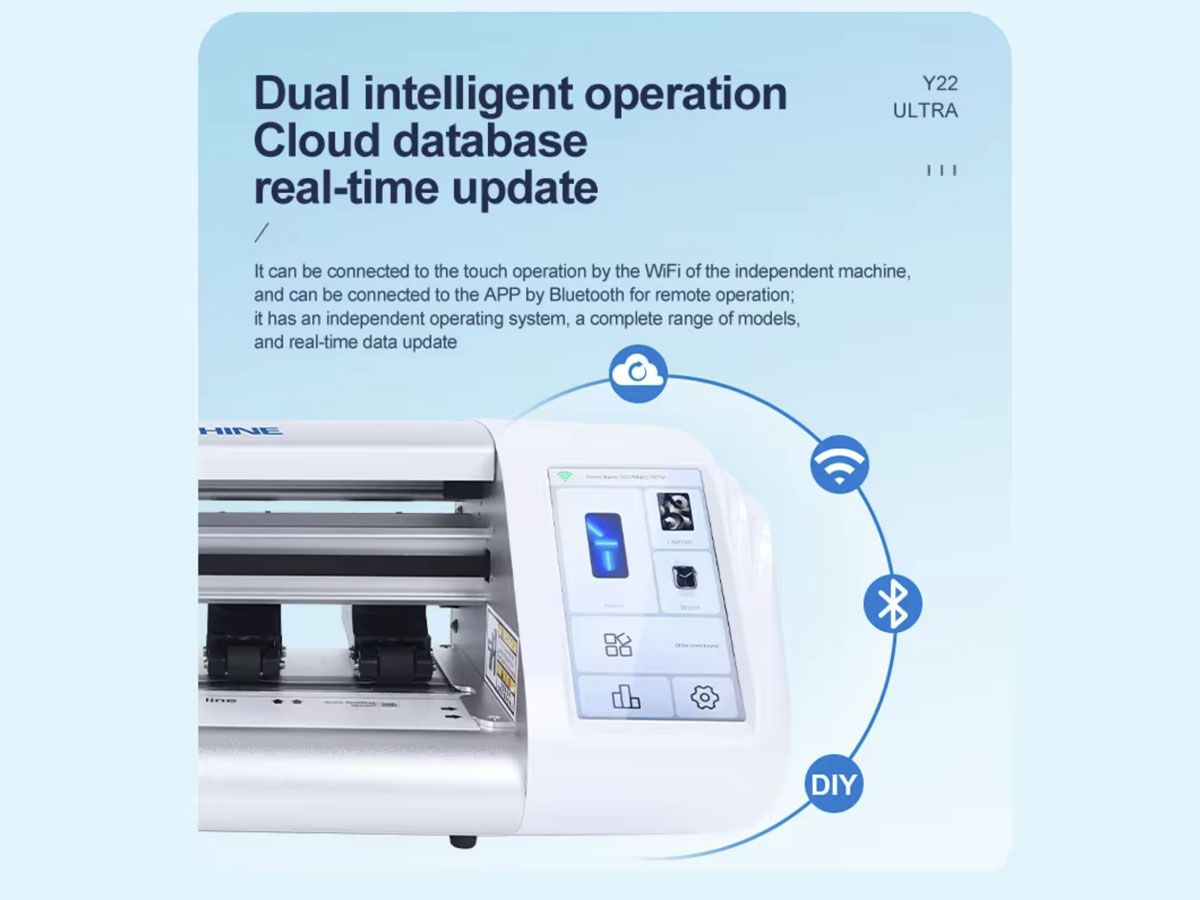

Software and Template Database

The software that drives the screen protector cutting machine is another key factor that influences its cost. The sophistication of the software, along with the range and variety of templates it offers, can significantly impact the machine’s price.

Template Variety and Software Updates

Machines with a comprehensive database of templates for various devices allow businesses to quickly and easily produce screen protectors for a wide range of models. Additionally, machines that receive regular software updates to include templates for new devices as they enter the market are typically more expensive. However, the investment in such a machine ensures that your business can continue to offer up-to-date products without requiring manual adjustments or custom programming.

Customization and Flexibility

Some machines offer advanced customization options, enabling businesses to create bespoke screen protectors tailored to unique devices or specific customer needs. This level of flexibility and customization increases the machine’s cost, but it also expands your business’s capability to cater to niche markets and personalized orders.

Build Quality and Materials

The materials used in constructing the machine and its overall build quality play a significant role in determining its price. Higher-quality materials and a robust build lead to a more durable machine that can withstand continuous use.

Durability and Maintenance Costs

Machines made from high-quality materials, such as stainless steel and reinforced plastics, tend to be more expensive. However, they offer greater durability and require less maintenance over time. Investing in a well-built machine can save money in the long run by reducing downtime and repair costs.

Speed and Efficiency

The speed at which a screen protector cutting machine can produce finished products also affects its cost. High-speed machines capable of cutting protectors quickly without sacrificing accuracy are generally more expensive.

High-Volume Production Capabilities

For businesses that need to produce large quantities of screen protectors efficiently, a high-speed machine is essential. These machines are designed to handle high production volumes, which can significantly improve operational efficiency and profitability. The higher cost of these machines is often justified by the increased output and reduced labor costs.

Machine Size and Portability

The physical size of the machine and its portability are additional factors that influence its cost. Larger, industrial-grade machines are typically more expensive, but they offer greater versatility and can handle a broader range of materials and device sizes.

Compact Machines for Small Businesses

Smaller, more portable machines are less expensive and are ideal for businesses with limited space or those offering mobile services. However, they may have limitations in terms of the size and types of devices they can accommodate. For small businesses, a compact machine can be a cost-effective solution that meets their needs without the added expense of larger equipment.

Brand Reputation and Manufacturer Support

The brand of the machine and the level of support offered by the manufacturer can significantly impact its cost. Established brands with a reputation for quality and reliability often charge a premium for their machines.

Brand Premium and Reliability

Machines from well-known brands are often more expensive due to their proven track record of reliability, quality, and performance. Investing in a reputable brand can provide peace of mind, as these machines are typically backed by extensive warranties and customer support services.

After-Sales Support and Warranty

A machine that comes with comprehensive after-sales support and a robust warranty may have a higher upfront cost, but it offers significant value in terms of ongoing maintenance and troubleshooting assistance. This support can minimize downtime and ensure your machine continues to operate efficiently, which is crucial for maintaining business operations.

Additional Features and Accessories

The inclusion of additional features and accessories can also affect the price of a screen protector cutting machine. These features enhance the machine’s functionality but come with additional costs.

Automation Features

Automation features, such as auto-loading and unloading of materials, as well as touchscreen controls, can significantly reduce the need for manual labor and streamline the production process. These features add to the machine’s overall cost but can improve efficiency and reduce labor costs in the long run.

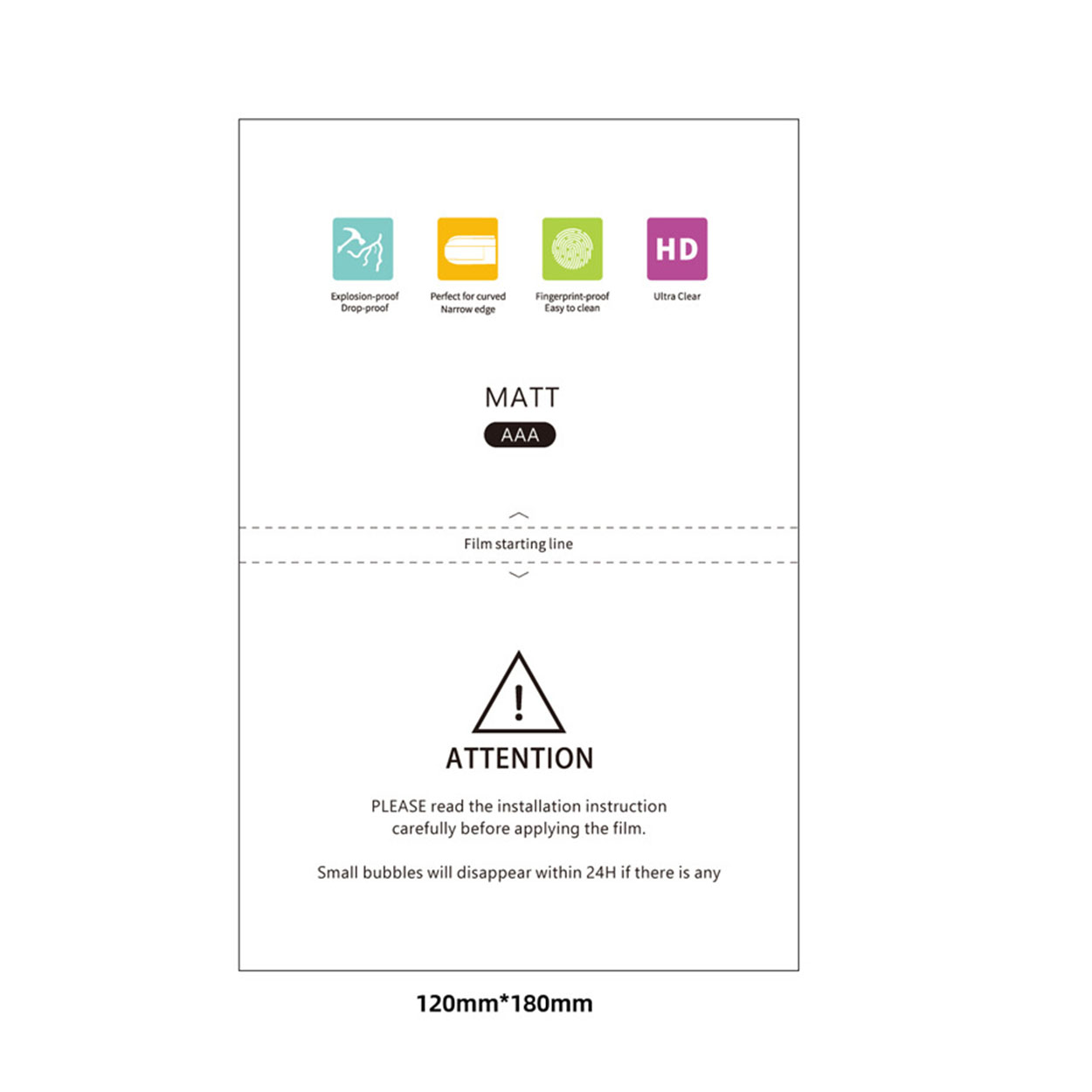

Material Compatibility

Some machines are designed to work with a variety of materials, including different types of screen protector films. Machines with greater material compatibility are generally more expensive, as they require more advanced cutting mechanisms and software to handle different materials effectively.

Energy Efficiency and Operating Costs

Energy efficiency is an increasingly important consideration for businesses, particularly those looking to reduce operating costs. Energy-efficient machines typically have a higher upfront cost but can lead to significant savings over time.

Long-Term Savings with Energy Efficiency

Investing in an energy-efficient machine can lower your electricity bills over time, making it a cost-effective choice in the long term. Additionally, energy-efficient machines are often seen as more environmentally friendly, which can enhance your business’s reputation and appeal to eco-conscious customers.

Market Factors and Availability

External market factors, such as supply and demand, as well as the availability of certain machines, can also influence their cost.

Supply Chain Disruptions

Global supply chain disruptions, economic downturns, or geopolitical events can affect the availability and price of screen protector cutting machines. During times of high demand or limited supply, prices may increase. Conversely, during periods of lower demand, manufacturers may offer discounts or promotions, providing an opportunity to purchase at a lower price.

What to Expect When Budgeting for a Screen Protector Cutting Machine

When budgeting for a screen protector cutting machine, it’s important to consider not only the initial purchase price but also the total cost of ownership. This includes maintenance and repair costs, operating expenses, and potential savings from energy efficiency.

Initial Investment and Return on Investment (ROI)

The initial cost of a screen protector cutting machine can range from a few thousand to several tens of thousands of dollars, depending on the factors discussed above. However, the return on investment (ROI) can be significant, particularly for businesses that plan to produce large quantities of screen protectors or offer highly customized products. The key is to choose a machine that aligns with your business’s specific needs and growth plans.

Maintenance and Repair Costs

When evaluating the cost of a screen protector cutting machine, it’s crucial to factor in potential maintenance and repair costs. Machines that require frequent maintenance or have expensive replacement parts can increase your overall costs. Opting for a machine with a strong warranty and robust after-sales support can mitigate some of these expenses.

Operating Costs and Efficiency

Operating costs, including energy consumption, labor, and material costs, should also be considered when budgeting for a screen protector cutting machine. Machines that are more energy-efficient and require less manual labor can offer significant savings over time, even if they come with a higher initial price tag.

Longevity and Durability

Investing in a higher-quality machine that is built to last can save money in the long run. Durable machines that can withstand continuous use and require less frequent repairs or replacements offer better value for money, even if they are more expensive upfront.

Discounts and Promotions

Finally, keep an eye out for discounts, promotions or financing options offered by the manufacturer or distributor. These can have a significant impact on the total cost of the machine and provide an opportunity to purchase a high-quality machine at a low price..

Comments

How to Get Out Air Bubbles in a Screen Protector?

By following these guidelines, you can ensure a smooth, bubble-free screen protector application, keeping your device safe and looking great.

HD Hydrogel Screen Protector For Film Cutting Machine

The HD Hydrogel Screen Protector is an innovative solution that offers protection without compromising the ultra clarity of your HD screen. This article will explore the features, benefits, and installation process of this revolutionary product, ensuring you make an informed choice for your beloved device.

Universal Matte Screen Protector For Screen Cutter

Using our Matte screen protectors enhance grip during intense gaming, preventing slippery aim or movement issues caused by sweat, ensuring superior control.

Cost-Benefit Analysis of Investing in a Hydrogel Blade Cutting Machine

A Cost-Benefit Analysis of Investing in a Hydrogel Blade Cutting Machine delves into the financial, operational, and strategic implications of acquiring and utilizing specialized equipment for cutting hydrogel films.

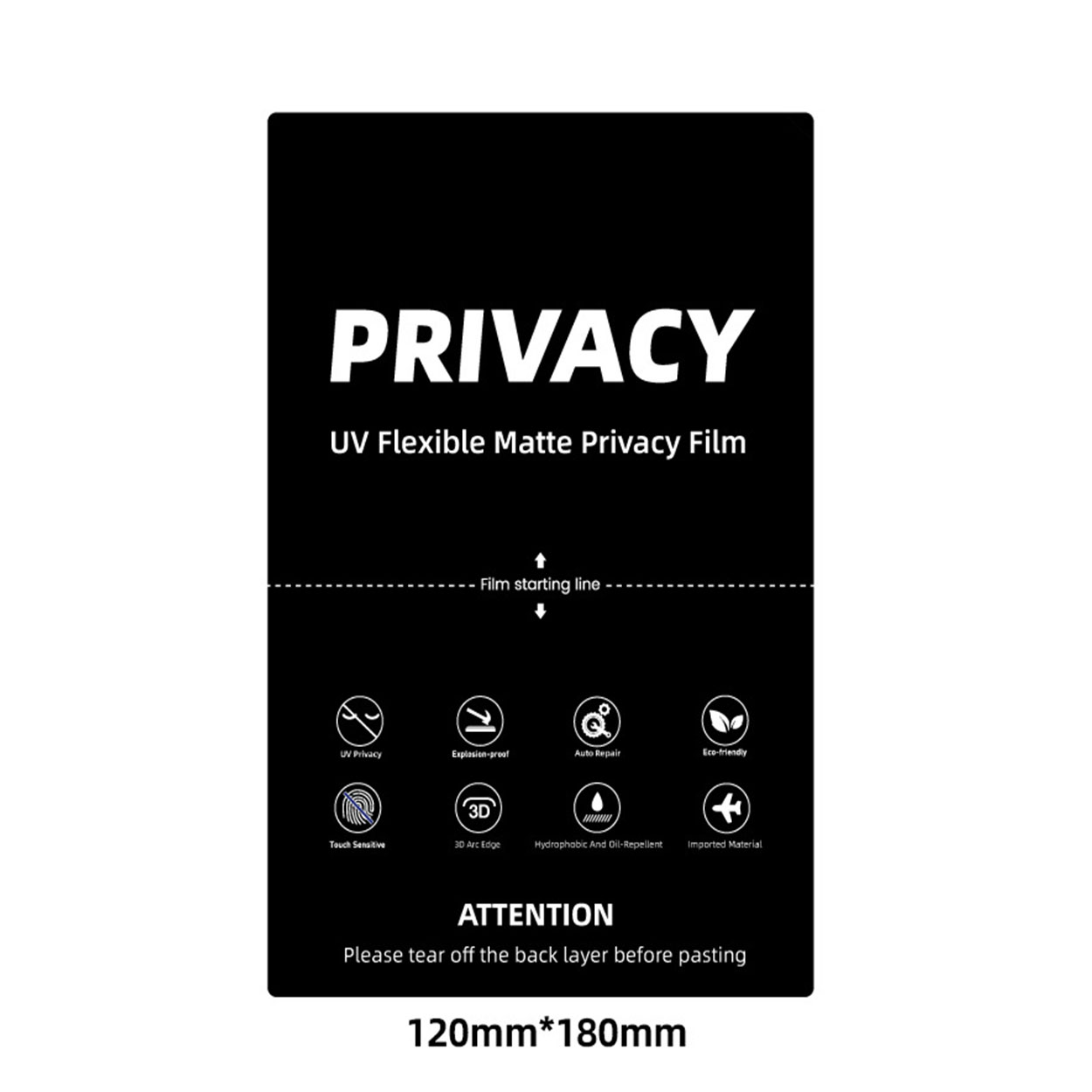

Intelligent UV Matte Privacy Screen Protector For Cutter

Discover the future of mobile protection with our guide to screen protector cutting machines. Learn how film cutters create custom screen protectors

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.