How Mobile Phone Screen Protector Cutting Machine Work?

Table of Contents

Summary

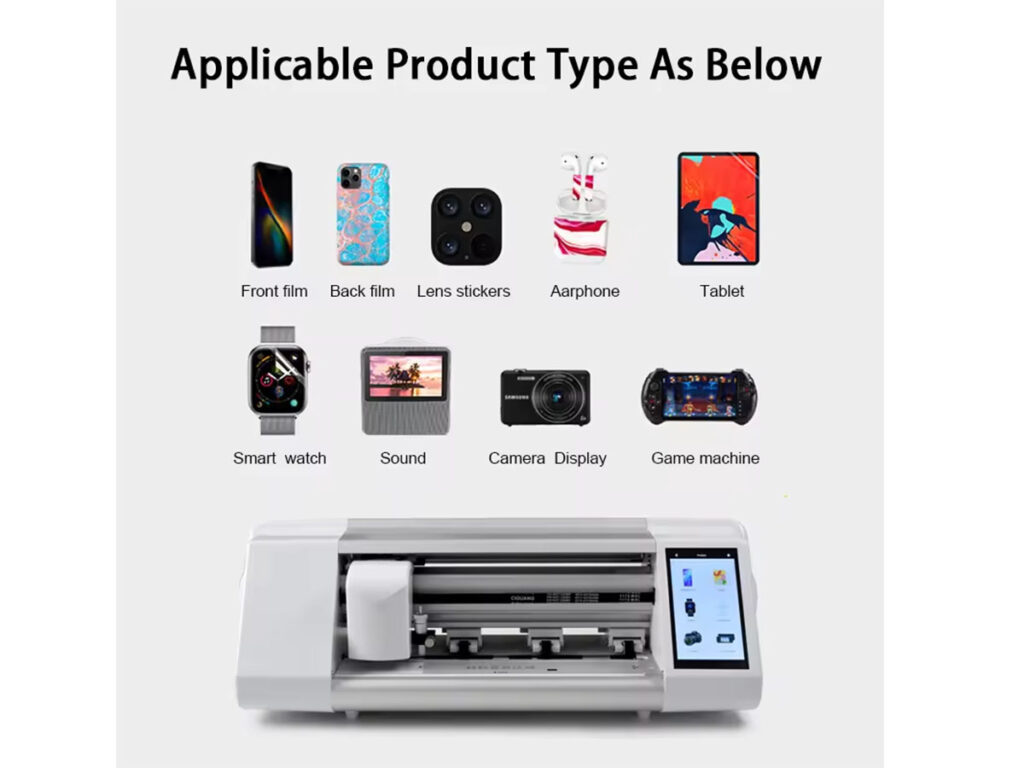

These machines have revolutionized the screen protector industry by allowing on-demand production, significantly reducing the need for pre-made inventory and enabling retailers to meet the diverse needs of their customers promptly. Screen protector cutting machines are essential for ensuring that protective films perfectly fit the screens of mobile phones, tablets, and other electronic devices, thereby enhancing device longevity and user experience. The significance of these machines lies not only in their ability to cut screen protectors

to exact dimensions but also in their advanced technological features. Modern cutting machines are equipped with high-precision blades, intuitive touch screen displays, and comprehensive databases containing thousands of templates for various device models. These machines also integrate seamlessly with printers, allowing users to print and cut customized designs for back films, further expanding their functionality. The use of recyclable materials and sustainable manufacturing practices underscores the industry’s commitment to environmental responsibility. Notably, the operation of a screen protector cutting machine involves sophisticated positioning technology and adjustable pressure wheels, which ensure precise and consistent cuts across different materials, including PET, TPU, and tempered glass. Unlike laser cutting, which can be noisy and environmentally unfriendly, these machines use physical blades that provide a safe, noise-free, and pollution-free cutting process, making them suitable for various environments such as retail stores and homes. Moreover, advanced features like real-time data updates, cloud-based template databases, and user-friendly interfaces enhance operational efficiency and user convenience. However, the adoption of screen protector cutting machines is not without challenges. Initial acquisition and maintenance costs can be high, and operating these machines requires a certain level of technical expertise. Additionally, while these machines reduce the need for pre-made inventory, they still depend on the availability of raw materials. Despite these limitations, the future of screen protector cutting machines looks promising, with ongoing advancements in AI, machine learning, IoT connectivity, and sustainable practices expected to drive further improvements in precision, efficiency, and customization capabilities.

History and Development

The evolution of mobile phone screen protectors has been a remarkable journey, driven by advancements in both material science and manufacturing technologies. In the early days of PDAs and smartphones, screen protectors were primarily made of plastic. These initial plastic protectors were designed to prevent scratches on the relatively fragile screens of early devices. However, they often reduced screen clarity and were challenging to apply without trapping dust or air bubbles. As touchscreen devices became ubiquitous, the demand for better screen protectors grew. This led to improvements in materials and design, resulting in modern plastic screen protectors that are more durable, clearer, and easier to install. The significant leap in screen protector technology came with the introduction of tempered glass screen protectors. Unlike their plastic predecessors, tempered glass protectors offered superior protection against not only scratches but also high-impact drops. Manufacturing processes also evolved to meet the growing and changing demands. he production of screen protectors began to incorporate sophisticated machinery, such as rotary die cutting machines, which provided precise, consistent cuts and

could handle various shapes and sizes of device screens. These machines ensured that every protector was cut identically, reducing waste and improving efficiency through automation. Furthermore, the screen protector manufacturing process has embraced sustainability, with manufacturers actively using recyclable materials and sustainable practices to minimize ecological impact. This forward-thinking approach not only enhances the functionality and quality of the screen protectors but also aligns with broader environmental responsibility goals.

Components of a Mobile Phone Screen Protector Cutting Machine

A mobile phone screen protector cutting machine comprises several critical components designed to ensure efficient and precise operation. These components collectively enable the machine to cut various types of screen protectors with high accuracy and speed, catering to the diverse needs of mobile phone users and retailers.

Cutting Blade

The cutting blade is one of the most essential parts of the screen protector cutting machine. Typically, the machine comes equipped with three pieces of cutting blades . These blades are responsible for slicing the screen protectors to the exact dimensions required for different mobile phone models. Advanced machines use high-precision physical cutting knives that offer cutting accuracy up to 0.1 mm, ensuring precise cuts and proper fitment on the phone screen.

Touch Screen Display

Modern screen protector cutting machines feature an intuitive touch screen display for easy operation. The display, usually around 5 inches (12.7 cm), allows users to select the desired template and cutting options. Multiple languages are supported, including Chinese, English, French, Portuguese, Russian, and German, making the machine user-friendly and accessible globally.

Power Adapter and Non-Slip Mat

To ensure the machine operates smoothly, it is equipped with a power adapter and a non-slip mat. The power adapter supplies the necessary electrical power, while the non-slip mat stabilizes the machine during operation, preventing any movement that could affect cutting accuracy.

Database and Templates

The cutting machine is integrated with an extensive database containing more than 30,000 templates, which are updated daily to include new models. This database allows users to choose from various templates suitable for different mobile phones and types of screen protectors, such as HD clear films, matte screen protectors, anti-blue-ray films, and privacy films.

Connectivity and Printers

One of the standout features is the machine’s ability to connect with printers. Users can select photos from their mobile phone album and print them using a connected printer. The built-in [Print at Will] menu facilitates stable connectivity with a Phone Skin Printer, enabling on-demand printing and cutting of back film patterns.

Pressure Wheels

To accommodate different film hardness and thickness, the machine includes four adjustable pressure wheels. These wheels allow for the customization of cutting pressure, ensuring precise cuts across various types of screen protectors.

After-Sales and Support

A professional after-sales team provides extensive support, including free teaching videos and lifelong technology updates. Additionally, global backup and high concurrency support through dozens of high-performance cloud servers ensure reliable operation and quick service response.

Consumables Identification Code

For the machine to function correctly, users must enter the right consumables identification code printed on the packaging box. This system helps in managing the use of cutting films and maintaining inventory control.

High-Quality Standards

The machine and its components are subjected to rigorous quality control, certified by major brands such as Huawei and Samsung, ensuring excellent performance and durability. By integrating these components, a mobile phone screen protector cutting machine provides a comprehensive, efficient, and precise solution for producing screen protectors, meeting the demands of various users and markets.

Working Principle

The mobile phone screen protector cutting machine operates on a precise positioning technology that ensures the cutter starts at the exact position required for accurate cuts and hole placements. The cutting knife employed in the machine boasts a high precision, with an accuracy of up to 0.1 mm. This precision allows the machine to cut various soft material screen protective films efficiently, without the need for buying additional cutting credits. The machine is designed with 4 adjustable pressure wheels, which accommodate films of different hardness and thickness. Unlike laser cutting, which can be noisy and cause pollution, this machine uses a blade for cutting, making it safe, noise-free, and pollution-free. This characteristic makes it suitable for use in environments such as shopping malls and homes. Furthermore, the machine features a 6-inch HD screen, which simplifies operation, and it is equipped with a self-developed cloud system for timely data updates. A unique feature of this machine is the back film pattern customization function, which allows users to print their own back film designs. Additionally, the software upgrade is free, and new model data updates are provided at no additional cost. The process begins by drilling a small hole, followed by precise movements in the x and y directions to continue the cutting process without shifting the initial position. This meticulous approach ensures that the cutting is both accurate and efficient, maintaining the integrity of the screen protector film.

Types of Cutting Machines

Mobile phone screen protector cutting machines come in various types, each designed to cater to different materials and specific cutting needs. These machines are pivotal in producing high-quality screen protectors that perfectly fit various digital devices.

Rotary Die Cutting Machines

Rotary die cutting machines are widely used for producing display and touch screen protectors due to their precision and efficiency.

Precise Cutting: These machines deliver precise and consistent cuts, ensuring screen protectors perfectly fit the dimensions of various device screens.

High-Speed Production: Rotary die cutting machines operate at high speeds, facilitating the production of a higher volume of screen protectors in less time, thereby increasing production efficiency.

Versatility: They can cut various materials such as PET, TPU, and tempered glass, which are commonly used in screen protector production.

Laminating and Embossing: Some rotary die cutting machines can perform additional operations like laminating and embossing, adding value to the screen protectors.

Hydrogel Screen Protector Cutting Machines

Hydrogel screen protector cutting machines are designed for cutting flexible films but are not suitable for cutting glass screen protectors.Automatic Film Feeding: Features such as automatic induction feeding save time and increase convenience.

Fast Cutting: These machines can cut one screen protector in just 30 seconds, making them highly efficient.

Smooth and Flat Cutting Lines: Equipped with imported tungsten steel cutter heads, these machines ensure smooth and burr-free cutting lines.

Zero stock Pressure: They solve inventory issues by allowing on-demand cutting, eliminating the need for large stockpiles

Laser Cutting Machines

Laser cutting machines are specifically used for cutting glass screen protectors. These machines require a larger site area and entail environmental considerations.

Environmental lmpact: Laser cutting machines involve environmental pollution and require measures to mitigate their impact.

Edge Polishing: After cutting, the glass edges need to be polished to prevent sharp, right-angled edges that could cause injury.

Intelligent Film Cutting Machines

Intelligent film cutting machines offer versatile control modes and a range of cutting materials.

Multiple Control Modes: They can be operated using a 5-inch quick-response screen or controlled via a cellphone app.

Variety of Cutting Materials: These machines support various materials like HD clear, matte.privacy, and anti Blu-ray films.

Warranty and Support: Manufacturers provide a one-year warranty and free replacement parts for non-human-caused failures during the warranty period

Software Integration

These machines often integrate advanced software features that optimize the cutting process:

Design Visualization: Users can see how designs will cut and alter the order of cutting paths. enhancing precision and efficiency.

Material Utilization: High-performance nesting software ensures efficient material usage by fitting large numbers of parts on sheets and filling unused spaces.

Applications

Mobile phone screen protector cutting machines offer a range of applications designed to enhance both consumer and retailer experiences. These devices are pivotal in providing precise and customized screen protectors for various electronic devices, ensuring optimal protection and usability.

Easy Application

Modern screen protector cutting machines, such as the ProtectionPro system, facilitate an easy and efficient application process. Users can choose between the Pro (wet) solution, which uses a proprietary ProInstall Gel, or a standard (dry) installation ideal for high-volume scenarios or newer associates. These systems enable sales associates to quickly find the appropriate device pattern via an app, create precise cuts, and perform installations swiftly and accurately. Detailed instructions and live support ensure a smooth, bubble-free application every time.

Customization and Precision

Screen protectors, typically made from thin sheets of clear plastic, can be custom-cut to fit any device’s screen. This customization process requires measuring the screen, cutting along pre-marked lines, and ensuring an exact fit. Advanced machines may use templates or photocopies to achieve precise dimensions. The flexibility of these machines allows users to select the proper size and shape for any electronic device, significantly reducing waste and ensuring a perfect fit every time.

Liquid Screen Protectors

While traditional plastic and tempered glass screen protectors dominate the market, liquid screen protectors have also emerged as an option. These protectors involve applying a solution onto the screen and buffing it off. However, their effectiveness and durability are debatable. The protective layer is often too thin to prevent tough scratches, and the product typically wears off over time without clear indicators of its remaining effectiveness. Due to these limitations, liquid screen protectors are generally not recommended.

Mobile App Integration

Integrating mobile applications into the screen protector cutting process has revolutionized the workflow for designers and sales associates. Applications like the Red Dot Design App and Behance offer platforms for ideation and showcasing creative designs. For more hands-on design and drafting, tools such as AutoCAD 360 and Fusion 360 allow for drafting, editing, and annotating directly from a smartphone. These applications enhance productivity by connecting to cloud storage and facilitating real-time collaboration, making them invaluable for the screen protector design and customization process.

Advantages

Mobile phone screen protector cutting machines offer numerous advantages that make them indispensable in the modern manufacturing landscape. One of the most significant benefits is the ability to import and export industry-standard file formats, allowing seamless interoperability with any other CAD application. This feature ensures that manufacturers retain access and ownership of their files, facilitating easy transfer to other CAD applications and enhancing digital security within an open platform. The machines are designed to be user-friendly, removing complexity and streamlining CAD functions. This enables a wider range of employees to become competent

in production tasks using CAD, reducing reliance on a few highly skilled operators. Consequently, this leads to increased workflow efficiency and mitigates risks associated with the absence or departure of key personnel. Another key advantage is the significant increase in yield. Typically, customers see an increase of between 6 and 8% in material yield, which translates into substantial savings over the annual cost of materials. The enhanced precision and efficiency of these machines ensure that cutting errors are minimized, maximizing the use of raw materials. In terms of durability and accuracy, these machines excel. They are capable of cutting raw materials of varying thicknesses with precision up to 0.2mm. This high level of accuracy is crucial for creating screen protectors that perfectly fit their designated devices. Moreover, advanced cutting technologies such as laser-cutting, waterjet cutting, or die-cutting ensure that each screen protector is meticulously crafted to match the digital blueprints created during the design phase. These machines also offer a variety of functional films, including HD clear film, anti-blue light film, matte film, and flexible nano-glass films, all at favorable prices. The versatility in materials allows manufacturers to cater to diverse customer preferences and needs, further enhancing the product’s marketability. Additionally, the machines are equipped with comprehensive quality control measures to ensure that each screen protector meets stringent standards. Regular checks during the manufacturing process monitor the accuracy of cutting and shaping, and final inspections rigorously test the finished products for any defects or imperfections. This guarantees that consumers receive reliable and high-quality products.

Limitations

While mobile phone screen protector cutting machines offer numerous benefits, they also come with certain limitations that should be considered.

Inventory Management

Although these machines alleviate the need for pre-made inventory by cutting screen protectors on-demand, there is still a dependency on having the raw materials available. If the raw materials are not well-stocked, it could result in delays and inefficiencies, contradicting the zero-inventory advantage.

Initial Cost and Maintenance

The initial cost of acquiring a high-quality screen protector cutting machine and its associated software can be substantial. Some machines range from $199 to $900, depending on their capabilities and additional features like laser edge finding. Furthermore, regular maintenance, such as cleaning blades, adjusting positions, and lubricating parts, is essential to ensure long-term efficiency and accuracy . Improper maintenance can lead to decreased performance and increased wear and tear.

Technical Expertise

Operating a screen protector cutting machine requires a certain level of technical expertise. Users need to be familiar with the programming and software interfaces. Incorrect programming or poor handling can result in inefficiencies and even damage to the machine. Therefore, businesses may need to invest in training their staff to ensure optimal usage.

Freight and Shipping Costs

Even though some companies offer free shipping for orders where the postage does not exceed $195, any excess amount has to be covered by the buyer. This can add an additional cost burden, particularly in scenarios where the shipping costs are significantly high due to the size or weight of the machine.

Compatibility and Updates

Although these machines boast a massive cloud database that is applicable to various models of mobile phones, tablets, and other digital products, the database requires constant updates to remain relevant. Inconsistent updates or delays in adding new models can limit the machine’s applicability and effectiveness.

Fragility of Components

Screen protectors, especially those made from thermoplastic polyurethane (TPU) or tempered glass, can be delicate. While TPU offers some self-healing properties, tempered glass protectors are prone to breaking, and any damage during the cutting process could lead to additional costs. The cutting precision of less than 0.1mm is high, but it also requires highly accurate data and calibration to avoid errors.

Warranty and After-Sales Support

Issues related to incorrect quantities, package damage, or defects are covered under warranty, but this often excludes artificial defects and products out of warranty. Although a professional after-sales team can provide support, the effectiveness of this service varies and may not always meet user expectations. These limitations underscore the importance of careful consideration and comprehensive planning when integrating a screen protector cutting machine into a business operation.

Future Trends

The mobile phone screen protector cutting machine industry is continuously evolving, driven by advancements in technology and changing consumer preferences. Several future trends are anticipated to shape the landscape of screen protector manufacturing, making it more efficient, customizable, and environmentally friendly.

Integration of Advanced AI and Machine Learning

One significant trend is the integration of advanced AI and machine learning algorithms into cutting machines. These technologies can enhance the precision of cuts, predict equipment maintenance needs, and optimize production schedules. AI-driven systems can also learn from past cutting patterns to improve efficiency and reduce waste, ensuring a higher yield of usable product from raw materials.

Real-Time Data and IoT Connectivity

The ability to track the status of mobile phone screen protector cutting machines in real-time is another emerging trend. IoT connectivity allows businesses to monitor their operations closely, providing comprehensive sales tracking and performance data. This real-time data can be exported with a single click, allowing businesses to analyze and fine-tune their operations quickly.

Customization and On-Demand Production

Customization is becoming increasingly important to consumers, and future screen protector cutting machines are expected to cater to this demand more effectively. Companies like Lensun are already leading the way with machines capable of quickly producing personalized screen protectors based on customer specifications. This trend towards on-demand production allows for greater flexibility and faster response times to market changes.

Enhanced Material Options and Sustainable Practices

The variety of cutting materials is expanding, including options such as HD clear, matte, privacy, and anti-blue ray screen protectors. Future developments are likely to introduce even more specialized materials, offering enhanced protection and functionality. Additionally, there is a growing emphasis on sustainability, with manufacturers exploring recyclable materials and environmentally friendly production

processes.

Increased Automation and User-Friendly Designs

As the complexity of CAD software has made it difficult for manufacturers to source and retain skilled operators, future cutting machines are expected to feature more user-friendly designs that reduce the need for extensive training. Simplified interfaces and automated processes will enable a broader range of users to operate the machines effectively, minimizing downtime and operational disruptions.

Expansion of Compatible Device Models

Currently, screen protector cutting machines cover over 25,000 device models, with updates for new models occurring within 24 hours. This trend is set to continue, with an increasing number of devices being supported, ensuring that consumers can always find a screen protector for their latest gadgets.

Comments

Expert Tips for Maintaining Your Screen Protector Cutter

Screen protector cutters are specialized tools that ensure precise application, seamless fit, and enhanced protection for various devices.

How to Get Out Air Bubbles in a Screen Protector?

By following these guidelines, you can ensure a smooth, bubble-free screen protector application, keeping your device safe and looking great.

The Manufacturing Process- Inside a Screen Protector Factory

The manufacturing process of screen protectors combines material science, technological innovation and environmental responsibility. As technology advances, the industry is constantly addressing challenges related to sustainable development while providing device protection.

Customizing Privacy Screens: Why You Need a Smart Privacy Screen Cutting Machine

The Smart Privacy Screen Cutting Machine represents a significant advancement in privacy technology, offering precise, customizable solutions that enhance data security and user comfort across various settings.

How to Take Air Bubbles Out of Screen Protector?

By following these tips, you’ll not only remove air bubbles but also become a pro at applying screen protectors without frustration. A little patience and the right techniques go a long way toward achieving a flawless, bubble-free screen!

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.