Hydrogel Blade Cutting Machine Technology-Innovations and Future Trends

Table of Contents

Extract

Summary

Over the years, hydrogel technology has evolved, addressing early limitations such as poor mechanical properties and vulnerability to microorganisms

. This progression has led to innovations like double-network and supramolecular hydrogels, expanding their application beyond medicine to fields such as flexible electronics and mobile phone repair . The introduction of mobile phone hydrogel film cutting machines marks a notable leap in hydrogel technology application. These machines are designed for precision and efficiency, catering to the demands of modern smartphone repair shops by ensuring accurate cuts and minimizing waste. They feature advanced cutting mechanisms, such as ultrasonic blades, and integrate automation features that enhance productivity and user customization . The versatility of these machines extends their use to various industries, including medical and cosmetic fields, highlighting their broad applicability and commercial viability . Despite these advancements, the hydrogel blade cutting machine industry faces significant challenges. These include high costs, limited scalability, and mechanical limitations in robotic applications . Companies must navigate the innovator’s dilemma, balancing between sustaining innovation to improve existing products and disruptive innovation to explore new market opportunities . Open and user innovation play critical roles in addressing these challenges by leveraging external expertise and user feedback to drive technological advancements and meet evolving market needs . Future trends in hydrogel blade cutting technology are poised for transformative changes driven by both sustaining and disruptive innovations. Researchers are exploring novel hydrogel materials that are sustainable and recyclable, expanding the functional capabilities of hydrogels . Technological enhancements, such as improved automation and advanced cutting mechanisms, promise to further refine the efficiency and versatility of hydrogel cutting machines, ensuring they remain at the forefront of innovation across multiple industries .

Historical Background

The development and application of hydrogel technology have evolved significantly over the years. Initially, hydrogels were predominantly used in medical and regenerative medicine due to their unique properties, such as high water content and biocompatibility. Early hydrogel materials, often derived from natural sources like gelatin, sodium alginate, and chitosan, exhibited inferior mechanical properties, making them less suitable for in vivo tissue engineering applications

. The premature wearing out of these hydrogels often led to early degradation of the scaffold, cracks at the application site, and vulnerability to harmful microorganisms . To address these limitations, various strategies have been investigated over the past decade to enhance the mechanical resilience and applicability of hydrogel materials. These include the development of double-network hydrogels, multi-network hydrogels, click chemistry-based hydrogels, and supramolecular hydrogels . Despite these advancements, challenges remain in achieving the desired mechanical resilience, printability, shape fidelity, and biocompatibility. From 2012 to 2017, numerous patents in hydrogel technology were filed, driving significant technological advancements in the field . During this period, keyword bursts related to hydrogel innovations were frequently referenced, highlighting the forefront of research and development in this domain. Tools like CiteSpace have been utilized to identify these bursting keywords, which indicate the temporal phases of keyword prominence and provide insights into emerging trends . As hydrogel technology advanced, its applications extended beyond the medical field. The introduction of mobile phone hydrogel film cutting machines represents a significant leap in the practical use of hydrogels. These machines, designed for precision and efficiency, cater to the modern demands of smartphone repair shops, ensuring accurate cuts and reducing wastage . The compact and user-friendly design of these machines makes them ideal for small-scale repair businesses as well as large-scale production facilities, enhancing productivity and customer satisfaction . The constant evolution of technology and innovation continues to shape the hydrogel industry. In the modern workplace, businesses must stay adaptive to new developments and improvements. Disruptive technologies, which significantly change how consumers and businesses operate, and sustaining technologies, which focus on development and improvement within established markets, both play crucial roles in the ongoing innovation in hydrogel technology . The choice between these approaches is complex, as each offers unique benefits and challenges .

Technical Specifications

The Hydrogel Blade Cutting Machine integrates advanced technology to cater to the demands of modern manufacturing processes. This machine boasts a variety of features that enhance its efficiency and versatility.

Material Specifications

The machine supports cutting a range of flexible materials, including various types of hydrogels and other composites. It can handle materials with different functional properties, such as photo-responsiveness and pH-responsiveness, making it suitable for diverse applications in flexible electronics and biomedical devices

. The materials used in the hydrogel blade cutting process include both transparent and patterned films available in sizes 180 mm120 mm and 200 mm300 mm.

Blade Technology

The cutting technology features both simple and ultrasonic blades. Ultrasonic blades vibrate at high frequencies to facilitate cutting through tough and flexible materials like carbon fiber fabrics and pre-preg composites

. The machine is equipped with automatic blade change systems that allow for the detection and replacement of broken blades, ensuring continuous operation without manual intervention.

Machine Capabilities

The machine offers high-speed cutting capabilities, with average speeds ranging from 50 to 250 mm/sec. This is achieved through its integration with polyarticulated robots, which can operate autonomously to maintain desired production paces

. The robotic system is designed to adapt to flexible materials such as plastic films, 3D foam, and skin, enhancing the machine’s flexibility and scope of application.

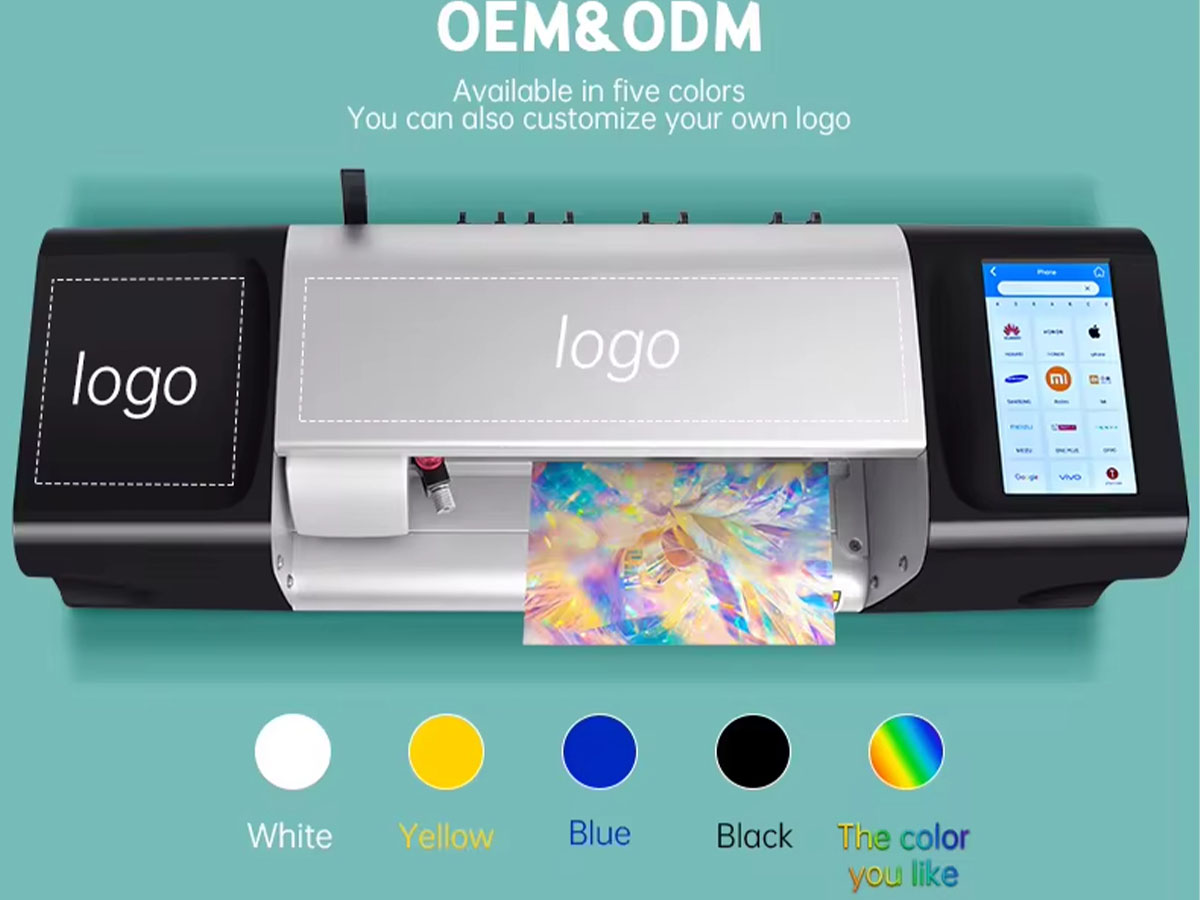

User Interface and Customization

The machine features a user-friendly interface that allows operators to easily customize the size, shape, and thickness of the hydrogel or other materials being cut. This customization is critical for producing screen protectors and other precision components required in the medical and electronics industries

. The interface is designed to be intuitive, minimizing the learning curve for new users and maximizing productivity from the outset.

Durability and Maintenance

Durability is a key attribute of the Hydrogel Blade Cutting Machine. All components enjoy a one-year warranty service, and the machine is designed to provide free technical support and parts replacement services for non-human-caused failures

. Furthermore, the machine is built with robust construction to withstand prolonged usage without significant wear and tear.

Innovations in Hydrogel Blade Cutting

Advanced Cutting Mechanisms

The development of hydrogel blade cutting technology has seen significant advancements in recent years, particularly with the introduction of the Mobile Phone Hydrogel Film Desktop Cutting Machine. This cutting-edge device is designed to meet the precision and efficiency demands of modern smartphone repair shops, ensuring accurate cuts and reducing manual trimming and wastage

. The cutting mechanism, which includes cutting blades, motor, and control systems, is crucial for accurately cutting the hydrogel film to the desired size and shape. These advancements are pivotal for both small-scale repair businesses and large-scale production facilities.

Integration of Automation Features

One of the noteworthy innovations in hydrogel blade cutting technology is the integration of automation features. These features include sensors, actuators, and control systems that automate the cutting process, such as setting cutting dimensions and speed control

. The Multi-functional Hydrogel Film Cutting Machine exemplifies this trend by offering a user-friendly interface and adjustable settings that ensure ease of use and optimal results across various applications, including medical, cosmetic, and electronic fields. Automation not only enhances precision but also significantly boosts productivity.

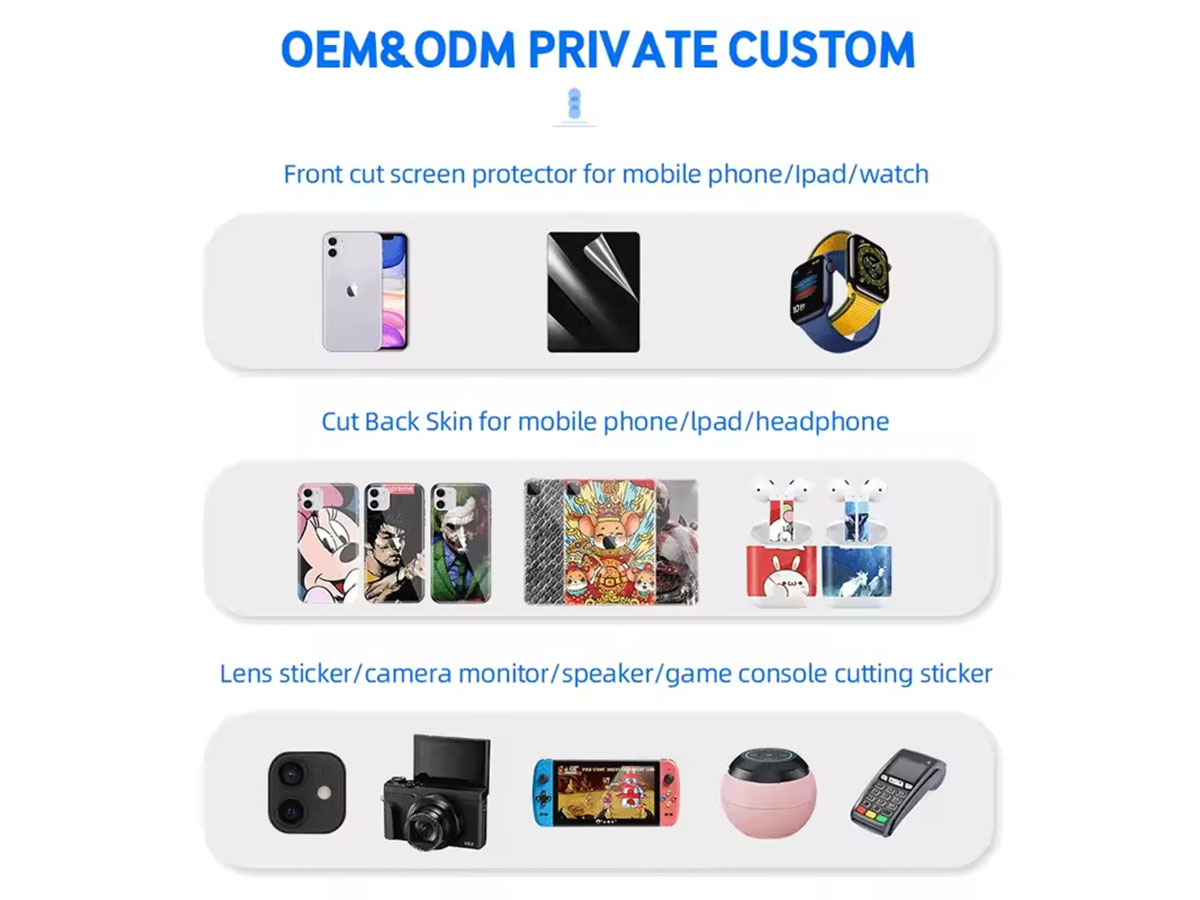

Application Versatility

The versatility of hydrogel blade cutting technology has expanded its applications beyond smartphone repair. The Multi-functional Hydrogel Film Cutting Machine, for example, is designed for professionals in diverse industries such as medical, cosmetic, and electronics, allowing for a wide range of applications with precision and efficiency

. This multifunctionality makes the machine an essential tool for professionals seeking reliable and versatile cutting solutions.

Sustaining Innovation

Hydrogel blade cutting technology embodies the principles of sustaining innovation, which focuses on consistent improvements and the introduction of upgraded products to meet evolving customer expectations. Companies in the industry invest in research and development to enhance features, quality, and functionality, thereby driving the introduction of refined products and services

. This approach ensures that existing markets continue to thrive by catering to the established customer base’s needs.

Disruptive Potential

While sustaining innovation plays a critical role, the hydrogel blade cutting industry also has the potential for disruptive innovation. Disruptive technologies often start by appealing to niche markets but eventually expand to displace established systems with new paradigms

. Innovations in hydrogel cutting machines could introduce groundbreaking changes that alter market dynamics, making products more accessible and affordable, thus catering to a broader consumer base. Understanding and harnessing the potential of these innovations can help industry leaders pivot their business models and seize new opportunities.

Future Trends

The future of hydrogel blade cutting machine technology is poised for significant advancements, driven by both sustaining and disruptive innovations. In particular, the integration of emerging materials and enhanced technological capabilities promises to transform the landscape of hydrogel applications.

Advancements in Materials

One of the most promising areas of innovation lies in the development of novel hydrogel materials. Researchers are actively exploring recyclable and sustainable hydrogels that can be used in a variety of applications, including artificial muscles and soft robots designed for safe operation around humans. Such advancements could mitigate environmental impacts and expand the functional capabilities of hydrogels

.

Sustainable Innovations

The pursuit of sustainability is a major focus within the field. For instance, the creation of polyoxometalate nanocluster-infused triple IPN hydrogels has demonstrated potential for excellent microplastic removal from contaminated water. This novel material is aimed at enhancing the environmental friendliness of hydrogels, potentially serving as a substitute for plastics in various applications

. Furthermore, the continuous upgrades in hydrogel technology, such as improved durability and recyclability, are expected to broaden their application scope and commercial viability.

Technological Enhancements

Technological improvements are also a key driver of future trends. Sustaining technologies are likely to see iterative enhancements that improve performance and efficiency. For example, advancements in camera technologies, faster processors, extended battery life, and improved user interfaces in smartphones highlight how incremental improvements can significantly enhance user experiences

.

Sustaining vs. Disruptive Innovations

While sustaining technologies focus on evolutionary improvements to existing products, disruptive technologies offer radical innovations that redefine markets. The healthcare sector, for instance, exemplifies the impact of sustaining innovation through the adoption of Electronic Health Records (EHRs) and continuous upgrades in medical imaging technologies. These advancements have streamlined patient information management and enhanced overall healthcare delivery

. On the other hand, disruptive technologies introduce new value propositions that can render existing solutions obsolete. These innovations often start in niche markets but have the potential to expand and cause significant market shifts. For example, low-end disruptions leverage lower gross profit margins and higher asset utilization to attract the least desirable customers of established companies, as seen with Korean automakers entering Western markets and Amazon disrupting traditional bookstores.

Strategic Implications

To navigate the evolving landscape of hydrogel blade cutting machine technology, organizations must adopt strategic approaches such as scenario planning and customer-centric innovation. Engaging with customers to understand their evolving needs and expectations will guide the development of new technologies, whether sustaining or disruptive. Additionally, conducting scenario planning exercises will help organizations anticipate potential futures and prepare for various contingencies

.

Applications

Hydrogels have a broad range of applications in the biomedical field due to their unique properties such as excellent biocompatibility, good mechanical characteristics, and inherent or exogenous antibacterial activity. One notable application is in the development of antibacterial hydrogels for localized applications. These hydrogels mimic the extracellular matrix with their porous structure and active groups, facilitating gas exchange, medication loading, nutrient transport, and tissue fluid absorption

. Such properties make them effective in overcoming issues related to antibiotic resistance, toxicity, and antimicrobial inefficiency typically encountered with traditional antibiotics. Furthermore, hydrogels are extensively used in tissue engineering and regenerative medicine. These applications involve the development of scaffolds that closely resemble the body’s extracellular matrix to address tissue failure and impaired self-repair. Hydrogels’ strong mechanical characteristics, biocompatibility, and biodegradability make them ideal for regenerating tissues such as nerves, cardiac muscle, cartilage, and bone. Hydrogels also play a significant role in drug delivery systems, allowing for controlled release mechanisms tailored to specific medical treatments. Various studies have demonstrated their effectiveness in delivering medications for conditions like ulcerative colitis, inflammatory bowel disease, and rectal delivery issues. For example, oral core–shell nanoparticles embedded in hydrogel microspheres have been developed for site-specific delivery of magnolol, enhancing antiulcerative colitis therapy. Additionally, hydrogels are used in wound healing applications. They exhibit advantageous biological activities, including antibacterial and anti-inflammatory properties, and promote blood coagulation and regeneration. This makes them suitable as self-healing wound dressings with hemostasis and adhesiveness for cutaneous wound healing. In the realm of advanced biomedical devices and drug delivery systems, hydrogels are integrated with bioactive molecules, enhancing their mechanical and functional properties. Innovations in this field include the development of bioactive, responsive, and conductive materials that are used in flexible, sensitive, and multifunctional devices for applications such as wearable technology, soft robotics, and bioelectronics. For instance, fully 3D-printed hydrogel actuators are being explored for use in soft robotics like jellyfish robots.

Benefits

The adoption of hydrogel blade cutting machine technology offers numerous benefits across various industries. One of the primary advantages is the enhancement of operational efficiency. By leveraging Computable Fluid Dynamics (CFD) software and high-speed cameras, companies like Kiremko have optimized the cutting process to ensure consistent quality and precision

. This innovative approach not only improves product yield but also reduces errors through systems like KnifeGuard, which monitors knife usage and condition using RFID tags. Moreover, hydrogel blade cutting machines contribute significantly to material savings. These machines are designed to rough out parts with minimal waste, allowing industries to achieve near net shape before final machining and grinding. This capability is particularly beneficial in sectors such as aerospace and automotive, where material efficiency is paramount. Additionally, the technology enhances sustainability by reducing the environmental impact associated with traditional cutting methods. For instance, the precision and repeatability of robotic waterjet systems minimize waste, contributing to more sustainable manufacturing processes. Furthermore, the incremental improvements associated with sustaining innovations in hydrogel blade cutting technology provide long-term growth benefits. These enhancements support continuous improvement and customer satisfaction by fine-tuning performance, efficiency, and added features to existing products and services. This ongoing growth ensures stability within the current market framework while addressing the immediate preferences and needs of customers.

Challenges

The development and implementation of hydrogel blade cutting machine technology face several significant challenges. Firstly, while the technology shows promise, there are inherent limitations in current methods that restrict their scalability and broader commercial application. High costs associated with noble metals or expensive carbon support materials, limited ionic and electronic conductivity, and poor mechanical flexibility are prominent issues

. Moreover, the electrochemical synthesis conditions required for these machines can be complex and challenging to scale effectively. Secondly, there is the challenge of rigidity and accuracy when using robotic applications in hydrogel blade cutting. Although robotic machining with methods like waterjet cutting offers some solutions, it still suffers from limitations in terms of rigidity and accuracy. Researchers are actively exploring novel ways to address these limitations, such as developing laser trackers and new measuring systems, as well as in-process sensing of forces to improve accuracy during high-force applications. Another obstacle is the innovator’s dilemma faced by companies in this sector. This dilemma involves the tough choice between focusing on sustaining innovation, which improves existing products and processes within established markets, and disruptive innovation, which captures new markets by embracing new technologies and adopting new business models. Overcoming this dilemma is crucial for advancing hydrogel blade cutting machine technology, as it requires a balance between incremental improvements and groundbreaking advancements. Addressing these challenges is essential for increasing the use of hydrogel blade cutting machines and opening doors to unique applications in various fields. By overcoming these limitations, the technology can achieve greater commercialization and broader acceptance in the market.

Role of Open and User Innovation

Open and user innovation play critical roles in the advancement of hydrogel technologies, enabling a more collaborative and user-centric approach to innovation. Open innovation involves leveraging external ideas and pathways alongside internal capabilities to accelerate technological advancements and market applications. This approach fosters strategic alliances and partnerships, particularly with startups and research institutions, granting access to cutting-edge technologies and expertise

. Such collaborations can drive the adoption of both sustaining and disruptive innovations, distributing development burdens and enhancing innovation capacities. User innovation, on the other hand, focuses on the contributions of end-users in the innovation process. Engaging with customers provides valuable insights into both sustaining market loyalty and exploring new segments. This feedback mechanism is crucial for understanding evolving needs and expectations, which can guide the development and implementation of new hydrogel technologies. For instance, while sustaining innovations improve existing hydrogel applications, disruptive innovations may create entirely new value propositions, such as recyclable hydrogels for artificial muscles and soft robots designed for safe operation around humans. A practical example of user-driven innovation is the continual improvement of hydrogel properties based on user feedback in various applications, from medical devices to soft robotics. This iterative process ensures that innovations are aligned with real-world requirements and user demands, enhancing the functionality and sustainability of hydrogels. By maintaining open channels for feedback, researchers and developers can make incremental improvements that provide greater value to both customers and the market. Moreover, the novel recyclable hydrogel developed by Princeton researchers exemplifies the integration of open and user innovation. The team’s approach not only addresses environmental concerns but also opens up new applications for hydrogels, potentially serving as a substitute for plastics and contributing to a more sustainable future. This type of innovation underscores the importance of user involvement and collaborative efforts in achieving significant technological breakthroughs.

Latest Innovations

Recent advancements in hydrogel blade cutting machine technology have introduced a myriad of improvements, focusing on enhancing performance, reducing operational costs, and increasing automation. One of the key innovations in this domain is the integration of polyarticulated robots, which enables precise and rapid cutting processes. These robots can be equipped with simple or ultrasonic blades, facilitating high-speed operations and offering great flexibility in usage, particularly with the capability of automatic tool changes and detection of broken blades

. Robotic blade cutting technology has also adapted to a range of flexible materials, such as skin, plastic films, coatings, 3D foam, and pre-preg composites. This is particularly useful in sectors like automotive manufacturing, where precision and cleanliness (with no chips or dust) are paramount. Another notable innovation is the development of blade tools with compliance, allowing for more effective cutting of diverse materials including “dry” composites and pre-preg composites. The high-frequency vibration of ultrasonic blades has proven to facilitate easier and cleaner cuts in these materials. Additionally, AXIOME’s automated blade change systems enhance operational autonomy, enabling the cutting cell to function independently and efficiently. These innovations, combined with the ability to integrate multiple robots in a single setup, underscore the significant strides made in optimizing the cutting process for hydrogel and other materials.

Comments

Screen Guard Machine- The Essential Tool for Tech Lovers

Screen guard machines are specialized devices designed to produce protective films and shields for electronic screens, such as those on smartphones, tablets, and laptops.

Film Cutting Machine

A film cutting machine, also known as a screen protector cutting machine, is a specialized device designed to precisely cut protective films for various electronic devices. These machines use advanced technology to ensure accurate and clean cuts, resulting in perfectly fitted screen protectors

The Environmental Impact of Flexible Hydrogel Films: A Sustainability Perspective

The environmental impact of flexible hydrogel films reveals a promising yet evolving sustainability profile, with advantages over traditional protective films in production efficiency and durability, but challenges remain in disposal and recycling that require ongoing innovation and consumer awareness.

Trumpchi GS8 2024 Navigation Instrument Tempered Glass

Protect your investment with a high-quality Trumpchi GS8 2024 Screen Protector.

Case Study- How Businesses Benefit From Professional Mobile skin cutting machine

Professional mobile skin cutting machines have become an essential tool for businesses specializing in the customization and protection of mobile devices.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.