Hydrogel Film Cutting Machine vs Tempered Glass Cutting Machine

Table of Contents

Summary

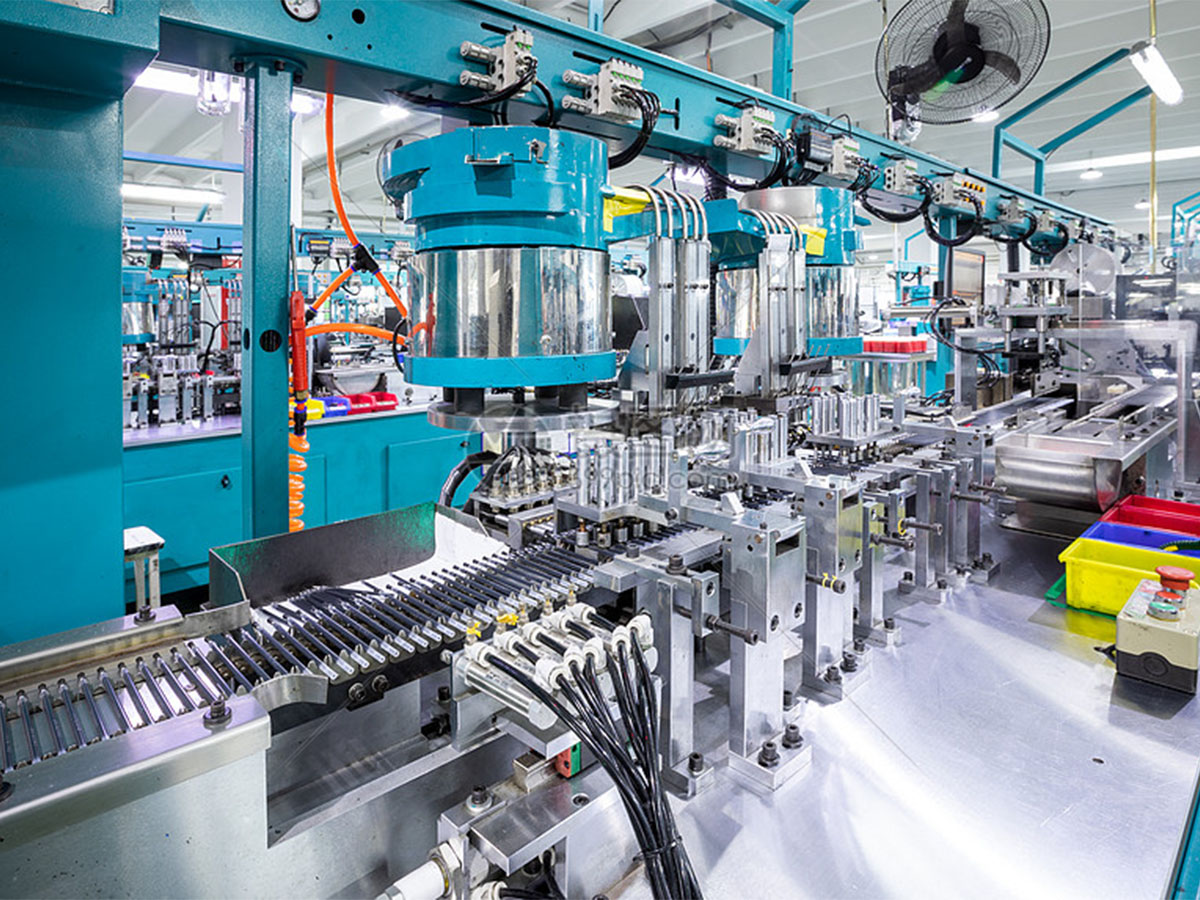

What Is a Hydrogel Film Cutting Machine?

A hydrogel film cutting machine is a specialized device designed to cut flexible and durable hydrogel films for use as screen protectors. Hydrogel, known for its self-healing properties, is ideal for protecting phones, tablets, and other sensitive electronic devices.

The process of cutting hydrogel films involves loading a roll of the film into the machine, selecting the device template from a database, and then allowing the machine to make precision cuts. Hydrogel film cutting machines are widely regarded for their ability to cut ultra-thin, flexible films that can perfectly fit the curves and edges of modern devices.

Why Businesses Use Hydrogel Film Cutting Machines

- Precision: Hydrogel cutting machines use intelligent sensors to ensure a perfect fit.

- Versatility: Capable of cutting film for various phone models and screen sizes.

- Efficiency: Machines can produce screen protectors rapidly, meeting high production demands.

How Does a Tempered Glass Cutting Machine Work?

A tempered glass cutting machine is designed to produce hardened glass screen protectors. These protectors offer superior scratch resistance but are more rigid compared to hydrogel films. The cutting process involves using specialized lasers or blades to shape the glass according to the selected device template.

Tempered glass cutting machines are built for strength and precision, cutting through layers of toughened glass while maintaining the screen protector’s integrity.

Key Features of Tempered Glass Cutting Machines:

- Laser Precision: These machines use lasers to cut through the strong, durable material.

- Durability: Tempered glass protectors are known for their toughness and resistance to cracks.

- Limited Flexibility: While tempered glass offers rigidity, it lacks the flexibility of hydrogel film, making it less ideal for devices with curved edges.

Hydrogel vs. Tempered Glass: Which Screen Protector Is Better for Your Device?

When it comes to choosing between hydrogel film and tempered glass for device protection, both have their unique strengths.

- Hydrogel Screen Protectors: These are flexible, ultra-thin, and self-healing, making them ideal for phones with curved screens or irregular surfaces. They provide excellent coverage and are less likely to crack upon impact.

- Tempered Glass Screen Protectors: These offer superior hardness, making them highly resistant to scratches. However, they are more prone to shattering when dropped.

Which Should You Choose?

- If you prefer edge-to-edge protection and flexibility, hydrogel is the best option.

- For those who prioritize durability and scratch resistance, tempered glass is a more suitable choice.

Why Hydrogel Film Cutting Machines Are Gaining Popularity in the Industry

The rise of hydrogel film cutting machines is due to several factors, all contributing to their growing market presence. These machines offer precise and rapid production of screen protectors, meeting the demands of today’s fast-evolving device market.

Advantages of Hydrogel Film Cutting Machines:

- Customization: With cloud-based templates, these machines can adapt to any new phone or tablet model quickly.

- Reduced Material Waste: The flexibility of hydrogel ensures fewer breakages during production compared to tempered glass.

- Self-Healing Properties: Hydrogel films can repair minor scratches on their own, offering longer-lasting protection.

Key Advantages of Using Hydrogel Film for Screen Protection

Hydrogel films have several key features that make them stand out as screen protectors. Here’s why hydrogel is gaining traction in the market:

- Self-Healing: Minor scratches disappear within hours, giving your screen protector a longer lifespan.

- Flexibility: Hydrogel can stretch and bend to cover even curved and irregular device screens.

- Thin and Clear: The film is virtually invisible, offering crystal-clear protection without compromising the device’s look or touch sensitivity.

Tempered Glass: Pros and Cons in the Screen Protector Market

While tempered glass protectors have long been a favorite for device users, they come with both advantages and limitations.

Pros of Tempered Glass:

- Toughness: Provides excellent protection against deep scratches and cracks.

- Premium Feel: Offers a smooth, glassy surface, closely mimicking the feel of the original device screen.

Cons of Tempered Glass:

- Shattering Risk: Tempered glass can crack under heavy impact or if dropped from a certain height.

- Lack of Flexibility: It doesn’t contour well to curved screens, leaving some areas unprotected.

How Film Cutting Machines Use Cloud Technology for Precision

One of the game-changing features of modern film cutting machines is the integration of cloud technology. This allows manufacturers to update device templates in real-time, ensuring that the latest phone models are supported.

Benefits of Cloud Technology:

- Up-to-Date Templates: Device manufacturers constantly release new models, and cloud integration ensures the film cutting machine has access to the latest designs.

- Remote Access: Businesses can monitor and control machines remotely, ensuring a seamless and efficient workflow.

- Error Reduction: Cloud integration allows machines to pull data directly from device manufacturers, reducing the risk of cutting errors.

Comparing Costs: Hydrogel vs. Tempered Glass Production

When considering the production costs between hydrogel film and tempered glass, several factors come into play.

- Hydrogel Film Production: Hydrogel film is cheaper to produce in bulk due to its flexibility and lower material costs. Additionally, the cutting process generates less waste, as the film is less prone to breakage.

- Tempered Glass Production: Tempered glass production is more expensive due to the hardening process the glass must undergo. Cutting the glass also requires more advanced machinery, and breakage during production can drive up costs.

Final Cost Comparison:

- Hydrogel film is a more cost-effective solution for manufacturers due to lower material costs and reduced waste.

- Tempered glass, while offering superior durability, can be more expensive due to material handling and the risk of breakage during production.

How to Choose Between a Hydrogel Film Cutting Machine and a Tempered Glass Cutter

Choosing the right screen protector cutting machine depends on the type of screen protectors you plan to produce.

Factors to Consider:

- Type of Device: For curved screens, a hydrogel film cutting machine is the better choice due to its flexibility. For flat screens, tempered glass might be more appropriate.

- Production Volume: If you’re producing in bulk, consider the efficiency of the machine. Hydrogel machines generally allow faster production due to reduced material waste.

- Durability vs. Flexibility: For ultimate durability, go with tempered glass. For versatile, long-lasting protection, hydrogel is the clear winner.

Hoenter Hydrogel Film Cutting Machine: A Leader in Hydrogel Technology

The Hoenter Hydrogel Film Cutting Machine stands out in the market as a premier solution for cutting-edge screen protector production. Known for its accuracy, speed, and cloud integration, this machine can easily adapt to new device models and various film types, including TPU and hydrogel.

Hoenter Machine Features:

- Precision Cutting: The Mietubl machine ensures that every cut is perfect, even for the most delicate films.

- Cloud Integration: Stay updated with the latest device templates and features through the cloud.

- Versatility: Capable of cutting hydrogel, TPU, and clear films, making it a flexible option for businesses.

Hydrogel Film Cutting vs. Tempered Glass: Key Differences at a Glance

| Feature | Hydrogel Film Cutting Machine | Tempered Glass Cutting Machine |

|---|---|---|

| Flexibility | Highly flexible, can bend to fit curved screens | Rigid, ideal for flat surfaces |

| Durability | Self-healing but less durable | Extremely durable but prone to shattering |

| Production Costs | Lower due to less waste | Higher due to risk of breakage |

| Touch Sensitivity | Excellent | Slightly reduced with thicker glass |

| Edge-to-Edge Coverage | Perfect fit for curved screens | Limited to flat surfaces |

Comments

How to Remove Invisible Shield Screen Protector?

By following these steps, you can confidently remove and replace your Zagg InvisibleShield screen protector, ensuring your device stays protected and looking its best!

How to Start Phone Accessories Business

Starting a phone accessories business involves a multifaceted approach that combines market research, business planning, legal compliance, product selection, sourcing, branding, and effective marketing strategies.

Auto Repair Anti-scratch Film EPU Screen Protector

When comparing EPU vs TPU screen protectors, EPU protectors offer significant advantages in terms of durability, flexibility, and display clarity. They are an excellent choice for users seeking long-term protection with superior scratch resistance and a premium touch experience. However, if you prioritize affordability and basic protection, TPU protectors are still a reliable option. Ultimately, your choice should depend on your specific needs for screen protection.

Baojun 530 GPS Dashboard Tempered Glass

Our Baojun 530 GPS screen protector is designed for a perfect fit. Made with tempered glass, it offers HD clarity and an oleophobic coating.

Customizing Orders- How a Screen Protector Factory Can Meet Your Needs

The importance of customized orders in screen protector manufacturing is reflected in its ability to meet the personalized needs of consumers, while promoting the advancement of production technology and the improvement of economic benefits, but it also faces problems such as production complexity, supply chain management and logistics challenges.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

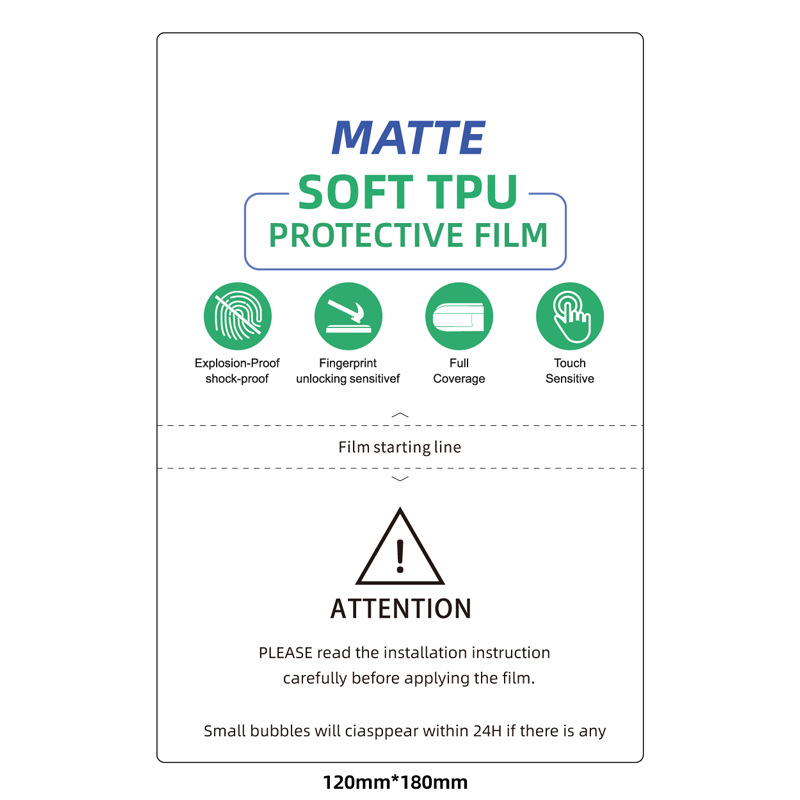

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.