The Global Supply Chain of Screen Protectors- From Factory to Store

Table of Contents

Extract

Summary

The global supply chain of screen protectors represents a complex and dynamic network encompassing various stages from raw material sourcing to consumer distribution. As an essential accessory for smartphones and tablets, screen protectors are critical for device protection, leading to a burgeoning market characterized by innovative materials and designs. The industry has gained prominence due to the rising demand for premium electronics and heightened consumer awareness regarding device maintenance, making the screen protector supply chain an important aspect of the global electronics market.

Notable for its intricate operational and strategic components, the supply chain involves multiple layers including order management, product sourcing, transportation, and logistics. Key challenges such as last-mile delivery efficiency and inventory management have become focal points for businesses aiming to enhance responsiveness and customer satisfaction in a competitive landscape. Moreover, the rise of e-commerce and shifts towards sustainable practices are reshaping traditional distribution models, reflecting broader trends in consumer behavior and environmental consciousness. Controversies in the supply chain often arise from sustainability concerns, particularly regarding the sourcing of materials and labor practices within manufacturing processes. As companies explore eco-friendly alternatives and transparent supply chains, debates persist over the balance between cost efficiency and ethical production standards. Furthermore, the rapid pace of technological advancements poses both opportunities and challenges, compelling manufacturers to adapt to innovations like 3D printing and automation while managing the complexities of global logistics. Overall, the global supply chain of screen protectors is a vital component of the consumer electronics industry, influenced by economic factors, technological innovations, and evolving consumer preferences. Its continuous development highlights the interplay between operational efficiency, sustainability, and market demands, making it a significant area of interest for both businesses and consumers alike.

Overview of the Global Supply Chain

The global supply chain for screen protectors is a multifaceted and dynamic system that encompasses various interconnected processes, from raw material sourcing to product distribution. This intricate web of operations relies on both operational and strategic supply chain management tools to ensure efficiency and effectiveness at each stage of the supply chain.

Operational Supply Chain Management Tools

Operational tools play a critical role in managing the day-to-day activities within the screen protector supply chain.

- Order Management: Facilitating the processing and fulfillment of customer orders efficiently.

- Product Sourcing & Procurement: Identifying and negotiating with suppliers for high-quality materials needed in screen protector production, significantly impacting cost and quality decisions.

- Transportation Management: Coordinating the movement of raw materials and finished products to optimize delivery times and reduce costs.

- Inventory Management: Tracking inventory levels to prevent stock-outs and manage replenishment effectively, thereby ensuring a smooth flow of products to retailers.

- Demand Forecasting & Replenishment: Using data analytics to predict customer demand, enabling timely production and inventory adjustments.

Strategic Supply Chain Management Tools

Beyond operational tools, strategic management tools aid in long-term planning and analysis of supply chain processes.

- Business Intelligence (BI) Tools: Providing insights into supply chain performance and aiding decision-making processes.

- Integrated Planning Systems (IPS) and Advanced Planning Systems (APS): Enhancing the ability to forecast demand and optimize resource allocation.

- Optimization Software Solutions: Streamlining operations to minimize costs while maximizing service levels.

- Simulation Software Solutions: Allowing businesses to model supply chain scenarios and assess the potential impacts of various strategic decisions.

Complexity of Modern Supply Chains

Today’s supply chains are characterized by their non-linear nature, with multiple networks and actors engaged in real-time transactions facilitated by digital technology

. This complexity results in a plethora of data sources, including internal metrics and external market insights, which can significantly influence supply chain operations. Furthermore, supply chain visibility enables companies to quickly respond to challenges, ensuring that they maintain a competitive edge in a rapidly changing market.

Evolving Trends and Innovations

Recent trends in the supply chain for screen protectors indicate a shift towards increased digitization and automation, allowing for greater efficiency and responsiveness. The rise of additive manufacturing, particularly 3D printing, is transforming traditional production methods, offering localized production options and reducing lead times

. Additionally, advanced performance management systems are now capable of automatically adjusting targets and managing supply chain parameters, thereby enhancing resilience against disruptions.

Raw Materials

The production of screen protectors involves a complex supply chain, starting with the sourcing of raw materials that are critical for both the protective films and the adhesives used in their manufacturing.

Adhesives and Films

Many films and adhesives used in screen protectors are designed for specific applications. To ensure optimal performance on various surfaces, manufacturers often conduct tests on surface samples to identify the most effective combinations of film backing and proprietary, water-based adhesives. If suitable combinations do not exist, manufacturers may develop new formulations to meet the demands of modern surfaces, which are increasingly reactive and challenging for adhesives to bond effectively

. To validate the durability of these adhesives and films, extensive testing is carried out. This includes subjecting them to conditions such as heat, humidity, and UV exposure in accelerated-aging chambers. This rigorous testing process ensures that the materials can withstand the rigors of shipping and long-term use without altering the product’s appearance or functionality.

Additional Protective Materials

In addition to the primary materials used for screen protectors, various other protective measures are employed during the shipping process. For example, delicate items are often interleaved to prevent friction damage. This involves placing protective barriers, such as polyethylene foam, between stacked products to absorb shock and vibration. Such materials are crushproof and can conform to a range of product shapes, providing essential cushioning during transport

.

Sustainable Sourcing

The movement towards sustainable practices in the manufacturing of screen protectors has led to the exploration of eco-friendly materials. Companies are increasingly focusing on bioplastics, organic materials, and recycled substances, alongside efforts to ensure fair labor practices and transparency in their sourcing methods

. This shift not only addresses environmental concerns but also aims to enhance the overall sustainability of the electronics accessory market.

Quality Control Measures

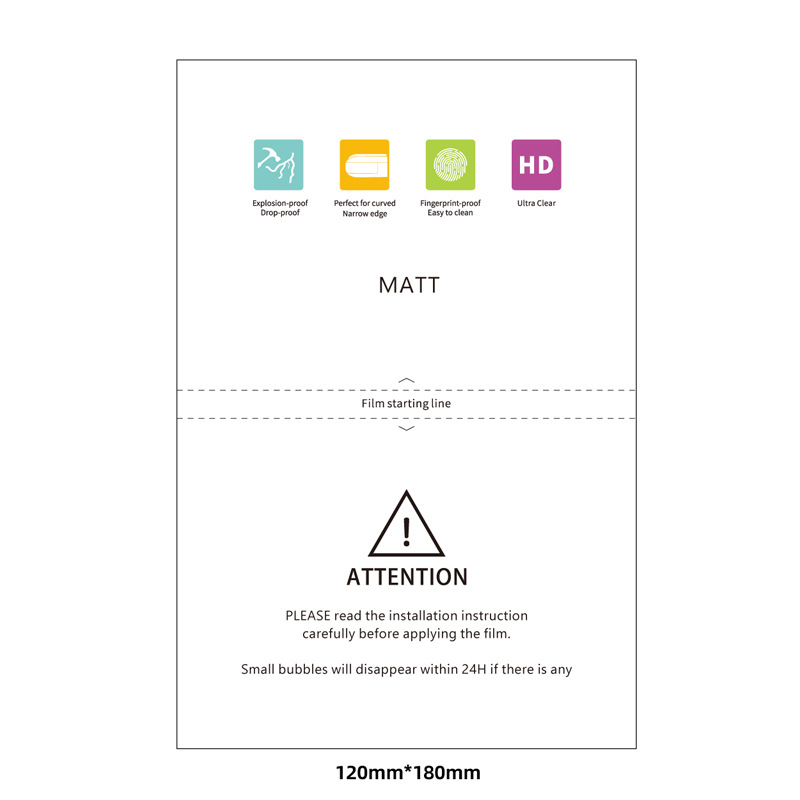

Quality control is a fundamental aspect of screen protector manufacturing, ensuring that each product meets the highest standards of performance and durability. Manufacturers, such as Strike, implement comprehensive quality control protocols throughout the entire production process, beginning with raw material inspection to verify that they meet specified criteria for thickness, clarity, adhesion, and durability

.

Inspection Procedures

The manufacturing process includes regular checks to monitor cutting accuracy and shaping precision, ensuring compatibility with specific device models. A rigorous final inspection follows, where each screen protector undergoes tests for defects and imperfections

. This multi-tiered inspection approach guarantees that only high-quality products reach consumers.

Testing Standards

Various tests are conducted to evaluate key attributes of screen protectors, including:

- Impact Resistance Testing: Simulates common drop and impact scenarios to assess the protector’s ability to absorb and dissipate energy.

- Scratch Resistance Testing: Determines the protector’s resistance to everyday objects such as keys and coins, ensuring long-lasting clarity.

- Chemical Resistance Testing: Exposes the protector to substances like oils and cleaning agents to evaluate its durability in real-world conditions.

- Oleophobic Coating Test: Assesses the effectiveness of coatings designed to repel oils and maintain a clean surface.

- Compatibility Test: Ensures that the protector fits accurately around device features such as cameras and buttons.

- UV Resistance Test: Measures the protector’s ability to withstand UV exposure, preventing yellowing over time.

- High-Temperature Resistance Test: Evaluates the protector’s performance under elevated temperatures, checking for deformation or loss of adhesion.

Compliance with Standards

Manufacturers often comply with international standards such as ISO and SGS to validate the quality and safety of their products. These certifications reassure consumers about the robustness and reliability of the screen protectors they purchase

.

Commitment to Continuous Improvement

Companies are increasingly focusing on sustainability alongside quality control. Initiatives include achieving certifications like EcoVadis™ and aiming for ISO:14001 by 2025, reflecting their commitment to both environmental responsibility and product excellence

. By maintaining rigorous quality control measures and adhering to industry standards, manufacturers foster consumer confidence and ensure the longevity of their screen protector products.

Distribution and Logistics

The distribution and logistics of screen protectors involve a multifaceted process crucial for ensuring the efficient flow of goods from manufacturers to consumers. This segment of the supply chain encompasses several vital components, including logistics management, transportation efficiency, and last-mile delivery.

Logistics Management

Logistics can be defined as the process of planning, executing, and overseeing the flow of goods across the supply chain efficiently and cost-effectively

. It is essential for businesses to manage various “moving parts” involved in logistics management, which includes supply management, warehouse infrastructure, transportation of goods, inventory control, and meeting delivery deadlines. According to the Chartered Institute of Logistics and Transport, business logistics encompasses the “seven Rs” of logistics: getting the right product, in the right quantity, in the right condition, at the right place, at the right time, to the right customer, at the right price.

Economic Influences

Economic factors significantly impact logistics operations, particularly fluctuations in fuel energy indices and rising vehicle maintenance costs. For instance, the global fuel energy price index rose from a base of 100 in 2016 to 192.37 points by April 2023, largely due to energy supply shortages and geopolitical tensions, such as the Russia-Ukraine conflict

. These rising costs affect profitability, pricing strategies, and the overall cost structure of logistics operations, potentially trickling down to consumers.

Challenges in Last-Mile Delivery

The last-mile delivery segment presents unique challenges that are critical to customer satisfaction and operational efficiency. Issues such as in-transit damage and failed deliveries directly affect the logistics process, necessitating optimized last-mile logistics strategies

. The integration of technology, such as route optimization software and real-time tracking, plays a significant role in enhancing last-mile delivery performance.

Distribution Network Optimization

Managing an effective distribution network is crucial for ensuring cost-effectiveness and responsiveness. Striking a balance between centralized and decentralized distribution centers is vital for operational efficiency

. Advanced analytics can assist in optimizing this network to enhance logistics performance. Businesses are increasingly relying on technology to automate and streamline their order fulfillment processes, thereby ensuring timely and accurate deliveries.

Future Trends and Innovations

The future of logistics in the screen protector supply chain is poised for significant transformation through advanced analytics, better connectivity, and automation technologies. Innovations such as autonomous vehicles and additive manufacturing are set to reshape warehousing and inventory management strategies

. Additionally, companies are leveraging data visibility and machine learning to improve predictive analytics, which can enhance supply chain planning and execution. However, businesses must also navigate the complexities of technology implementation, including potential resistance to change and integration issues.

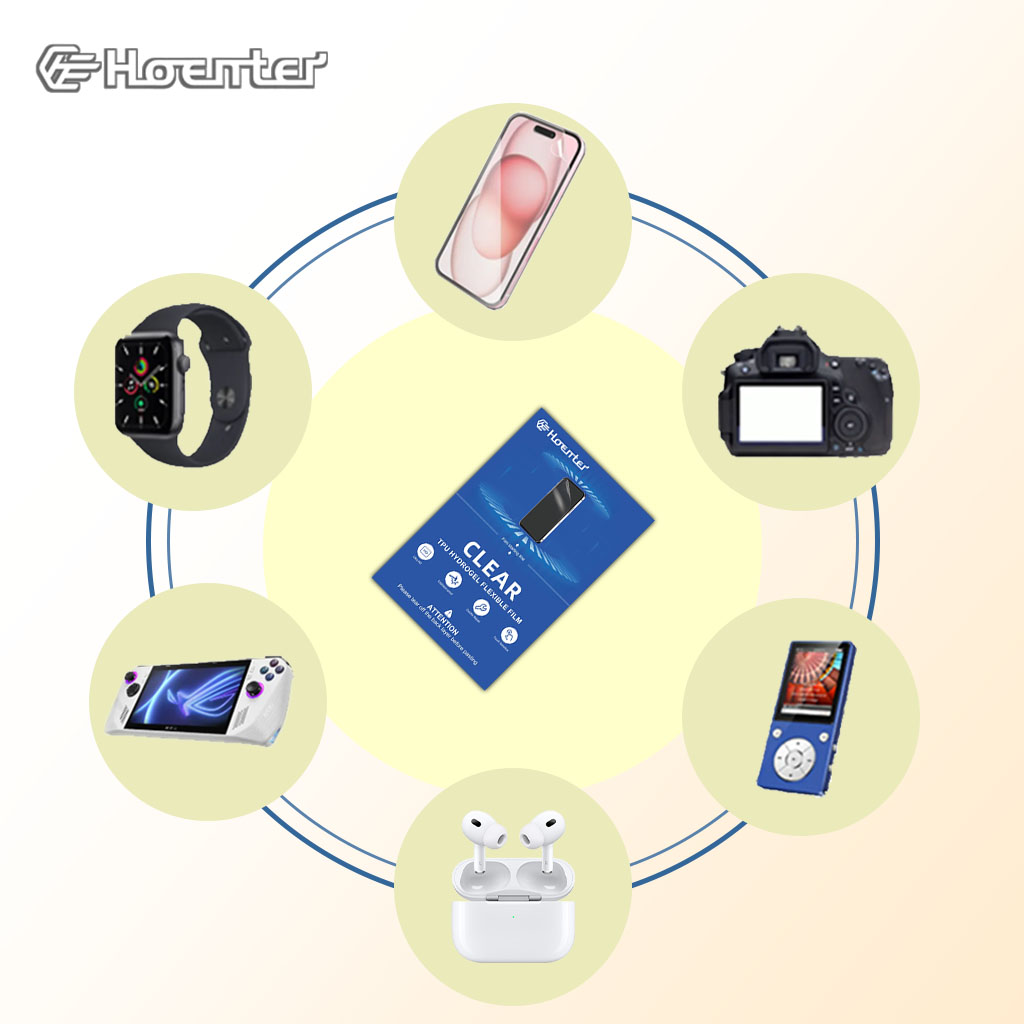

Retailing Screen Protectors

Screen protectors are distributed through various retail channels, allowing consumers to access these essential accessories conveniently. The retailing landscape includes both online and offline sales channels, each with unique characteristics and consumer preferences.

Online Sales Channels

The online marketplace has emerged as the dominant sales channel for screen protectors, primarily due to its convenience and the broad variety of options available. Consumers are attracted to e-commerce platforms for competitive pricing and the ease of doorstep delivery. Additionally, online retailers often provide comprehensive product descriptions, customer reviews, and comparison tools, enabling consumers to make informed purchasing decisions

.

Offline Sales Channels

While online sales continue to grow, offline sales channels are witnessing a resurgence. Brick-and-mortar stores, such as electronics retailers and specialty accessory shops, allow consumers to physically inspect products before making a purchase. This tactile experience, coupled with the immediate gratification of taking a product home, drives many consumers to prefer offline shopping for screen protectors

. Notably, the offline segment acquired the highest revenue share in the smartphone screen protector market as of 2021, highlighting the enduring value of physical retail environments.

Packaging and Distribution

Packaging plays a crucial role in the retailing of screen protectors. Manufacturers utilize protective packaging materials to prevent damage during transit, opting for eco-friendly solutions where possible to minimize their environmental impact

. In retail settings, attractive packaging with clear product information is vital for consumer engagement. This includes eye-catching graphics that facilitate a seamless shopping experience.

Consumer Behavior

Consumer behavior significantly influences the retail landscape for screen protectors. Price range analysis reveals that screen protectors typically range from $7 to $10, with premium options reaching higher price points

. Consumers generally view screen protectors as an investment in the protection of their smartphones, often willing to spend more for quality products that offer durability and additional features like anti-glare or privacy filters.

Market Trends and Insights

Overview of the Screen Protector Market

The global screen protector market is characterized by dynamic growth driven by evolving consumer preferences and advancements in technology. This market is thriving amid a surge in demand for luxury goods and the associated high costs of premium smartphones. Features such as LED displays and anti-glare properties are particularly appealing to consumers, especially millennials, who prioritize both aesthetic appeal and functionality in device protection solutions

.

Material Segmentation

The market is segmented by materials, including tempered glass and oleophobic coatings, each designed to meet specific consumer needs. Companies such as Gadgetshieldz are innovating in this space, offering a range of products tailored for devices like the iPhone 12 family

. The increasing concerns over eye health and the risk of retinal damage further drive demand for protective accessories that also address these health issues.

Adoption Lifecycle and Regional Insights

The market report on screen protectors outlines the adoption lifecycle, illustrating various stages from innovators to laggards, with different adoption rates observed across regions. This analysis helps companies tailor their growth strategies based on market penetration and key purchasing criteria, as well as price sensitivity among consumers

.

Competitive Landscape and Company Strategies

To enhance market presence, companies are employing strategies such as mergers and acquisitions, strategic partnerships, and geographical expansion. Key players in the market include ZAGG, OtterBox, and BELKIN, each offering distinct products and services aimed at different consumer segments. For instance, AGC Inc. specializes in flexible, scratch-resistant glass under the Dragontrail brand, while BodyGuardz offers a variety of screen protectors for multiple devices

.

Future Development Prospects

Looking ahead, the screen protector market is expected to witness substantial growth due to rising disposable incomes and heightened consumer awareness regarding device protection. The projected market size and volume forecasts for 2024 to 2034 suggest that companies must continue to innovate and adapt their strategies to meet the changing needs of consumers across various regions, including North America, Asia Pacific, and Europe

.

Comments

How to Repair Water Damaged Phone

Remember, while these steps can help save your water-damaged phone, prevention is always better than cure.

Volkswagen Viloran 2022 Navigation GPS Tempered Glass

Get the best 2022 Viloran Tempered Glass screen protector. Ultra-clear and designed to maintain the touch sensitivity of your navigation display.

Achieving a Perfect Fit: Tips for Using Your Screen Protector Cutter

“Achieving a Perfect Fit: Tips for Using Your Screen Protector Cutter” is a comprehensive guide designed to help users understand the nuances and best practices involved in using screen protector cutting machines.

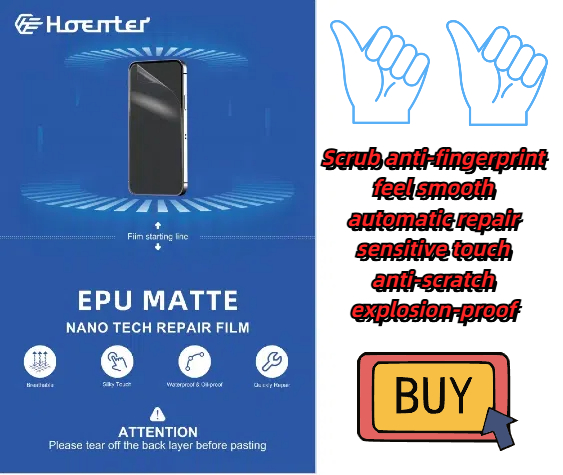

Wholesale Self Healing EPU Matte Screen Protector

Looking for self healing screen protectors wholesale? Our EPU matte film offers unbeatable protection and clarity for your customers’ devices.

EPU vs. TPU Screen Protectors: The Ultimate Showdown for Your Phone’s Display!

Choosing between EPU and TPU screen protectors? Learn the differences in self-healing to find the perfect protection for your phone’s display.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.