Maximize Your Efficiency-Tips for Using a Mobile Screen Protector Machine

Table of Contents

Summary

The topic encompasses a broad range of elements from the history and evolution of screen protectors, types of machines available, key features to consider, and step-by-step instructions for optimal use. With roots tracing back to the late 20th century and a significant evolution during the rise of personal digital assistants (PDAs) in the late 1990s, screen protectors have become essential accessories for modern mobile devices, including smartphones and tablets.

Mobile screen protector machines have revolutionized the application process, offering various types such as manual, semi-automatic, fully automatic, rotary die cutting, and hydrogel film cutting machines. Each type caters to different scales of production and customization needs, making them suitable for diverse users from small businesses to large enterprises. Key features to look for in these machines include precision cutting, material versatility, automation, waste reduction, and properties like transparency and anti-glare.

Despite the efficiency and precision offered by these machines, challenges such as wear and tear of components, systemic errors during upgrades, and managing installation issues like bubbles remain prevalent. Proper maintenance, detailed instructional materials, and a systematic approach to application can mitigate these issues and ensure high-quality results. Moreover, the market faces significant competition and the proliferation of counterfeit products, necessitating continuous innovation and quality control to maintain consumer trust and market position.

Looking forward, the industry is poised for growth driven by innovations in materials and technology, such as self-healing coatings and advancements in display technologies like foldable screens. The integration of AI, the advent of 5G, and the expansion of the Internet of Things (IoT) are expected to further enhance the market for mobile screen protectors and related machinery. Government initiatives promoting digital technology adoption in regions like Asia Pacific also play a crucial role in stimulating local markets and attracting global investments.

History

The development of mobile screen protectors has roots tracing back to the late 20th century. The first screen protector was designed and patented by Herbert Schlegel in 1968, initially intended for use on television screens. This early innovation was prompted by the need to protect the fragile glass surfaces of CRTs (cathode ray tubes), which were the predominant display technology at the time. Notably, CRTs themselves had evolved from the work of Karl Ferdinand Braun in the late 1890s and early 1900s, further developed by Boris Rosing and commercialized in the 1920s. The necessity for screen protectors grew significantly with the advent of personal digital assistants (PDAs). These devices, which gained popularity in the late 1990s and early 2000s, often utilized styluses for input. The frequent use of styluses posed a risk of scratching the sensitive LCD screens, which led to the introduction of screen protectors in the mobile device market.

Throughout the 1960s and 1970s, efforts to improve the durability of CRTs included innovations to make them more resistant to implosions. For instance, Owens Illinois patented an “implosion resistant cathode ray tube” in 1966. These enhancements reduced the need for additional protective layers, laying the groundwork for more resilient screen technologies.

In the contemporary era, screen protectors have become an essential accessory for a wide range of mobile devices, including smartphones and tablets. The rise of smartphones, particularly driven by technological hubs like China, has led to a thriving market for screen protectors. Chinese manufacturers have continually introduced new products, contributing to significant growth in the industry. Advances in materials science have also led to the development of more sophisticated oleophobic coatings, which enhance durability and ease of maintenance.

The global COVID-19 pandemic had a notable impact on the screen protector market, causing supply chain disruptions and a temporary decrease in demand. However, the market has shown resilience, with demand returning to pre-pandemic levels. As technology progresses, future trends in screen protector technology are likely to include self-healing coatings and improved longevity, ensuring continued innovation in the field.

Types of Mobile Screen Protector Machines

Mobile screen protector machines come in various types, each catering to specific needs and preferences of users. These machines are primarily designed to produce screen protectors efficiently and with high precision. Here, we explore the different types of mobile screen protector machines available on the market.

Manual Cutting Machines

Manual cutting machines are the most basic type, requiring significant user involvement for operation. These machines often come with templates and cutting tools that users must align and operate by hand. While they are cost-effective and suitable for small-scale production, they lack the efficiency and precision of automated machines.

Semi-Automatic Cutting Machines

Semi-automatic cutting machines offer a middle ground between manual and fully automated systems. These machines usually require some user input for setup and alignment but handle the cutting process automatically. They offer better consistency and efficiency compared to manual machines, making them a good choice for medium-scale operations.

Fully Automatic Cutting Machines

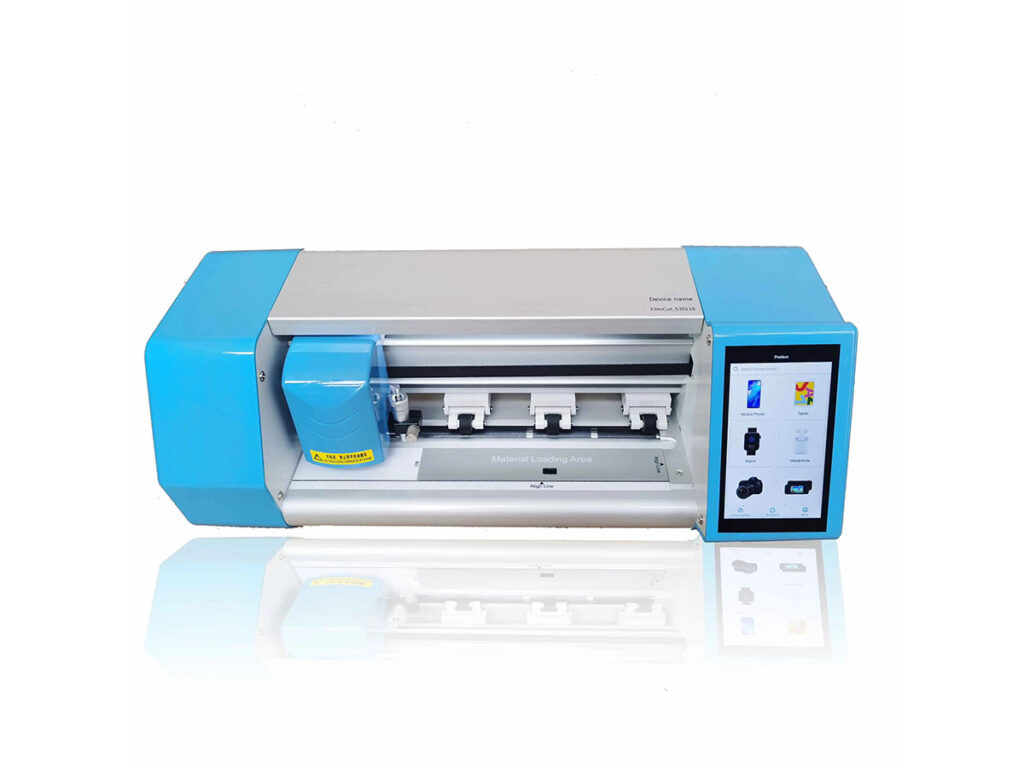

Fully automatic cutting machines, such as the upgraded versions from the MTB-CUT 180T, are designed for high efficiency and precision. These machines feature large, touch-sensitive displays that allow users to navigate through the customization process with ease. The interfaces are intuitive, and the performance is optimized for faster response and greater stability. They can handle a wide variety of mobile phone models, thanks to extensive and constantly updated compatibility databases.

Rotary Die Cutting Machines

Rotary die cutting machines are highly specialized and efficient, making them ideal for large-scale production. These machines ensure consistency by cutting each protector identically and can handle multiple layers of material simultaneously, significantly reducing production time and costs. They are known for their precision, capable of making complex cuts for devices of various shapes and sizes, and minimize waste by utilizing as much of the material as possible. Additionally, the automation of this process allows for greater production volumes and reduced labor costs.

Hydrogel Film Cutting Machines

Hydrogel film cutting machines are another advanced option, often used in professional settings such as start-ups, chain stores, and mobile phone repair shops. These machines include a comprehensive database of mobile phone and tablet models, which is regularly updated to include the latest devices. Users can create screen protectors for a wide range of devices, including smartphones, tablets, and smartwatches. These machines often come with multiple features, including the ability to customize logos through OEM services and receive free updates and technical support.

Each type of mobile screen protector machine has its own advantages and is suited for different scales of production and levels of customization. Whether you’re a small business or a large enterprise, there’s a machine that fits your needs.

Key Features to Look For

When selecting a mobile screen protector machine, it’s essential to consider several key features that can significantly impact both the quality and efficiency of the production process. Understanding these features will help you make an informed decision and maximize the benefits of your investment.

Precision Cutting

One of the most critical features to look for is the machine’s precision cutting capability. Advanced cutting technologies, such as laser or CNC (Computer Numerical Control) cutting methods, are essential for producing custom-cut screen protectors that fit the specific dimensions of the device’s screen perfectly. These technologies ensure precise cutouts for sensors, buttons, and front-facing cameras, providing a flawless fit and optimal protection.

Material Versatility

The ability of the machine to handle a variety of materials is another important factor. Machines that can cut materials like PET, TPU, and tempered glass are highly versatile and can meet different market demands. For instance, rotary die cutting machines are known for their ability to cut multiple layers of material with high precision and efficiency, making them suitable for producing screen protectors for various devices.

Automation and Efficiency

Automation is crucial for increasing production volumes and reducing labor costs. Look for machines that can automate the cutting process to enhance efficiency and consistency. Rotary die cutting machines, for example, offer high-speed production and can perform additional operations such as laminating and embossing, which add value to the screen protectors.

Waste Reduction

Efficiency isn’t just about speed; it’s also about minimizing waste. Machines that optimize material usage can significantly reduce production costs. Rotary die cutting machines excel in this area by utilizing as much of the material as possible, ensuring that waste is kept to a minimum.

Transparency and Anti-Glare Properties

Advanced features like transparent coatings and anti-glare innovations are becoming increasingly important. Transparent coatings ensure optimal clarity and touch sensitivity, preserving the device’s original display quality. Anti-glare properties reduce reflections and glare, enhancing screen readability in various lighting conditions and providing a more comfortable user experience.

Durability and Protection

Finally, consider the durability and protective qualities of the screen protectors produced. Tempered glass screen protectors, for example, are highly durable and offer superior protection against impacts and scratches. They maintain the clarity and feel of the device’s original screen, making them a preferred choice for many users. By focusing on these key features, you can choose a mobile screen protector machine that not only meets your production needs but also delivers high-quality, reliable screen protectors for a wide range of devices.

Materials Used in Screen Protectors

Mobile screen protectors come in a variety of materials, each offering unique benefits tailored to different user needs and device types. Understanding these materials helps in selecting the optimal screen protector for durability, clarity, and functionality.

PET Film

PET (Polyethylene Terephthalate) film screen protectors are known for their light- weight and thin construction. They are a cost-effective option, providing basic scratch protection and minimal impact resistance. PET protectors are made by stretching a thin film over the screen and applying an adhesive layer. They offer good light transmittance (above 90%) and an anti-glare surface, making them suitable for everyday use. However, PET screen protectors might not cover the entire screen on devices with curved edges.

TPU Screen Protectors

TPU (Thermoplastic Polyurethane) screen protectors provide excellent impact protection and are flexible, making them less prone to cracking or shattering. This material is chemically treated to enhance properties such as scratch resistance, oil and grease resistance, and elasticity, giving it a ‘self-healing’ capacity that allows it to retain its original form after light impacts. TPU protectors are typically a step above PET types in terms of durability and command a slightly higher price.

Tempered Glass Screen Protectors

Tempered glass screen protectors are the toughest and most expensive type. They offer superior protection with multiple layers of solid materials, including a shock-absorbent silicone sheet, a layer of PET film, tempered glass, and an oleophobic coating to repel oils and smudges. This combination provides excellent scratch and impact resistance, maintaining the screen’s clarity and touch sensitivity.

Nano Liquid Screen Protectors

Nano liquid screen protectors use a liquid solution that creates a thin, invisible layer on the screen surface. They offer scratch resistance and may have self-healing properties for minor scratches. These protectors form a chemical bond with the screen to provide enhanced protection and are compatible with various display technologies.

Hydrogel Screen Protectors

Hydrogel is a type of plastic that is rubbery and processed to be more scratch-resistant than PET screen protectors. It is elastic and does not crack easily, offering excel- lent protection with the added benefit of self-healing properties for minor scratches. Hydrogel screen protectors can be tricky to apply but provide maximum protection for the device.

By understanding the properties of these different materials, users can make in- formed decisions about which screen protector best suits their needs, ensuring long-lasting protection and functionality for their devices.

Step-by-Step Guide to Using a Mobile Screen Protector Machine

Using a mobile screen protector machine can significantly simplify the process of applying a screen protector to your device, ensuring a precise and bubble-free installation. Here is a step-by-step guide to help you use a mobile screen protector machine efficiently.

Step 1: Gather the Necessary Tools

Before starting, ensure you have all the essential tools ready:

Step 2: Prepare the Screen

Clean the device’s screen thoroughly with a microfiber cloth or cleaning solution to remove any smudges, fingerprints, or dust. It’s crucial that the screen is spotless to avoid bubbles during the installation process.

Step 3: Set Up the Machine

Turn on the mobile screen protector machine and ensure it is in good working condition. The latest models come with a large, touch-sensitive display, making the navigation through the customization process intuitive and user-friendly.

Step 4: Select Your Device Model

Utilize the machine’s extensive compatibility database to select the model of your device. The database includes dimensions and specifications for a wide variety of mobile phone models, which are regularly updated to include the latest devices on the market.

Step 5: Choose Your Screen Protector Type

Depending on your preference, select the type of screen protector you want to apply. Options typically include matte, privacy, self-healing, UV, and anti-glare screen protectors.

Step 6: Align the Screen Protector

With the plastic film still on the protector, align it perfectly onto your phone’s screen. Ensure the screen protector is centered over the display, especially if your phone has a curved edge at the sides of the screen.

Step 7: Tape the Screen Protector to the Phone

Use guide stickers or Scotch tape to secure the screen protector to the device. This helps in maintaining the alignment as you proceed with the installation. Apply the tape to the sides, ensuring that the protector can be flipped on and off the screen like a book.

Step 8: Apply Gentle Pressure

Carefully position the exposed adhesive side of the screen protector onto the screen. Apply gentle pressure in the center of the protector and allow it to adhere naturally. The adhesive should start spreading across the screen as you press down. Use a card or squeegee to smooth out any bubbles or creases, working from the center towards the edges.

Step 9: Remove Bubbles

If you notice any bubbles trapped under the screen protector, do not panic. Small bubbles will often disappear on their own within a day or two. For larger bubbles, gently lift the protector from one corner using the card or squeegee and reapply it, ensuring a smoother installation. Use the card or squeegee to push out any trapped air as you go.

By following these steps, you can achieve a flawless and professional installation of your screen protector using a mobile screen protector machine. Remember, patience and attention to detail are key to ensuring your device’s screen is securely protected.

Common Challenges and Solutions

When using a mobile screen protector machine, various challenges can arise, affecting the overall efficiency and quality of the output. This section outlines some common issues and their respective solutions to ensure optimal performance.

Wear and Tear of Components

Over time, certain components of the machine, such as the rubber strip, may experience wear and tear, affecting the cutting accuracy. Regular maintenance, including timely replacement of worn-out parts, is crucial. Users can refer to instructional videos or manuals that provide step-by-step guidance on how to replace these components efficiently.

Systemic Errors During Upgrades

One significant challenge users might encounter is systemic errors during upgrades. For example, upgrading the MTB-CUT M188 screen protector machine without network or power can lead to operational failures. To mitigate this issue, it is essential to ensure that the machine is connected to a stable power source and network before initiating any upgrades. In case of failure, reinstalling the firmware may be necessary to restore the machine’s functionality.

Installation Challenges

Applying a screen protector flawlessly can be tricky, even though the process is straightforward in theory. Many users struggle due to vague instructions that often accompany screen protector kits. To address this, detailed and clear instructional materials, including video tutorials, can be extremely helpful. Following a meticulous step-by-step process can minimize errors and ensure a smoother installation experience.

Managing Bubbles

Trapped air bubbles under the screen protector are a common issue that many users face. Small bubbles generally disappear on their own within a day or two, but larger bubbles can be more problematic. To manage these, users should gently lift the protector from one corner and reapply it, using a card or squeegee to smooth out any bubbles from the center towards the edges.

Material Identification

Another challenge involves the identification of cutting materials. Different degrees of blade wear can cause varied effects even when using the same cutting parameters. Therefore, it is advisable for users to routinely check the condition of the blade and make necessary adjustments to maintain consistency in cutting accuracy.

DIY Repairs

In some cases, DIY repairs can be a viable option if the necessary parts are available and the user is adept with tools. Covering the screen with clear packing tape before attempting repairs can help protect the screen from additional damage during the process.

By understanding and addressing these common challenges, users can maximize the efficiency of their mobile screen protector machines and ensure high-quality results.

Tips for Maximizing Efficiency

The use of mobile screen protector machines has revolutionized the production and application of screen protectors, allowing for increased precision, efficiency, and quality.

Consistency and Precision

One of the key advantages of using these machines is the ability to ensure every screen protector is cut identically, guaranteeing a consistent product for end users. High-precision cutting mechanisms allow for ultra-accurate fitting of each hole and edge, ensuring impeccable alignment with device components. This level of precision minimizes the risk of misalignment, which can compromise the effectiveness of the screen protector.

Material Utilization and Waste Reduction

Rotary die cutting machines are particularly effective in reducing material waste by optimizing the usage of the raw material. They can cut multiple layers of material

at once, thereby minimizing excess waste and making the production process more sustainable and cost-effective. This waste reduction also contributes to a lower environmental impact and better resource management.

Automation and Mass Production

Automation is another significant factor that enhances efficiency. These machines can be easily integrated into automated production lines, allowing for greater production volumes with reduced labor costs. This capability is crucial for manufacturers aiming to meet high demand without compromising on quality. Furthermore, features like automatic film feeding and touch-sensitive operation streamline the production process, making it more user-friendly and less time-consuming.

Material Innovation and Durability

Tempered glass is widely used in screen protectors due to its superior durability, excellent clarity, and enhanced scratch resistance. The tempering process, which adds a layer of compression to the glass surfaces, significantly enhances its performance and longevity. The use of oleophobic coatings further improves durability by preventing the build-up of fingerprints and smudges, maintaining the protector’s effectiveness and aesthetic appeal.

Quality Control and After-Sales Support

To maintain high standards, it is important to implement rigorous quality control measures. Each screen protector should undergo thorough inspection before being shipped out to ensure it meets the required specifications and standards. Additionally, offering professional after-sales support, including free technical support and replacement parts for non-human damage within a specified period, can greatly enhance customer satisfaction and loyalty.

Efficient Work Environment

Setting up an ideal working area is crucial for achieving professional-quality results. Choose a clean, well-lit space free from dust particles, and ensure that your tools and materials are organized and easily accessible. Properly cleaning the screen of your device before applying the protector is also essential to avoid bubbles and ensure a flawless application.

By following these tips, manufacturers and technicians can maximize the efficiency of their mobile screen protector machines, resulting in high-quality products that meet the demands of today’s tech-savvy consumers.

Common Mistakes and How to Avoid Them

When learning how to apply a screen protector, it’s crucial that you avoid making any of these common mistakes which could compromise its ability to protect your device. Firstly, failing to work in a clean environment free from dust may cause particles to become trapped beneath the screen guard leading to ugly air pockets and decreased visibility. This not only makes your gadget less attractive but also interferes with smooth touch operation.

Additionally, rough handling or applying excessive pressure can damage the protector and diminish its adhesive properties, making it less effective over time. Therefore, always handle the screen protector gently and avoid pressing too hard during installation.

To ensure that your screen protector remains sticky and effective, regular maintenance is key. Clean the protector with appropriate materials to remove fingerprints and smudges, which can affect its adhesiveness. By taking these precautions, you can maintain the functionality and aesthetic appeal of your device’s screen protector.

Benefits of Using a Mobile Screen Protector Ma- chine

Using a mobile screen protector machine offers several benefits that can significantly enhance both the efficiency and quality of screen protector application.

Cost-Effectiveness

While the initial investment in a mobile screen protector machine can be substantial, it often proves to be cost-effective in the long run. The machine minimizes the likelihood of errors, reducing the need for multiple screen protectors and decreasing waste.

Additionally, the speed and efficiency of the machine can lead to higher throughput, enabling businesses to serve more customers in less time.

Precision and Accuracy

One of the most significant benefits of using a mobile screen protector machine is the precision and accuracy it provides. These machines are designed to align the screen protector perfectly with the device’s display, minimizing the risk of misalignment. This ensures that the screen protector covers the entire surface area without leaving any gaps or bubbles, leading to a flawless finish that is difficult to achieve manually.

Time Efficiency

Mobile screen protector machines can dramatically reduce the time required to apply a screen protector. Traditional methods of applying screen protectors can be time-consuming and often require multiple attempts to achieve the perfect fit. With a screen protector machine, the process is streamlined and efficient, allowing for faster application. This is particularly beneficial for businesses that need to apply screen protectors on multiple devices, saving both time and labor costs.

Consistency

Another advantage of using a mobile screen protector machine is the consistency it offers. When applying screen protectors manually, the outcome can vary significantly from one application to another. Machines, on the other hand, are programmed to apply the protector in the same manner every time, ensuring a consistent, high-quality result. This consistency is crucial for businesses that prioritize maintaining a high standard of service.

Enhanced Protection

Screen protectors applied using a machine are less likely to have bubbles or dust trapped underneath, which can compromise the protective layer’s effectiveness. A perfectly applied screen protector is more likely to offer optimal protection against scratches, cracks, and other forms of damage, thereby extending the device’s lifespan and maintaining its visual and functional appeal.

Professional Appearance

The use of a mobile screen protector machine can enhance the professional appearance of the service provided. Customers are more likely to trust and value a service that utilizes advanced technology to ensure the best possible outcome. This can lead to higher customer satisfaction and repeat business.

Minimal Touch Sensitivity Interference

Proper application of screen protectors using a machine ensures that the touch sensitivity of the device is minimally affected. A machine-applied screen protector is more likely to adhere seamlessly to the screen, preserving the device’s original touch responsiveness and user experience.

Potential Drawbacks and Limitations

The market for mobile screen protector machines is not without its challenges. One significant issue is the intense competition among numerous manufacturers, which has led to price wars and margin pressures. This competitive landscape makes it difficult for companies to differentiate their products, limiting profit margins and hindering market expansion. Moreover, counterfeit and low-quality products flood the market, undermining consumer trust and affecting sales of genuine, high-quality protectors. This necessitates substantial investments in innovative technologies, branding, and marketing strategies to stand out in the crowded marketplace.

Another limitation is the added hassle and inconvenience perceived by some users when applying screen protectors. This can lead to reluctance to invest in such pro- ducts, particularly among users who prioritize convenience and trust in the inherent durability of their smartphone screens. Furthermore, conventional methods of implosion protection suffer from several disadvantages, such as multiple reflections of objects and lights in front of the receiver, or the penetration of dust into inaccessible spaces between the layers, which aggravate the user experience.

Additionally, the global consumer electronics market faces constraints from short product lifecycles and the proliferation of counterfeit products. Rapid technological advancements lead to shorter product lifecycles, making it challenging for manufacturers to recoup their investments. Counterfeit products not only erode brand trust but also affect revenues and can compromise user safety and security.

Companies must therefore focus on innovation, quality control, and anti-counterfeiting measures to maintain a competitive edge and protect consumer interests.

Understanding these potential drawbacks and limitations is crucial for manufacturers and consumers alike to navigate the complexities of the mobile screen protector machine market effectively.

Innovations and Future Trends

The consumer electronics industry is witnessing significant trends driven by technological advancements and innovations that are reshaping the market. One of the major trends is the rise of smart electronics integrated with artificial intelligence (AI). Continuous technological innovations are enhancing connectivity and introducing advanced features, with manufacturers incorporating AI-driven functionalities like voice assistant controls and Bluetooth connectivity to improve the consumer experience by offering convenience, interactivity, and efficiency across various electronic products.

The emergence of 5G networks, the surging popularity of smart homes, and advancements in augmented and virtual reality technologies are set to transform the increasingly digital and interconnected world, presenting numerous opportunities for the consumer electronics market to expand. The proliferation of Internet of Things (IoT) devices, such as fitness bracelets and smart home gadgets, along with rising disposable incomes and the growing popularity of smart devices, further contribute to industry growth.

Another critical area of innovation is in the smartphone screen protector market, which is experiencing robust growth due to the rising demand for smartphones glob- ally. The market is projected to reach a value of USD 63,355.08 million by 2028, with a compound annual growth rate (CAGR) of 7.96% during the forecast period. The growing usage of smartphones, particularly those with expensive-to-fix AMOLED, LED, and infinity displays, underscores the importance of screen protectors.

Innovations in display technologies, such as foldable screens seen in devices like Samsung’s Galaxy Fold and the Moto Razr, are expected to significantly advance the screen protector market.

Leading manufacturers are focusing on providing reliable and cost-effective products for protecting high-end smartphones, with a particular emphasis on tempered glass screen protectors. The U.S. smartphone screen protector market, valued at 9.90 billion in 2022, is estimated to grow at a CAGR of 6.6% from 2023 to 2030.

This growth is driven by partnerships between popular brands like Corning Inc. and Belkin International, Inc., and global smartphone brands such as Apple, Samsung, and Xiaomi, to introduce upgraded shockproof protection films and back covers. In addition to smart electronics and smartphone accessories, the consumer electronics market is also poised for growth through government initiatives and supportive policies. In the Asia Pacific region, governments in countries like China, India, and South Korea are promoting the adoption of digital technology, providing subsidies for manufacturing, and encouraging domestic production, which has stimulated the local market and attracted multinational companies to invest and establish their regional manufacturing facilities.

As consumer electronics continue to evolve, these innovations and trends are expected to drive significant growth and transformation in the industry, offering enhanced products and services to a tech-savvy global consumer base.

Comments

How to Wash a Screen Protector?

By following these simple steps, you can keep your screen protector clean and functional for as long as possible, ensuring your device remains protected and looking great.

Top Features to Look for in a Hydrogel Blade Cutting Machine

Hydrogel blade cutting machines are specialized equipment designed to precisely cut hydrogel films, which are commonly used in applications such as screen protectors for electronic devices and various medical applications.

How to Apply a Screen Protector to a Camera?

By following these steps and tips, you’ll ensure your camera lens remains protected and ready to capture stunning images. Happy shooting!

Hongqi HS9 2023 Navigation Tempered Glass

Protect your investment with a high-quality Hongqi HS9 2023 Screen Protector. Prevent scratches and damage to your new HS9’s navigation display.

Mobile Screen Protector Hydrogel Film Sheets

In an era where our smartphones are indispensable, protecting them is essential. Our Hydrogel Screen Protector Film offers unmatched protection, flexibility, and longevity. Whether you’re a distributor looking for a versatile solution or a consumer who wants the best for their device, our hydrogel film is the clear choice. It provides the perfect balance of protection, style, and innovation, ensuring your phone’s screen remains flawless for longer while delivering a superior user experience. Choose us for unparalleled quality, reliability, and eco-friendly solutions.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.