Why Every Mobile Repair Shop Needs a Intelligent film cutting machine

Table of Contents

Summary

These machines, driven by advanced technologies such as artificial intelligence and machine learning, are designed to accurately cut and customize protective films for various electronic devices, including smartphones, tablets, and laptops. This innovation addresses common challenges faced by repair shops, such as inventory management, high turnover rates, and the need for rapid service delivery, making them indispensable tools in the industry.

Mobile repair shops have evolved from providing basic services like screen repairs and battery replacements to offering more complex and diversified services, including computer repairs. This evolution has been driven by the growing ubiquity of smartphones and other electronic devices, as well as advancements in technology. Intelligent Film Cutting Machines play a crucial role in this transformation by enabling on-demand film cutting, which reduces the need for extensive inventory and minimizes material waste. The ability to provide customized protective films quickly and accurately not only improves the efficiency of repair processes but also enhances customer satisfaction by meeting the demand for precise and high-quality solutions. The integration of automation and robotics in Intelligent Film Cutting Machines has further revolutionized the mobile repair industry. These machines offer increased speed, accuracy, and efficiency, essential for handling the diverse and growing demands of the market. They also support various types of protective films, such as PE, PU, and hydrogel, ensuring that repair shops can cater to a wide range of customer needs. The adoption of such advanced tools underscores the importance of continuous learning and specialized training for technicians, as they navigate the complexities of new devices and technologies.

Despite the significant benefits, the initial investment cost for Intelligent Film Cutting Machines can be a barrier for some small businesses. However, the long-term advantages, such as reduced operational costs, increased productivity, and improved customer satisfaction, often justify the expenditure. As the industry continues to embrace technological advancements and adapt to changing consumer preferences, the market for Intelligent Film Cutting Machines is poised for substantial growth. This trend highlights the critical role these machines play in ensuring the competitiveness and sustainability of mobile repair shops in an increasingly digital and fast-paced world.

History of Mobile Repair Shops

The mobile repair industry has seen significant changes since its inception, evolving in response to advancements in technology and changing consumer needs. Initially, mobile repair shops primarily focused on basic services like screen repairs, battery replacements, and addressing water damage. However, as the ubiquity of smart- phones grew, so did the complexity and variety of services offered by these repair shops.

In recent years, the industry has experienced a noticeable shift toward in-store repair services offered by major mobile network operators. For example, T-Mobile has upgraded 500 stores across the United States to include in-store device repairs by industry-certified experts from Assurant. This expansion is T-Mobile’s first foray into in-store repairs, aimed at providing customers with fast and reliable service using manufacturer-approved parts.

The rise of mobile repair has not been confined to smartphones alone. The increasing dependence on computers and laptops, particularly in a post-COVID world, has pushed many repair shops to diversify their services to include computer repairs as well. This diversification has become a strategic necessity for repair shops looking to stay competitive and expand their revenue streams.

Moreover, the market for mobile repair has seen impressive growth. Between 2016 and 2021, product sales in mobile repair more than doubled, and the number of technicians joining the field also doubled during this period. The flexibility and rapid expansion of mobile repair services have made the industry attractive to many mechanics, particularly in an era where traditional service bays are declining.

Technological advancements have played a crucial role in shaping the mobile re- pair industry. Big data and artificial intelligence have made it easier to diagnose issues remotely, improving efficiency and reducing the need for hands-on mechanical diagnostics. Despite these advancements, repair shops still face challenges, particularly in inventory management and the need for specialized training due to the constant introduction of new devices and technologies.

The integration of automation and robotics in the repair industry, especially in tasks like film cutting, has also emerged as a significant trend. This integration offers increased efficiency, accuracy, and speed, essential for meeting the growing demand for precise and customized cutting solutions . The market for intelligent film cutting machines is expected to grow at an annual rate of 13.6% from 2024 to 2031, driven by advancements in technology and the need for high-quality production.

Importance of Efficient Tools in Mobile Repair

The mobile repair industry is constantly evolving as new devices continually enter the market. This dynamic landscape necessitates the adoption of new technologies and standards of maintenance, making continuous learning and specialized training crucial for technicians. Most cell phone repair is often conducted through trial and error because schematics and manufacturing documents are not readily available, forcing technicians to rely on their own investigative methods. This practice under- scores the need for more efficient tools that can streamline the repair process and minimize guesswork.

The repair of cell phones has become increasingly competitive due to the growing ubiquity of smartphones in daily life. Repair shops must satisfy customers’ expectations, expedite operations, and increase efficiency, often by using specialized software to manage various aspects of the business, including inventory management. Effective inventory management is crucial as repair shops handle multiple phone models and replacement parts. Any delay in acquiring the right parts can frustrate customers and result in lost business.

Quality control is another critical aspect of the repair industry, encompassing time- lines, warranties, and client communication. Ensuring high-quality repairs and timely service can significantly impact customer satisfaction and retention. Additionally, the presence of over 700 repair locations and thousands of experts highlights the importance of accessible, reliable service. Many shops offer same-day repairs, free diagnostics, and competitive pricing, with a one-year limited warranty standard on most repairs. These practices help establish trust and reliability with customers, reinforcing the importance of efficient tools and processes.

Moreover, younger generations, particularly Gens Y and Z, have distinct buying preferences that favor online transactions and show little interest in developing personal relationships with repair outlets. This demographic shift further emphasizes the need for advanced technology in mobile repair shops. Big data and artificial intelligence can aid in remote diagnostics and streamline the acquisition of necessary parts, reducing the reliance on traditional, relationship-based business models.

Intelligent Film Cutting Machines

Intelligent Film Cutting Machines represent a significant advancement in the film cutting industry, combining precision, efficiency, and automation capabilities through the use of artificial intelligence and machine learning algorithms. These sophisticated machines can accurately cut and customize film materials to specific requirements, ensuring optimal results and minimal waste. They are particularly vital for the precision cutting of protective films for electronic devices, such as screen protectors for smartphones.

Types of intelligent Film cutting Machines

Intelligent Film Cutting Machines are categorized based on the cutting technology they employ.

Laser Film Cutting Machines: Utilize laser technology to achieve precise and accurate cuts.

Blade Film cutting Machines: Use sharp blades for efficient cutting.

Waterjet Cutting Machines: Employ high-pressure water jets for cutting a variety of materials.

Ultrasonic Cutting Systems: Utilize ultrasonic waves to facilitate smooth and precise cuts. Each type offers unique advantages in terms of precision, speed, and suitability for different materials.

Applications and End-User Industries

The applications of intelligent Film Cutting Machines extend across numerous industries:

Electronics: Essential for cutting protective films for devices such as smartphones, tablets, and laptops.

Packaging: Used for cutting various packaging materials with high precision.

Automotive: lmportant for cutting materials used in automotive interiors and exteriors.

Healthcare: Utilized for cutting medical films and other healthcare-related materials.

Textiles: Emploved in the precision cutting of fabrics and other textile materials End-users of these machines include manufacturers, contract packaging companies, and service providers who seek to enhance their production capabilities, reduce costs, and improve product quality through advanced cutting solutions tailored to their specific requirements.

Technological Advancements

The technological innovations in Intelligent Film Cutting Machines include:Artificial intelligence and Machine Learning: These algorithms optimize cutting processes,improve efficiency, and minimize waste by enabling precise control and customization of the cuts.

Advanced Sensing Technologies: Such as programmable logic controllers (PLCs) and computer vision systems, which ensure precise control and optimization of the cutting processes. These advancements make intelligent Film Cutting Machines an indispensable tool in modern manufacturing, providing a high degree of customization and flexibility to meet the diverse needs of various sectors.

Technological Advances

The landscape of the Intelligent Film Cutting Machine industry is evolving rapidly, propelled by significant technological advancements. One of the key drivers behind this progress is the integration of automation and artificial intelligence (AI), which are revolutionizing various sectors including automotive, packaging, and electronics. These technological innovations are allowing companies to enhance productivity and reduce production costs while delivering precise and efficient cutting solutions.

Automation and AI Integration

Automation and AI are not just buzzwords but pivotal elements transforming the industry. By integrating machine learning and AI, companies are minimizing human errors and enhancing operational efficiency. For example, machine learning algorithms are now being employed for predictive maintenance, which utilizes historical data and real-time trends to forecast component failures. This proactive approach enables timely maintenance actions, thereby preventing system downtimes.

Platforms like the Spectare® Intelligent Platform by ISS are setting high standards in process optimization and automated quality control. These AI-driven systems optimize energy allocation, ensuring efficient use of resources while maintaining stringent quality parameters. The Spectare® platform also offers a customizable dashboard with system alerts, remote support, and usage insights, further stream- lining operations and enhancing productivity.

Industrial Internet of Things (IIoT)

The advent of the Industrial Internet of Things (IIoT) is another groundbreaking development. IIoT is enhancing interconnectedness among different machines and equipment on the shop floor, enabling more sophisticated prototype designs and incorporating specific customer feedback into new products. This interconnected environment facilitates seamless collaboration and synchronization of activities, which are crucial for achieving maximum efficiency in modern machine shops.

Robotics and Customization

The integration of robotics with automation in film cutting machines has yielded remarkable benefits, particularly in sectors that demand high precision such as aerospace and automotive manufacturing. This synergy allows for customized cutting solutions capable of performing a diverse range of tasks with speed and accuracy. The use of robotics ensures higher levels of repeatability and consistency in production, which are essential for maintaining high-quality standards. Additionally, automation helps reduce labor costs and boost productivity by accelerating the cutting processes.

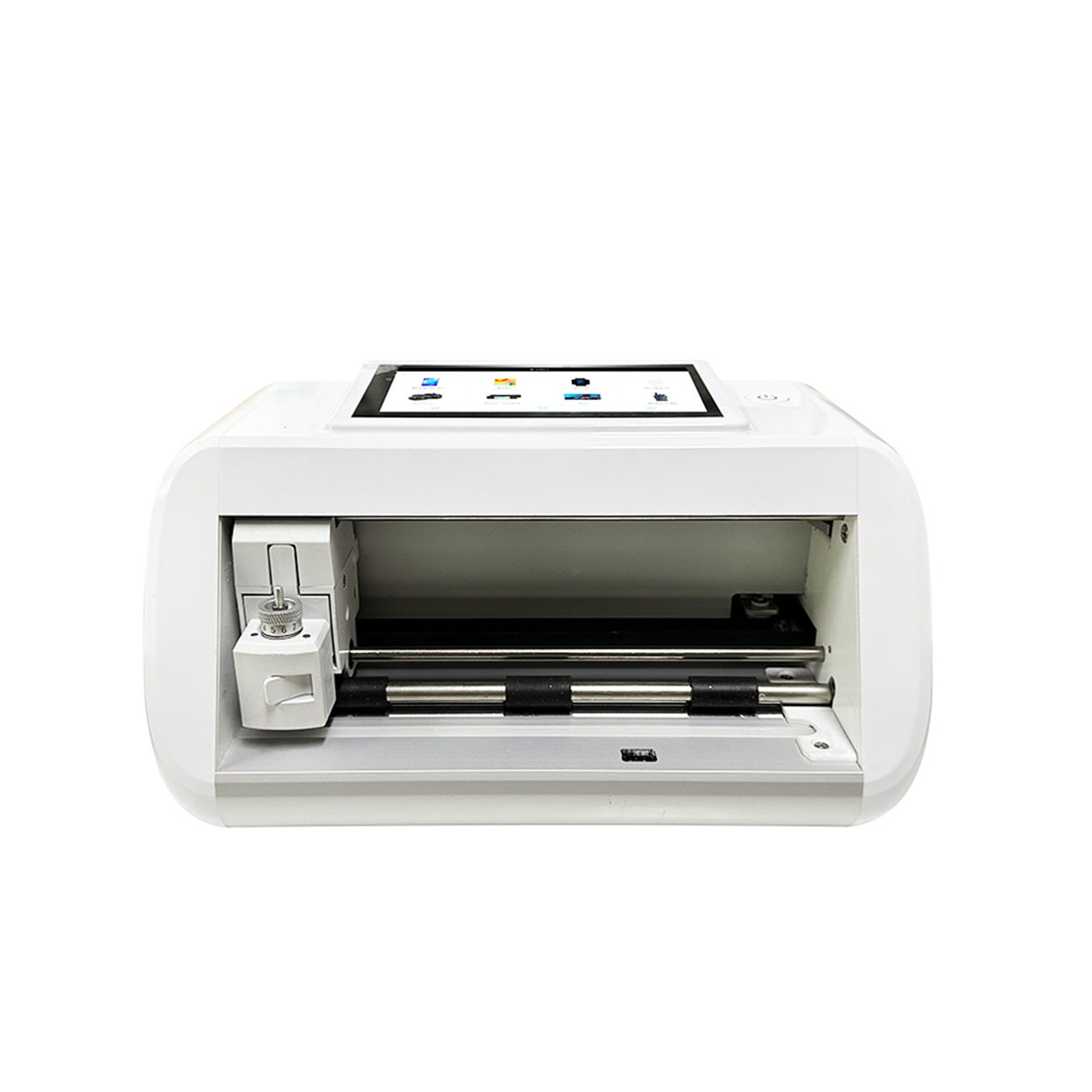

User-Friendly Features

Modern Intelligent Film Cutting Machines come equipped with advanced user-friendly features such as built-in touchscreens, Bluetooth connectivity, and app control. These machines often support offline and online versions, allowing for flexible operation modes. The automated feeding film mechanism, supported by sensors, ensures smooth and continuous operation. Furthermore, comprehensive data libraries, featuring thousands of models that update regularly, make it easier for users to access the latest specifications without the need for software downloads. These technological advances are setting the stage for a new era in industrial operations, characterized by enhanced safety, optimized processes, and reduced operational costs. As the industry continues to evolve, the Intelligent Film Cutting Machine market is poised for substantial growth, offering promising opportunities for innovation and efficiency.

Benefits of Intelligent Film Cutting Machines in Mobile Repair

Intelligent Film Cutting Machines offer numerous advantages that make them essential tools for mobile repair shops. One of the most significant benefits is the ability to alleviate inventory pressure. Traditional screen protector films often require shops to maintain a large inventory of pre-cut films for various models, which can be both costly and space-consuming. In contrast, Intelligent Film Cutting Machines enable shops to cut films on-demand according to the specific model of the electronic device, thus eliminating the need for extensive inventory.

Another key advantage is the low investment cost associated with these machines. Unlike other specialized equipment, Intelligent Film Cutting Machines are relatively affordable, making them accessible to small businesses and individual entrepreneurs. This low entry cost, combined with the machine’s potential to generate significant revenue, allows mobile repair shops to achieve profitability quickly. The versatility of these machines also contributes to their appeal. Intelligent Film Cutting Machines are designed to cut various types of protective films, including PE film, PU film, and hydraulic film, among others. This flexibility ensures that shops can cater to a wide range of customer needs, from basic screen protection to advanced explosion-proof films.

Moreover, these machines enhance the precision and efficiency of film cutting processes. By using advanced cutting solutions tailored to specific requirements, shops can improve product quality and reduce material waste. This high level of precision is particularly beneficial in ensuring that the protective films fit perfectly on the devices, thereby providing optimal protection.

Additionally, the integration of smart technology and cloud databases in Intelligent Film Cutting Machines allows for easy updates and access to the latest screen models. This ensures that mobile repair shops can stay up-to-date with the ever-evolving market of electronic devices, providing their customers with the most current and effective solutions.

Impact on Customer Satisfaction

In the mobile repair industry, customer satisfaction is pivotal to the success and sustainability of a repair shop. Implementing intelligent tools such as film cutting machines can significantly enhance customer experience and satisfaction.

Firstly, the integration of modern point of sale (POS) systems, coupled with intelligent film cutting machines, streamlines the entire repair process. These systems enable quick and accurate service delivery by reducing manual data entry and mitigating system lags, which are common issues with outdated tools. Consequently, this ensures that customers experience minimal wait times during both the check-in and check-out processes, leading to a more efficient service.

Additionally, leveraging advanced technology allows repair shops to offer personalized services. For instance, POS systems with loyalty features can store customer information such as full name, email, and phone number on key tags. When scanned, this information helps in providing a customized experience that makes customers feel valued and recognized . Moreover, automated notifications and updates integrated into the POS software keep customers informed in real-time about the progress of their repairs, further enhancing their overall experience.

Intelligent film cutting machines also contribute to maintaining high-quality service standards. These machines ensure precision and consistency in the application of protective films, which not only protects customer devices but also enhances the perceived value of the service provided. High standards of quality control, including thorough inspections and professional after-sales support, reinforce customer trust and satisfaction.

Moreover, customer communication is improved through digital channels, ensuring that clients are always updated about the status of their repairs and any additional costs. This transparency builds trust and ensures that customers feel their needs are being met effectively. The proactive collection and management of customer feedback through integrated review systems also allow repair shops to address any concerns promptly, maintaining a positive online reputation which is crucial for attracting new customers in the digital era.

Operational and Financial Impact on Mobile Re- pair Shops

The landscape of mobile phone repair shops is evolving rapidly due to increased competition and the ubiquity of smartphones. This evolution necessitates the adoption of advanced technology and strategic business practices to stay competitive and profitable.

Diversification of Services

Owning a cell phone repair shop should not be limited to just repairing cell phones. To remain competitive, repair shop owners need to explore other streams of revenue, such as computer repairs and the sale of phone accessories like cases and chargers. The flexibility offered by modern repair shop software makes it relatively simple to add new services. This diversification can help repair shops attract a broader customer base and generate additional revenue.

Leveraging Technology

Implementing a robust Point of Sale (POS) system tailored for cell phone stores can streamline various operations. Such a system can assist in managing inventory, tracking sales, and generating custom reports, all of which contribute to smoother operations and increased efficiency. A POS system with integrated repair software, real-time inventory tracking, and customer relationship management (CRM) features can significantly reduce the burden of manual data entry and inventory management.

Inventory Management

Effective inventory management remains a critical challenge for cell phone repair shops. With many phone models and replacement parts to handle, precise inventory management is crucial to avoid delays in repairs and ensure customer satisfaction. Automated inventory management systems can track inventory levels in real time and trigger responses to shortages, thus alleviating inventory pressures.

Customer Engagement

Building a strong online presence and gathering positive reviews from satisfied customers can help independent cell phone repair shops attract new customers and retain existing ones. CRM systems also play a pivotal role in this regard by maintaining a record of customer information and repair history, enabling the creation of tailored marketing offers.

Financial Considerations

Cell phone repair shops can achieve profit margins as high as 90%, depending on the effectiveness of their marketing and repair processes. Small to medium-sized repair shops with lower overhead costs and quality customer service can expect an average monthly profit ranging from $3,000 to $10,000 . However, the profitability of these shops is influenced by various factors, including the efficiency of operations and the ability to manage parts inventory economically.

Challenges and Solutions

The cell phone repair industry faces numerous challenges, such as high operational costs and intense competition from both official company repairs and other third-party services . Specialized software solutions can address these challenges by optimizing inventory management and automating various processes, which in turn can reduce costs and improve profitability. Additionally, adopting a tech-driven approach can help repair shops reconsider and improve their business models, ensuring a healthier bottom line and satisfied customers.

Common Materials Used for Screen Protectors

At the heart of the operation are high-quality raw materials. Most screen protectors are made from specialized materials like tempered glass, polyurethane, or thermoplastic polyurethane (TPU). Each material offers unique properties, such as scratch resistance, impact absorption, and flexibility. Manufacturers must meticulously select the appropriate material for various devices to cater to the diverse needs of consumers.

Plastic Screen Protectors

Plastic screen protectors are thin, lightweight sheets made from PET (Polyethylene Terephthalate) or TPU (Thermoplastic Polyurethane). These materials are pliable and can be cut to fit any device screen. They are typically less expensive than their tempered glass counterparts, making them a popular choice for those on a budget. While plastic protectors provide some level of protection against scratches, they do not offer the same level of impact protection as tempered glass protectors.

Types of Plastic Screen Protectors

There are two main types of plastic screen protectors, each with its own unique properties:

Tempered Glass Screen Protectors

Tempered glass screen protectors are widely regarded as the best and most protective kind of screen protector. They are made from a specially processed glass that is heated to high temperatures and then cooled rapidly to make it significantly stronger than regular glass. High-quality tempered glass contains multiple layers, including absorbent silicon, PET film, and binding adhesive. These layers allow for shock protection, meaning the screen protector is more likely to shatter than the actual phone screen when dropped.

Types of Tempered Glass Screen Protectors

2D Glass Protectors: These cover only the flat part of the screen and are ideal for flat-screen devices. 2.5D Glass Protectors: These have a slight curve at the edges, offering better coverage and protection for slightly curved screens. Tempered glass protectors are praised for their abilitvto mimic the feel of the original screen, providing excellent clarity and maintaining the touch experience. They are also anti-reflective, glare reducing, and fingerprint reducing, making them a superior choice for those seeking high-level protection.

Hydrogel Screen Protectors

In recent times, hydrogel screen protectors have also become popular. These protectors are noted for their flexibility and ability to heal minor scratches on their own. They are often used in conjunction with a hydrogel film cutter, which allows for precise customization and easy application. Hydrogel protectors offer a blend of the best properties of plastic and tempered glass, providing good protection while being thin and flexible enough to fit various devices.

Screen protectors come in a variety of materials, each offering different levels of protection and clarity. While plastic protectors are a budget-friendly option, tempered glass and hydrogel protectors provide superior protection and a better user experience.

Case Studies

Case Study 1: Mobile Repair Shop Efficiency Boost with Intelligent Film Cutting Machines

In a recent case study, a mobile repair shop in New York experienced significant improvements in operational efficiency and customer satisfaction after incorporating an intelligent film cutting machine into their workflow. The shop owner, who initially faced challenges with high turnover rates and prolonged repair times, reported a 30% increase in daily repair volumes post-adoption of the new technology. The intelligent film cutting machine enabled precise and rapid cutting of screen protectors and film covers, which previously had to be done manually, leading to faster service delivery and reduced customer wait times.

Case Study 2: Inventory Management Enhancement

Another compelling example comes from a mobile repair chain in California, which struggled with inventory management issues. The chain’s manager highlighted that manually cutting films often led to material wastage and inventory discrepancies.

By deploying intelligent film cutting machines, the chain managed to streamline their inventory processes. The precision of the machines reduced material wastage by 25%, and the integrated software provided real-time inventory updates, which significantly minimized discrepancies and optimized stock levels.

Case Study 3: Competitive Edge in a Saturated Market

A third case study focuses on a mobile repair shop in Texas competing in a highly saturated market. By integrating intelligent film cutting machines, the shop was able to diversify its service offerings. In addition to regular repair services, they started providing customized screen protectors tailored to specific customer needs. This new service not only attracted more customers but also distinguished the shop from competitors who did not offer customized solutions. The result was a 20% increase in new customer acquisitions within six months of implementing the new technology.

Case Study 4: Adapting to Changing Customer Preferences

Lastly, a mobile repair shop in Florida utilized intelligent film cutting machines to adapt to the changing preferences of their younger customer base. Millennials and Gen Z customers, who have a strong preference for personalized and quick service, were particularly drawn to the shop’s ability to offer same-day customizations for their devices, This adaptation resulted in a marked improvement in customer retention rates, with surveys indicating a 15% increase in customer satisfaction scores attributed to the availability of rapid, personalized services.

Challenges and Considerations

Initial Investment Costs

One of the primary challenges when adopting intelligent film cutting machines in mobile repair shops is the high initial investment costs. These machines are quite expensive due to the advanced technology integrated into them. Besides purchasing the laser cutter itself, businesses also need to invest in safety gear and materials required for the actual cutting process. This significant initial outlay can be cost prohibitive for some small businesses or individuals when compared to traditional methods that rely on hand tools like saws, which have much lower start-up costs.

Training and Skill Development

Successfully incorporating intelligent film cutting machines into a mobile repair shop also necessitates adequate training for staff. Providing consistent, flexible, and trans- parent training can significantly elevate a business. If finding a suitable trainer is challenging, businesses can have their most experienced staff develop training systems and hold sessions with new trainees. Utilizing a variety of resources, including detailed plans, guides, e-learning services, and online certifications, can help in creating a robust training program. Effective training not only enhances the skill set of the employees but also increases operational efficiency and customer satisfaction.

Economic Uncertainty and Market Dynamics

The current economic uncertainty presents both challenges and opportunities for mobile repair shops considering investing in new technology. While the instability can make it difficult to commit to substantial investments, it also encourages businesses to rethink their models and invest in technology that can improve efficiency and customer satisfaction. Moreover, the volatility in raw material prices and the impact of geopolitical conditions further complicate the decision-making process. These fluctuations can directly affect manufacturing costs and, consequently, the pricing and availability of cutting equipment.

Adoption of AI and Technological Integration

The integration of AI in manufacturing processes, including those used in film cutting machines, comes with its own set of challenges. Smaller shops may find the initial investment in AI technology substantial, but the long-term benefits, such as reduced operational costs and increased competitiveness, often justify the expenditure. AI can significantly enhance the efficiency of CNC machining by optimizing production workflows and reducing error rates. However, this transition requires a thorough understanding of AI capabilities and a strategic approach to integrating these technologies into existing operations.

Regulatory and International Trade Challenges

The globalization of economies facilitates the expansion of cutting equipment manufacturers but also intensifies competition. Companies must navigate international trade policies, tariffs, and currency fluctuations, all of which can affect pricing and market share. In such a complex international environment, collaboration and strategic partnerships become crucial for continued growth. Additionally, regulatory changes can have a substantial impact on market dynamics, requiring companies to stay abreast of legislative developments and adjust their strategies accordingly.

Future Trends

The Intelligent Film Cutting Machine Market is currently experiencing a phase of rapid and substantial growth, and this momentum is expected to continue from 2023 to 2031. Several key trends are shaping this market, influencing both consumer behavior and industry strategies. By understanding these trends, market participants can proactively position themselves for success.

One of the most significant emerging trends is the integration of automation and robotics into film cutting machines. This integration brings numerous benefits, including increased efficiency, accuracy, and speed, which are particularly important in industries such as aerospace and automotive manufacturing where precision is critical. The growing demand for customized cutting solutions that can perform a wide range of tasks with precision and speed is a primary driver of this trend.

Automation and robotics enable manufacturers to achieve higher levels of accuracy and repeatability, allowing for the production of more consistent and high-quality products. Additionally, automation reduces labor costs and enhances production efficiency, contributing to overall cost reduction and increased productivity.

Another trend is the adoption of advanced manufacturing technologies such as additive manufacturing or 3D printing. These innovations have significantly reduced the costs and time associated with custom tooling, allowing many shops to transition to in-house tooling production and refurbishment instead of relying on third-party services. This shift not only cuts costs but also improves the agility and responsiveness of manufacturing operations.

Furthermore, the rise of the Industrial Internet of Things (IIoT) is revolutionizing the manufacturing landscape by increasing interconnectedness between different ma- chines and equipment on the factory floor. This unprecedented level of connectivity enhances job flexibility, opens up new networking opportunities, and allows for more efficient integration of customer feedback into new products. The IIoT is still in its infancy, but it already shows promise in prototype design and the seamless operation of interconnected systems.

Artificial Intelligence (AI) is another technological frontier that is reshaping the market. AI-enhanced manufacturing offers several long-term benefits, including reduced operational costs, increased competitiveness, and optimized production workflows. Although initial investments in AI technology can be substantial, particularly for small- er shops, the cost of powerful AI tools is often justified by the significant improvements they bring to manufacturing processes. AI is driving the transition to Industry 4.0, characterized by intelligent and interconnected manufacturing systems.

Finally, the COVID-19 pandemic has underscored the importance of resilience in the supply chain. While it initially caused delays in production and delivery, the market has shown signs of recovery as the global economy improves. The demand for film cutting machines is expected to rise, particularly in the construction, automotive, and aerospace sectors.

Comments

Mercedes-Benz Class C C200L Navigation Temper Glass

Our W206 C-Class Screen Protector offers superior protection for your C200L’s 11.9-inch display.

How to Remove Screen Protector from iPhone?

By following these steps, you can safely remove and replace your iPhone’s screen protector, ensuring your device remains in top condition.

How to Get Rid of Air Bubbles in Screen Protector?

By following these guidelines, you can ensure your screen protector is applied correctly and remains bubble-free, enhancing both the appearance and functionality of your device.

Investing in a Smart Privacy Screen Cutting Machine-What You Need to Know

Investing in smart privacy screen cutting machines provides a strategic opportunity for the company to meet the growing demand for customized privacy solutions in both the residential and commercial sectors, while leveraging technological innovation and sustainable practices to enhance product competitiveness.

How to Vet a Screen Protector Factory Before Partnering

When establishing a screen protector manufacturer partnership, it is critical to fully review the factory’s quality, risk, compliance, and communication strategies to ensure product quality and successful collaboration.

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.