How Screen Protector Factories Ensure Product Quality and Durability

Table of Contents

Extract

Summary

Lead Section: How Screen Protector Factories Ensure Product Quality and Durability Screen protector factories employ advanced manufacturing processes and stringent quality control measures to ensure the durability and reliability of their products. As essential accessories for smartphones and other devices, screen protectors play a crucial role in safeguarding screens from scratches, cracks, and other damage, making the assurance of quality paramount in a competitive market. The increasing reliance on mobile devices for both personal and professional use has heightened consumer awareness regarding the importance of selecting high-quality screen protectors, thereby elevating the industry’s focus on quality assurance. The manufacturing process integrates innovative technologies and meticulous inspections, emphasizing not only the functional aspects of the products but also environmental sustainability. Manufacturers implement comprehensive quality assurance (QA) strategies, including multi-stage quality checks and compliance with international standards, to mitigate defects and enhance product performance. A blend of automated processes and skilled manual inspections allows factories to identify and address potential issues, ensuring that products meet rigorous quality benchmarks before reaching consumers. Despite the advancements in technology, challenges persist in maintaining consistent quality across various manufacturing facilities. Issues such as variability in production standards, the complexity of processes, and the need for ongoing employee training can complicate quality assurance efforts. Furthermore, the industry’s increasing emphasis on sustainability has prompted manufacturers to adopt eco-friendly practices, integrating recycled materials into their production lines while simultaneously upholding product integrity. Prominent controversies surrounding screen protector manufacturing often relate to quality discrepancies and the ethical implications of material sourcing. As consumers become more discerning, manufacturers must navigate these challenges while ensuring that their products are not only reliable and durable but also environmentally responsible. By addressing these concerns and continuously enhancing their quality control systems, screen protector factories are striving to meet the evolving expectations of consumers and contribute to a sustainable future in the industry.

Manufacturing Process

Overview

The manufacturing process of screen protectors is a meticulous operation that integrates advanced technology and strict quality control measures. This process not only focuses on the functionality of the product but also emphasizes environmental responsibility and sustainability.

Preparing the Production Line

Before production begins, a well-prepared production line is crucial. This phase includes the careful selection of materials and acquisition of advanced equipment to ensure efficiency. For instance, manufacturers apply anti-glare coatings to enhance visual clarity and reduce reflections, making them essential for users in bright environments

. Additionally, an oleophobic coating is applied to repel oils and fingerprints, helping to maintain a clean and clear display.

Quality Control Measures

Maintaining quality throughout the manufacturing process is vital. Manufacturers implement both incoming and outgoing quality control measures, checking raw materials upon arrival and finished products before they leave the factory

. This includes developing quality control checklists that define acceptable standards for the product, which are critical for reducing defects and ensuring consistency.

Human Element in Quality Control

Despite the presence of advanced machinery, skilled workers play a significant role in the quality assurance process. Each product undergoes thorough manual inspection to identify defects or imperfections before it reaches consumers

. This human oversight is essential, especially when automated processes are involved, as it helps catch any issues that machines might overlook.

Specialized Treatments

The glass used in screen protectors undergoes several specialized treatments. For instance, high-quality silica sand is melted to form molten glass, which is then subjected to a chemical strengthening process involving potassium salt baths. This treatment enhances the strength and durability of the glass

. Afterward, the glass is cut and polished to precise dimensions, ensuring it meets the required specifications.

Environmental Considerations

Modern manufacturing practices also prioritize sustainability. Factories are increasingly replacing virgin plastic with recycled materials, thus reducing their ecological footprint. Innovations include using biobased materials for product trays and eliminating unnecessary plastic components from the production process

. These efforts reflect a growing commitment to not only producing high-quality products but also minimizing environmental impact.

Quality Assurance Measures

Quality assurance (QA) measures in screen protector manufacturing are critical for ensuring product performance, reliability, and safety. These measures aim to prevent defects before they occur, incorporating various systematic tools and methodologies to analyze and enhance production processes.

Preventive Strategies

QA involves a comprehensive approach to minimize the potential for defects. This includes using statistical tools such as histograms, control charts, and Pareto charts to identify trends and inform process improvements

. By implementing rigorous QA practices, manufacturers can effectively manage quality throughout the production cycle, leading to enhanced operational performance.

Compliance with Standards

Screen protector manufacturers adhere to international quality standards, which serve as frameworks for best practices in production. These standards ensure that materials and processes meet specified quality benchmarks, thus reducing the risk of product failures

. For instance, quality management standards are instrumental in streamlining operations and enhancing product durability.

Multi-Stage Quality Checks

To maintain high standards, manufacturers often conduct multiple checks throughout the production process. This includes material quality inspections, assembly line evaluations, and final shipping assessments

. By ensuring that each stage meets established quality criteria, manufacturers can detect and rectify issues early, thus preventing defective products from reaching consumers.

Testing and Validation

Rigorous testing is integral to QA measures. Screen protectors undergo a variety of tests, including impact resistance, abrasion, and temperature fluctuations

. These evaluations simulate real-world conditions to ensure that the product can withstand everyday use without compromising its integrity. Testing not only helps validate product performance but also reinforces the manufacturer’s commitment to quality.

Data-Driven Insights

Collecting data on product quality is vital for auditing manufacturing processes. By analyzing information on cycle times, part counts, and defect rates, quality managers can identify manufacturing bottlenecks and waste

. This data-driven approach enables continuous improvement in QA systems, ensuring that quality standards are not only met but exceeded.

Customer Assurance

Many manufacturers provide warranties or guarantees as part of their QA measures. This includes offering replacements for defective products within a specified timeframe, thereby instilling confidence in customers regarding product reliability

. Such policies are an extension of the QA commitment, enhancing customer satisfaction and brand loyalty.

Technology and Innovation

Advanced Touch Screen Manufacturing

The production of touch screens has evolved significantly due to innovative approaches that revolutionize their fabrication on ultrathin glass substrates. This modern method employs a combination of advanced technologies and materials, including functional coatings on the glass surface, leading to several advantages over traditional manufacturing techniques. Notably, the process is cost-effective, allowing manufacturers to optimize production costs while ensuring high-quality outputs that meet industry standards

.

Fabrication Process

The capacitive touch screen manufacturing process involves multiple crucial steps, beginning with substrate preparation. The glass substrate, which serves as the foundation for the touch screen, is meticulously cleaned to eliminate impurities, ensuring an optimal surface for coating application. A transparent conductive layer, typically made of indium tin oxide (ITO), is then deposited using methods such as sputtering or chemical vapor deposition. This layer is vital for enabling conductivity and responsiveness during touch interactions

.

Photolithography Techniques

The application of photolithography is fundamental in the production of capacitive touch screens. The process begins with thorough cleaning to remove contaminants, followed by the deposition of a thin ITO layer. Subsequent heating enhances the adhesion and conductivity of the ITO layer while also eliminating residual solvents

. Accurate alignment between layers is critical, and various optical or mechanical methods are employed to achieve this precision. Once aligned, the curing process solidifies the ITO layer, optimizing its electrical conductivity.

Layer Integration and Quality Control

Once the initial layers are prepared, the touchscreen sensor layer is laminated with a transparent adhesive onto the cover glass. This lamination is conducted using vacuum technology to remove air bubbles, ensuring seamless integration and preventing disruptions in touch sensitivity

. Throughout the manufacturing process, rigorous quality control measures are implemented. Each product undergoes manual inspections to identify any defects, thus maintaining a high standard of product quality and durability.

Sustainable Practices in Manufacturing

The adoption of sustainable practices has also become a priority for modern screen protector factories. Many manufacturers are increasingly utilizing recycled glass and eco-friendly materials, aligning their operations with environmental sustainability goals. These initiatives not only contribute to reduced waste but also enhance the overall quality and appeal of the final products

. The combination of innovative technologies and a commitment to sustainability positions these factories at the forefront of the industry, capable of producing high-quality screen protectors that meet consumer demands while being environmentally responsible.

Challenges in Quality Assurance

Quality assurance (QA) in screen protector manufacturing faces several challenges that can impact the overall effectiveness of quality control programs. These challenges often stem from the complexity of production processes, varying industry standards, and the need for strict adherence to specifications.

Complexity of Production Processes

Manufacturing screen protectors involves intricate processes that require precision and consistency. Any deviation from established procedures can lead to defects. For instance, factors such as equipment calibration, operator skill levels, and material quality all play a crucial role in maintaining product integrity.

Moreover, not all manufacturers are equipped with the same tools or processes, which complicates the selection of production partners and the standardization of quality metrics across different facilities.

Variability in Standards

Another significant challenge is the variability in quality standards across different markets and customer expectations. Manufacturers targeting high-end markets must adhere to stricter quality controls, as customers in these segments expect flawless products. Conversely, products aimed at budget-conscious consumers may not require the same level of scrutiny, leading to potential inconsistencies in quality assurance practices across different product lines.

This discrepancy can complicate the implementation of a unified quality management system.

Data Collection and Analysis

Effective QA relies heavily on data collection and analysis to identify trends and potential issues. However, gathering accurate data can be problematic, especially in a fast-paced production environment. Many companies utilize digital tools to collect data on part quality and operational performance, yet integrating these tools into existing processes can pose challenges. For example, data must be analyzed to pinpoint bottlenecks and waste, but if the data is inaccurate or incomplete, it can lead to misguided quality initiatives.

Employee Training and Engagement

Embedding a culture of quality within an organization is essential but often difficult to achieve. Employees must be well-trained and fully understand the quality standards and benchmarks necessary for product excellence. Training programs that simulate real-world scenarios can enhance employees’ ability to identify and address quality issues, but developing and maintaining such programs requires time and resources.

Additionally, without active engagement from all team members, the effectiveness of QA initiatives may diminish.

Regulatory Compliance

Finally, regulatory compliance poses a significant challenge for manufacturers, particularly in the pharmaceutical and electronics sectors, where standards are stringent. Companies must navigate complex regulations to avoid costly fines and ensure their products meet industry standards.

This not only necessitates a thorough understanding of applicable regulations but also demands continuous monitoring and adjustment of quality assurance processes to maintain compliance.

Case Studies

Guangzhou Boyi Telecom

Guangzhou Boyi Telecom, established in 1998, specializes in manufacturing and exporting mobile phone accessories, including screen protectors. The company operates an ISO 9001-certified factory in Shenzhen, Guangdong, producing over five million items monthly

. Their strict quality control system ensures that each product meets high standards. Before shipping, products undergo thorough inspection processes that combine advanced machinery with manual checks by skilled workers to identify any defects. The company maintains a competitive shipping timeline, dispatching products within 3-5 days and custom orders within 7-30 days using major carriers like DHL and FedEx.

Dongguan Qicaitong Plastic Technology

Another notable example is Dongguan Qicaitong Plastic Technology, which focuses on ODM and OEM services for mobile accessories. This company boasts a monthly output capacity of 10 million units and is also ISO 9001 certified

. Their production facility emphasizes sustainability, employing recycled and biobased materials in its manufacturing process. The factory maintains a 7-day lead time for samples and approximately three weeks for bulk orders, ensuring timely delivery without compromising quality.

Guangzhou C&T Industry Company Limited

Founded in 2002, Guangzhou C&T Industry Company Limited has positioned itself as a leading manufacturer of mobile phone cases and accessories. With certifications including ISO 9001 and BSCI, the company exports nearly 100% of its products to international markets, primarily North America and Europe

. Their production capabilities cover a range of materials and types, with an average lead time of 15 days for orders. Quality assurance practices include 100% inspection before shipment, which reinforces their commitment to delivering reliable products.

Shenzhen Luphie Technology

Shenzhen Luphie Technology showcases a strong commitment to quality and sustainability in their manufacturing processes. Operating in a cleanroom environment, every product undergoes meticulous manual inspection to ensure it meets rigorous quality standards

. The company has also integrated environmentally friendly practices, such as using RPET instead of virgin plastic and adopting biobased materials in their products. This blend of advanced technology and human oversight highlights the importance of a comprehensive quality control strategy in the screen protector industry. These case studies exemplify how various factories implement stringent quality control measures, advanced manufacturing processes, and sustainable practices to produce high-quality screen protectors and mobile accessories.

Consumer Education

Importance of Screen Protectors

Screen protectors are essential accessories for smartphones and other devices, safeguarding screens from scratches, cracks, and other potential damage. Given the increasing reliance on smartphones for personal and professional activities, choosing a quality screen protector has become a critical decision for consumers.

By investing in the right protector, users can enhance the longevity of their devices while maintaining their aesthetic appeal.

Types of Screen Protectors

Consumers have a variety of options when it comes to screen protectors. Tempered glass protectors are popular for their durability and clarity, while film-based protectors offer flexibility and a lighter touch against the screen. Understanding the differences between these types allows consumers to make informed choices based on their individual needs and lifestyle.

Retail and Direct Sales Channels

Screen protectors are available through multiple retail channels, including online marketplaces, electronics stores, and specialized accessory retailers. Many manufacturers also adopt a direct-to-consumer sales model via their websites, fostering closer relationships with customers. This approach not only allows for personalized support but also facilitates feedback that can be used to improve product offerings.

Eco-Conscious Choices

In recent years, a growing number of manufacturers have embraced eco-conscious initiatives, such as using sustainable packaging and carbon-neutral shipping options. This trend reflects a commitment to reducing environmental impact and appeals to consumers who prioritize sustainability in their purchasing decisions.

Quality Control and Standards

When selecting a screen protector, consumers should be aware of the quality control measures that manufacturers employ. Adhering to recognized standards, such as ISO certifications, can enhance product reliability and customer satisfaction.

By understanding these quality benchmarks, consumers can feel more confident in their purchasing choices, ensuring they are investing in products that meet their expectations for durability and performance.

Educating Consumers

Brands can bolster consumer education by providing clear information about the benefits and features of their screen protectors, along with guidelines for installation and care. Empowering consumers with knowledge not only improves their purchasing experience but also builds trust in the brand, encouraging repeat business and positive word-of-mouth recommendations.

Comments

How to Remove a Glass Screen Protector?

By following these steps, you can safely remove and replace your glass screen protector, keeping your device in top condition.

Eco-Friendly Practices in Screen Protector Manufacturing

Eco-friendly practices in screen protector manufacturing aim to reduce environmental impact and meet growing consumer demand for sustainability through innovations in materials and processes.

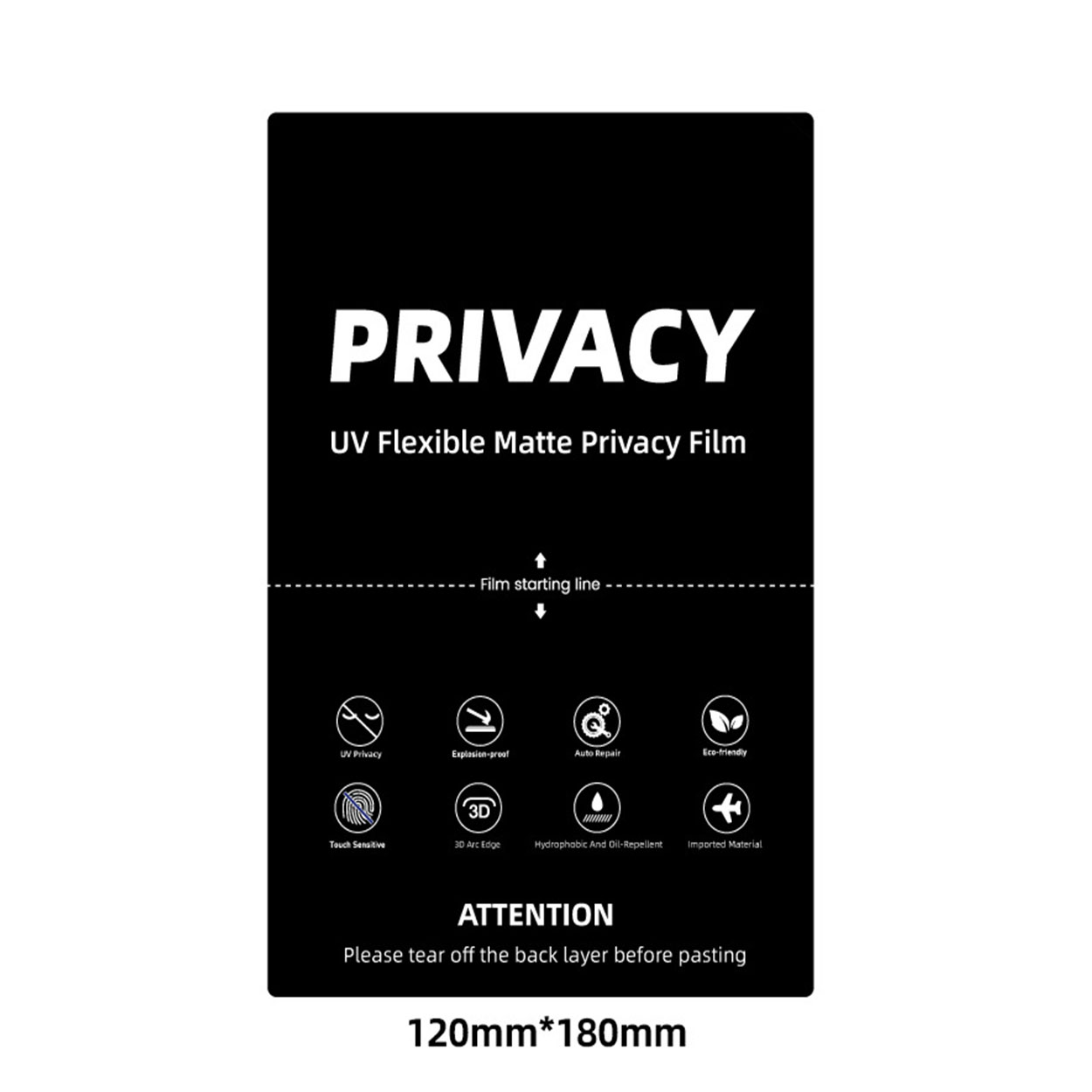

Intelligent UV Matte Privacy Screen Protector For Cutter

Discover the future of mobile protection with our guide to screen protector cutting machines. Learn how film cutters create custom screen protectors

Do Phone Repair Shops Go Through Your Phone?

By following these guidelines, you can ensure that your phone repair experience is both secure and satisfactory.

UV Light Curing Machine For Phone Protector

Quick Curing: Cures the screen protector in less than 5 minutes.

Superior Protection: Offers 3H hardness, explosion-proof, and drop-proof protection.

Disinfection: UV light sterilizes the phone, providing added hygiene.

Simple Process: Easy to use with minimal effort and a perfect finish every time.

With its advanced features, ease of use, and superior protective qualities, this UV Light Curing Mobile Phone Film Machine is the ultimate solution for ensuring your mobile phone remains safe, clean, and scratch-free!

Tags

Find All knowledge and trends from our blog, get the wholesale price and best quality from our factory.

What Film Cutting Machine and Its Application

Film cutting machines have played a crucial role in the evolution of filmmaking and various industrial processes by enabling precise cutting and splicing of film materials.

What Is a Screen Protector Cutting Machine?

A screen protector cutting machine is a specialized device designed to produce custom-fit screen protectors for various electronic devices, including smartphones, tablets, smartwatches, laptops, and monitors.

How Mobile Phone Screen Protector Cutting Machine Work?

A mobile phone screen protector cutting machine is a sophisticated device designed

to produce customized screen protectors for various digital devices with high preci

sion and efficiency.

Characteristics of Mobile Phone Tempered Glass and Mobile Phone TPU Screen Protector

Thermoplastic polyurethane (TPU) screen protectors are flexible, durable, and

self-healing plastic films designed to protect electronic device screens from

scratches, impacts, and other potential damages.

Revolutionize Device Protection with Screen Guard Cutting Machine

Whether you possess a smartphone, tablet, or smartwatch, this versatile machine accommodates a vast array of devices. It seamlessly adapts to the dimensions of your gadget, offering a custom fit that generic protectors can’t match.

Screen Protector Lifetime Warranty

A screen protector lifetime warranty is a guarantee provided by manufacturers that

promises to repair or replace a screen protector for the lifetime of the product, under specific terms and conditions.